Tubing for Single-Use bioprocess and pharmaceutical applications has particular requirements. Among them are the ability to withstand various sterilization processes, the delivery of favorable test results regarding extractable substances, and the absence of animal-derived ingredients. Flexibility, permeability, performance in pumps, and welding and sealing capabilities are also common considerations. Additionally, these critical industries should be aware of the environment in which the tubing is manufactured, association standards that must be met and costs. One of the most important concerns involves…

Sponsored Content

Solving Viscosity in Automated Particle Imaging

Micro-Flow Imaging™ (MFI) easily detects particle size and morphology on a wide range of particle contaminants. And when you add the Bot 1 Autosampler to your MFI 5000 Series system, you’ve got the automated go-to method of choice for particle analysis today. Together, this combination lets you quickly screen for any changes in levels of particle contaminants like protein aggregates and silicone oil in your biopharmaceutical formulation. Highly concentrated protein solutions can be a little trickier to analyze with other…

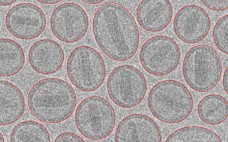

Objective characterization of liposomal drug delivery platforms: Using cryoTEM and designated image analysis software

Quality-critical attributes particular to liposome drug products include physicochemical properties such as particle size distribution and morphology, e.g. their overall shape. Such properties will influence the biological activity and bio-distribution of liposomal-based drug and gene delivery platforms. Analytical techniques that provide objective and reliable information on liposome particle characteristics can thus help to improve product development processes and shorten the time to securing their final quality. Cryo-transmission electron microscopy (cryoTEM) combined with image analysis using proprietary Vironova Analyzing Software (VAS)…

Understanding Single-Pass Tangential Flow Filtration and the New Era of Bioprocessing

Learn how single-pass tangential flow filtration (SPTFF) technology is revolutionizing current and future bioprocessing platforms with its implementations in biotech, vaccine and plasma industries. Adopting SPTFF at process development (PD), pilot, clinical and commercial manufacturing scales has major advantages over conventional approaches. Key benefits include flexible manufacturing, reduced processing volumes, high product recoveries and increased yield, as well as major savings in capital expenditures. SPTFF also enables disposable and/or single-use technology utilization.

CHO Cell Cultivation in the Allegro™ XRS 20 Bioreactor System with Working Volumes from 2 to 25 L

The Allegro™ XRS 20 bioreactor system is a single-use bioreactor technology designed for applications ranging from general life sciences research to seed train operations, and as a final stage reactor for small scale commercial production. In practice, many installed systems have been implemented into seed train and small scale GMP production operations, where operational simplicity and consistent results are key benefits for industrial users. In the application note summarized here, we report efforts to enhance the capabilities of the…

Pall SoloHill® Animal Protein-Free Microcarriers for Dengue Virus Production

Pall Life Sciences offers a variety of regulatory-friendly animal protein-free (APF) SoloHill® microcarriers that can be quickly and easily optimized for use in vaccine production platforms. Our application note describes dengue virus production in Vero, optimizing cell culture seeding densities and microcarrier working concentrations for efficient cell attachment and growth in two different cell culture media platforms: a traditional serum supplemented formulation and a commercially available serum-free formulation (SFM). Overall, the results of this study demonstrates that Pall APF microcarriers…

Objective Characterization Data on Drug and Gene Delivery Platforms

This webcast features: Dr. Josefina Nilsson, Head of Vironova Services, as well as her colleagues, Gustaf Kylberg and Mathieu Colomb-Delsuc. Advanced analytics that provide objective and reliable data can help to improve processes and shorten development time of drug and gene delivery platforms. The use of electron microscopy (EM) imaging combined with analysis using the proprietary Vironova Analyzing Software (VAS) enables semi-automated particle detection and classification. Statistically significant results are obtained in a time and cost effective manner. Typical data…

Taking Advantage of High Capacity Protein A: An Economic Comparison of the Resin Cost Per Gram of Antibody Produced

With pressures mounting to reduce production costs at many companies, and protein A being the most expensive resin used in mAb purification, the use of a high capacity protein A resin can significantly impact the overall cost of doing business. This report details how using a high capacity protein A resin will reduce production costs, on a per-gram produced basis, for companies that implement its use in their chromatography platform.

Future Immunoassay Approaches in Modern Bioprocess Development

Modern bioprocess development requires accurate, high throughput analytical methods to match scaled-down, high-throughput screening, the application of DoE, and science-based decision making consistent with QbD. Gyrolab™ systems and Gyros’ immunoassay kits constitute a proven platform that supports these needs today and has the capability to meet future challenges. The assay principle uses high-capacity, flow-through affinity columns embedded within a CD. Centrifugal force, capillary action and hydrophobic barriers are exploited during parallel processing of up to 112 samples on each CD.…

Decreasing Cost of Clinical Trials Through the Use of Two Novel Protein A Resins

Tackling the High Cost of Protein A in Early Clinical Phases The cost of Protein A resins is very high, commonly 5-10 times higher compared to standard chromatography resins. One way to address this issue is to use a less expensive Protein A resin during early clinical trials, where the risk of failure is higher and fewer cycles are run, and subsequently switch to a resin designed for manufacturing if the product makes it to PIII and beyond. The higher…