This webcast features: Patrick Gurgel, Head of Research & Development, Prometic Bioseparations. Affinity chromatography has a long history of use in bioprocesses and is a powerful tool in making industrial processes more efficient by reducing the number of steps necessary to achieve the desired target purity and yield. It is common, however, for teams to only consider affinity chromatography as an alternative once other options have been considered, evaluated, and discarded, which translates into a need to develop affinity adsorbents…

Sponsored Content

From 1mL-100L: Consistent Chromatography Performance Across Multiple Sizes of Pre-Packed Columns

This webcast features: Fletcher Malcom, Product Line Leader, Repligen With the increasing use of pre-packed columns in protein separations, it is critical to demonstrate consistent chromatographic performance at different scales. This allows for seamless process scale-up and scale-down. This webinar will show how chromatography separation remains unchanged across different OPUS® Column sizes. Performance results obtained with bench-scale columns (≥1mL column volume) are demonstrated to be scalable to production sized columns (≤100L column volume). Watch the recorded webcast below.

Smart Modular Package Units for Single-Use Processing: Addressing Cost, Speed, and Flexibility Challenges in Biologics Manufacturing

How to reduce costs, while still increasing speed, and flexibility in biologics manufacturing currently represent major issues for the biopharma industry. In this article, Burkhard Joksch, Product Manager Bioprocess Automation and Stuart Tindal, Product Manager FlexAct® Platform at Sartorius Stedim Biotech GmbH, detail the evolution of automation for single-use technology towards modular packaging units. They also including case studies of how these units can be used in real life cGMP processes, as well as explain the manufacturing and industry benefits…

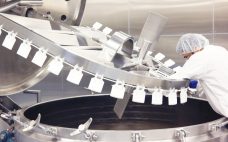

High-Viscosity Mixing: Choosing the Right System for the Job

Manufacturers of topical ointments, gels and lotions for BioPharma, personal care and other high-viscosity products face critical product quality challenges in their mixing processes. The better these challenges are understood, the more specific the design and configuration of processing equipment can be, to optimize product quality and maximize plant productivity. Unfortunately, conventional mixing systems may limit the ability of product manufacturers to optimize productivity and efficiency. The inefficiency of conventional dual-agitated vessels, multiple mixing vessels, and the operational complexity of…

Understanding Critical Measurement Parameters in Vaporized Hydrogen Peroxide Bio-decontamination

Effective destruction of microorganisms can be achieved with vaporized hydrogen peroxide, a safe and effective bio-decontamination method in many applications, including medical device manufacturing and healthcare procedure room decontamination. However, to ensure efficacy, it is necessary to monitor the level of hydrogen peroxide during the bio-decontamination. Measurement parameters are interdependent; temperature affects humidity, as does H2O2 concentration. These in turn will determine the point in time that condensation will occur, a critical phase. Some manufacturers of bio-decontamination chambers or isolators…

Shortening Timelines and Reducing Headaches by Developing a Clinical Trial Strategy Earlier During Drug Development

This webcast features: Kristen DeVito, Global Director, Clinical Supply Services, Catalent Pharma Solutions Biologic clinical trials can be complex with many factors to consider. Understanding your specific needs and developing a plan early on during drug development can reduce delays and missteps during clinical trials. This presentation will discuss: How protocol design can impact clinical supply strategy Which clinical supply variables are most likely to be on the critical path Proactive steps to ensure continuity of supply and reduce the…

Don’t Just Pass the Baton: Comprehensive Capabilities and Parallel Processes Accelerate Biologic Development Timelines

Biologic drug development from DNA to commercialization involves many moving parts, which can be difficult for companies to coordinate. For example, there are often new expert stakeholders introduced during each stage of development, leading to inefficiencies and confusion. However, with deep expertise and effective communication between teams, companies can reduce risk and shorten time to clinic and, subsequently, to market. In this webinar series, three biologics subject matter experts will discuss critical considerations in their respective areas of expertise: drug…

Qualitative and Quantitative Host Cell Protein Analysis Using Mass Spectrometry

Host cell proteins (HCPs) originate from host organisms that are used to produce biopharmaceutical products. They are in-process contaminants that must be minimized during downstream process operations. According to regulatory agencies, the maximum permitted level of total HCP in a biopharmaceutical product is 100 ng per mg (100 ppm) (1). HCPs can decrease drug efficacy and pose a risk to patient safety because they can bring on undesirable immune responses. Thus, HCPs are a critical quality attribute that should be…

Using Slope Spectroscopy Methods: Risk Assessment and Cost Savings

The biopharmaceutical industry’s need for rapid, accurate concentration measurements of protein-containing products is critical. The protein-concentration assay measures ultraviolet absorption at 280 nm (A280) and usually is performed both as an in-process test and for product-release testing. The SoloVPE system can analyze samples across a wide range of target concentrations without the need for labor-intensive and error-prone dilutions. Slope Spectroscopy methods provide companies with a universal platform for determining protein concentration for all in-process, clinical, and commercial methods. During in-process UV…

The Changing Landscape of Single Use in Bioprocessing: An Interview with Stefan Schlack and Jean-Marc Cappia

Single use in bioprocessing has changed significantly in recent years. To find out how a leading supplier to the biopharmaceutical industry is redefining its technology to align with new market challenges, science writer, Sue Pearson, had the opportunity to interview Stefan Schlack, Head of Bioprocess Marketing, and Jean-Marc Cappia, Head of Segment Marketing Vaccines, both at Sartorius Stedim Biotech (SSB) in Goettingen, Germany. Redefining Single Use Pearson: Sartorius Stedim Biotech is a recognized leader in single-use technology, and you’ve recently…