Cell culture and bioprocessing conventional wisdom remains a hurdle for the wider adoption of more precise tools. It has been more than 60 years since any real progress has been made towards creating a more accurate and reliable way of performing cell culture monitoring to better understand the effects of things like pH and oxygen at the pericellular level. At SBI, we’re developing optical sensing technologies that unlock the “black box” of cell culture to bring actionable insights to scientists…

Upstream Processing

Measuring Cell Density in HyPerforma S.U.B.s with ABER Futura neotf

Single-Use Sensors

Monitoring critical process parameters (CPPs) and key performance indicators in bioreactor control systems is crucial to ensure proper cell growth and protein production. Today, most of the major biopharmaceutical companies employ capacitance measurement, in R&D and through process development to manufacturing. Owing to the increased use of single-use bioreactors and building on Aber’s experience with single-use capacitance sensors, the latest Futura neotf single-use capacitance sensors have been specifically developed for integration into Thermo Fisher Scientific bioprocess containers (BPCs) for use…

Cell Banking in the Spotlight: Advising Biologics Developers About Cell Bank Preparation and Characterization

Living cells are at the heart of biotechnology, and cell lines for production and testing of biopharmaceuticals are highly valuable assets. The process of banking cells generally moves from development of a research cell bank (RCB) based on a clone of interest to establishment of a master cell bank (MCB), from which working cell banks (WCBs) can be produced. Especially for biotechnology startups, preparation of an MCB can involve a significant jump from work performed in standard laboratory conditions to…

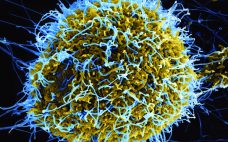

Avenues for Innovation: The Latest in Cell-Line Engineering and Development

Plato wrote in ancient Greece that “our need will be the real creator,” which transformed over time into the English proverb, “Necessity is the mother of invention.” Advancements in medicine and biomanufacturing technology in 2020 have epitomized that idea. Even as technologies such as mRNA vaccines have rocketed into the public’s awareness, biomanufacturing experts have worked behind the scenes with renewed vigor spurred on by hard lessons from the pandemic. Cell-line development and engineering are no exception. Already undergoing a…

Increasing Expression Titers: New Technologies Could Help Other Cell Lines Catch Up to CHO

Fang Tian is a lead scientist and head of cell biology research and development at the American Type Culture Collection (ATCC) in Manassas, VA. She is a member of both the International Cell Line Authentication Committee (ICLAC) and the US technical advisory group for the ISO/TC276 technical committee. At ATCC, she oversees preparation, authentication, characterization, quality control, and cryopreservation of more than 3,400 accessioned animal cell lines and hybridomas in the cell biology general collection. She holds a PhD in…

Engineering Alternatives: Modern Technology Enables Expression System Developers to Think Beyond CHO Cells

Major biopharmaceutical companies are teaming up with academics and the Bill & Melinda Gates Foundation to develop new biomanufacturing cell lines and methods. The project — known as the AltHost Consortium — is exploring innovative ways to produce biologics and vaccines for clinical usage in diseases from diabetes to cancer. Lead researcher J. Christopher Love at the Massachusetts Institute of Technology (MIT) likens this precompetitive, open-access collaboration to the early days of the biopharmaceutical industry. “When biomanufacturing first emerged as…

Cell-Free Expression: A Technology with Truly Disruptive Potential

Bioprocess engineer Beatrice Melinek is a postdoctoral research fellow at University College London’s Future Targeted Healthcare Manufacturing (FTHM) Hub, where she focuses on the use of cell-free protein synthesis (CFPS) as a platform for distributed production of stratified biotherapeutics. Previously Melinek specialized in purification of viral vectors and vaccines, with an engineering doctorate (EngD) in biochemical engineering and postdoctoral experience in UCL’s hematology department developing a new chromatography-based analytical method for measuring empty and full adenoassociated virus (AAV) capsids. She…

Technologies and Innovations: A Discussion with Selexis SA

Pierre-Alain Girod is chief scientific officer (CSO) for Selexis SA. He holds a PhD in plant biochemistry from the University of Lausanne in Switzerland and completed a postdoctoral fellowship at the University of Wisconsin in Madison, WI, on the degradation of proteins by the ubiquitin pathway. Girod returned to Switzerland in 1993, where he discovered a family of sequences that are involved in the epigenetic regulation of genes. That discovery subsequently has been used to express therapeutic proteins in the…

eBook: Bioreactor Sensors —

Inside the Dynamics of Cell Culture

Cell culture monitoring can fall into something like a “black box” conundrum. Efforts to measure key parameters such as pH, glucose, and even cell density require sampling and removal of the contents from a bioreactor. But that procedure can expose both a process and an operator to contamination risks. Emerging bioreactor sensors are designed to address some of those challenges, but the rapid adoption of single-use technologies and the rise of perfusion cell culture have presented obstacles to their implementation.…

Rapid Development of Viral Vector Production Processes: Iterative Parameter Optimization

With recent developments and successes in cell and gene therapy, the biopharmaceutical industry is facing increased demand for safe and efficient delivery systems (1). Viral vectors, including adenoviruses (AV), adenoassociated viruses (AAV), and lentiviruses (LV), are among the most common delivery agents because they infect mammalian cells efficiently. Suspension cultures have become a popular choice for robust and scalable viral manufacturing systems. Using stable cell lines that integrate all or part of the viral production elements adds further benefits by…