Clients often come to us with protein conjugation process needs that can require development of new and innovative methods to assure process validation for conformance manufacturing. Our staff utilizes state-of-the art technologies and instrumentation for a wide range of protein drug manufacturing challenges. These scientists provide the expertise and experience needed to develop accurate and highly reliable assay methods designed specifically to assure successful conformance manufacturing of their protein-hapten or protein-drug conjugate. This white paper illustrates just one example of…

Sponsored Content

Use of the ambr®250 in Combination with High-Throughput Design and Analysis Tools for Rapid, Scalable USP Development

There have been many recent advances in high throughput (HT) technologies for upstream development, enabling processes to be developed in a fraction of the time compared with conventional methods. However, when applying this technology to biotherapeutic drug development, the suitability of the systems for developing large scale manufacturing processes and meeting regulatory demands needs to be demonstrated and ensured. Inclusive approaches encapsulating platform expression systems and fermentation technologies, parallel bioreactor systems, high throughput analytics and sophisticated design and data handling…

Welcome

An international group of experts met last year and exchanged their latest findings in bioprocessing technology at the Sartorius Stedim Biotech Upstream and Downstream Technology Forum, held at Sartorius College in Göttingen, Germany. This conference continues a more than decade-long tradition of bringing together leaders in bioprocess development and biomanufacturing operations from the world’s leading biopharmaceutical companies to explain how they are addressing the most important industry challenges. Although conference presentations were divided as related to either upstream processing, downstream…

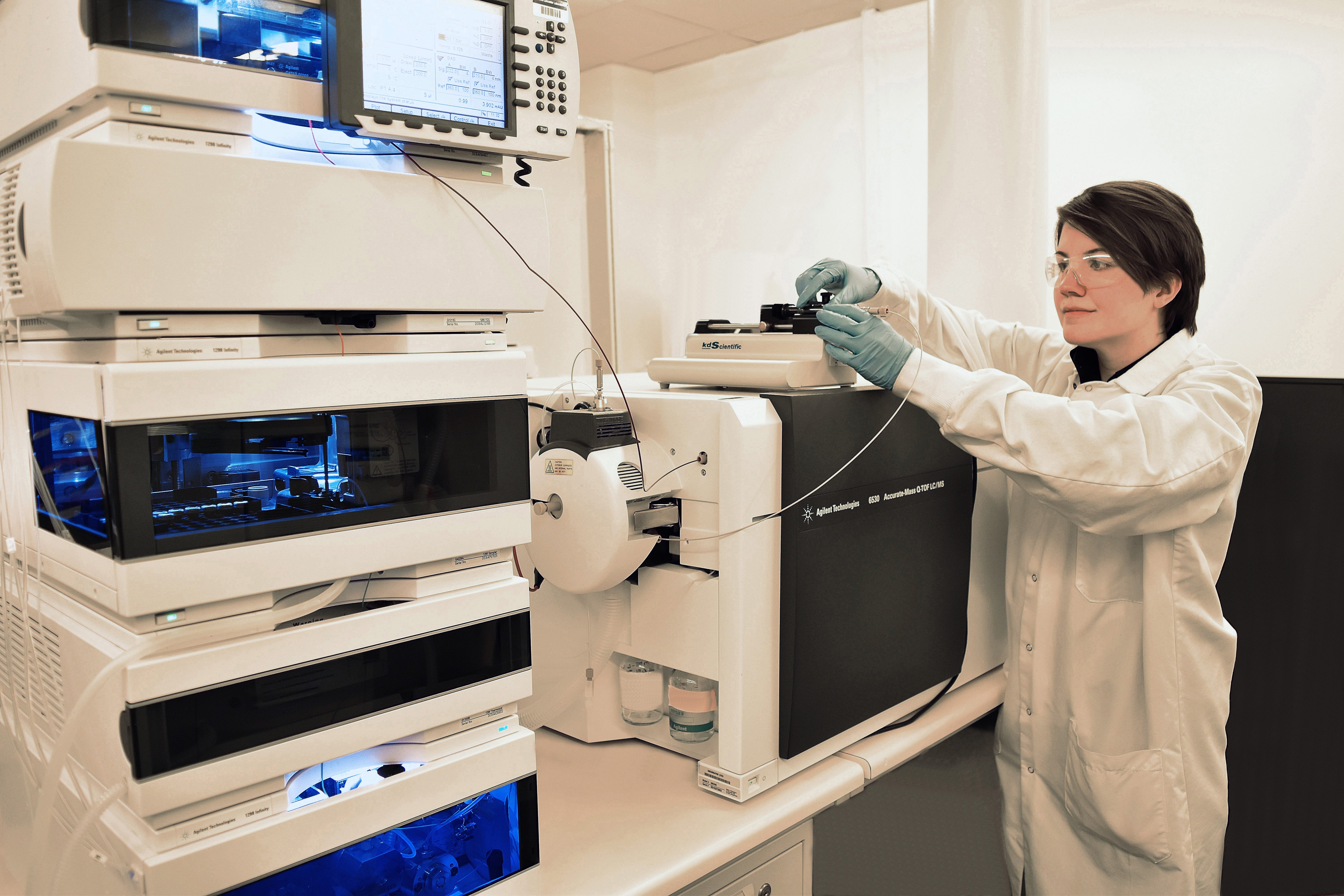

Extractable and Leachables Studies: Designed and Performed to Meet all Intended Needs

Since the FDA released their Container Closure Systems for Packaging Human Drugs and Biologics guidance in 1999, evaluation of final packaging components for extractables and leachables has become the expectation within the industry. Additionally, the increase in the use of single-use systems in manufacturing has drawn scrutiny as another potential source of extractables and leachables. Extractables are compounds that can be extracted from a product contact material under exaggerated conditions such as elevated temperatures, extended storage times, or exposure to…

Filling Industry Gaps with Dedicated Cell Therapy Fluid Transfer Sets

For years, availability has cornered cell therapy manufacturers into utilizing transfer sets intended for other industries and applications. These transfer sets or accessory sets are not designed for cell therapy, and therefore lack key requirements, essential to clinical and commercial manufacturing. Many current personalized cell therapies are highly manual in practice, and require numerous ancillary components and handling steps. Modifications to these processes further complicate this inherently challenging process. These deviations impact the reproducibility of the manufacturing platform, as well…

Improving Protein Folding Control and Scalability Using imPULSE Mixing Technology

This webcast features: Anthony Hawrylechko, Director of Microbial Bioprocess, Cytovance Protein folding by dilution is a common approach used in the manufacturing of biologics derived from microbial expression systems. This typically involves the solubilization of a washed inclusion body preparation containing the concentrated product polypeptide with a strong chaotrope or detergent solution. The denatured, inactive product solution is then diluted into a combination pH and red/ox buffer solution. Within this environment, the molecular diffusion rates of chaotrope, buffer components, and…

Effective Deployment of OPUS Pre-Packed Chromatography Columns for Bench-Scale Process Development and Process Validation

This webcast features: Tim Schroeder, Director, Product Management at Repligen GmbH Formerly Atoll pre-packed columns, OPUS® pre-packed chromatography columns for process development are used in all steps of downstream development, including screening, process validation and viral clearance, scale up and sample preparation. This webcast will demonstrate how OPUS® ValiChrom Columns, glass pre-packed columns that are exact scale-down models of corresponding full-scale chromatography columns, are ideal for process validation including viral clearance. It will also demonstrate how OPUS® RoboColumns®, miniaturized columns…

Characterization and Engineering Performance of the Allegroâ„¢ STR 2000 Single-Use Stirred Tank Bioreactor

Process performance in bioreactors is strongly influenced by the efficiency of bulk fluid mixing and the oxygen mass transfer coefficient (kLa). The success of traditional stainless steel STR systems lies in their direct impeller driven agitation that can deliver a wide range of specific power inputs to the fluid. The Allegroâ„¢ range of single-use stirred tank bioreactors has adopted this direct driven impeller technology, which allows a wide range of specific power inputs to be achieved. In addition, modifications to…

A Scalable Immobilized Metal Affinity Chromatography Resin for Process Purification

Downstream process purification of proteins requires a resin with optimized bead size for ideal pressure/flow properties and decent dynamic binding capacity (DBC) that provides production efficiencies and good process economics. Our newly developed metal chelate affinity resin — Nuvia™ IMAC — provides the mechanical strength, pore structures, ligand density, and particle size distribution required for an operation run at 300 cm/hr with a DBC of > 40 mg/ml at < 2 bar column backpressure. Protein purification can efficiently be scaled…

Reducing the Complexity of Custom Single-Use Assemblies

Single-use technology (SUT) has been adopted on a global scale since its introduction 20 years ago. Its benefits are well-recognized, and it is a key enabling technology in today’s biopharm world. Thousands of single-use products are now on the market and entire processes are being run in single-use systems. Historically, end users have been encouraged to produce ‘customized’ single-use solutions for each individual application. While this can give the user exactly what they want, it can be at the expense…