This webcast features: Antonia Guerra, Global Digital and Data Science Leader, Field & Safety Instruments, Thermo Fisher Scientific™ This webinar presents the new virtual companion to the Thermo Scientific™ TruScan™ RM Handheld Raman Analyzer, the Virtual TruScan™ RM (VTR) App, which creates efficiencies in material identity verification. This first-of-its-kind digital tool puts the TruScan RM’s decision algorithm in the cloud and allows for method validation and spectral re-processing without the need for a physical sample. With the VTR app, wait…

Webinars

Best Practices for Aseptic Sampling from Stainless Process Equipment

This webcast features: Bobbi Allen, Technical Expert, Aseptic Sampling, Sartorius Stedim Biotech Aseptic sampling from stainless process equipment is a regulatory requirement and can be accomplished in many ways. How samples are removed from the process stream and the containers you collect them into can have an impact not only on the integrity of the process but the accuracy and repeatability of the tests you are performing. Emerging technologies can streamline sample taking, minimize risk to process, and improve the…

A CDMO’s Perspective on the Development of Bioprocesses for Clinical Manufacturing Success

This webcast features: Nigel Shipston, Director, Program Design, FUJIFILM Diosynth Biotechnologies A strategy for the development and scale of bioprocesses should be assessed at the earliest of stages. There are different challenges depending on the molecule and expression system. This webinar is designed to address some of the areas of consideration for successful development of bioprocesses for biologics and gene therapies. At the end of this webinar, you will be able to do a self-assessment to answer some critical questions:…

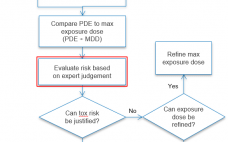

Case Study in Conducting Chemical Safety Assessments for Single- and Multi-Use Manufacturing Components

This webcast features: Dr. Sherry Parker, Senior Director, Regulatory Toxicology and Technical Services, WuXi AppTec Extractable and leachable studies of single- and multi-use manufacturing components should be followed up with a chemical safety assessment to understand the chemical risks based on the toxicity of the chemical, the dose and the exposure duration of the drug product, and the patient population for its intended use. This case study will illustrate considerations when conducting a chemical safety assessment, the pitfalls of having…

Closed, Single-Use TFF Assembly Makes Performance-Leading TangenX Cassette Technologies Even Easier to Use

This webcast features: Michael LaBreck, Global Bioprocess Sales Specialist, TangenX™ TFF Products, Repligen Corporation SIUS-Gamma TFF cassettes incorporate the performance-leading TangenX™ TFF membrane and cassette manufacturing technologies into a closed, gamma-irradiated, single-use assembly. Genderless, aseptic connections easily integrate into your current UF/DF flow path, and a library of 64 MWCO and surface area configurations provide rich process options. The closed format, leading TFF performance (flux, selectivity, reproducibility) of the TangenX membrane and manufacturing innovations that enabled the first single-use by…

Asahi Kasei Bioprocess’ Planova SU-VFC: Realizing Single-Use Technology in Virus Filtration

This webcast features: Brian Crawford, Director of Operations, Asahi Kasei Bioprocess America, Inc. By eliminating the need for clean-in-place, reducing demands on quality control, and optimizing product changeover times, single-use systems offer great benefit at pilot, clinical, and commercial production scales. The new Planova™ Single-Use Virus Filtration Controller (SU-VFC) from Asahi Kasei Bioprocess America, Inc. offers the hallmark consistency of Planova™ filters in a compact, fully automated single-use form factor with full 21 CFR Part 11 compliance for greater efficiency…

Discover Capsugel Dry-Powder Inhalation Capsule Portfolio

This webcast features: Claire Tardy, PhD, Research & Development Manager, Capsule Delivery Solutions, Lonza Pharma & Biotech Dry-powder inhalation (DPI) is a major drug delivery technology for the treatment of respiratory diseases and increasingly for systemic drug delivery. Providing a uniform dose in a portable, easy-to-use system, capsule-based DPI is a simple and cost-effective way to deliver medication via the pulmonary route. Within dry-powder inhalation application fields, Lonza offers the Capsugel® Zephyr™ Dry-Powder Inhalation portfolio: high-quality capsule solutions based on…

Aseptic Filling for Gene Therapies and Next-Generation Biologics Within Closed Robotic Workcells

This webcast features: Thomas Page, PhD, Vice President, Engineering and Asset Development, FUJIFILM Diosynth Biotechnologies Fujifilm Diosynth Biotechnologies (FDB) sought to “close the loop” by keeping all upstream and downstream aseptic processing operations within closed systems. The missing part was downstream, where FDB implemented a closed robotic filling workcell for manufacturing gene therapies. Workcells solve long-standing problems with sterility assurance, containment, and process control in aseptic filling. The knowledge developed by FDB during its implementation and early use of a…

Accelerating Timelines by Integrating Cell Line Development and Manufacturing Programs

This webcast features: Nicole Wakes, Group Leader, Cell Line Development, Abzena The start of cell line development represents a significant milestone for biologics innovators: It’s a commitment to a specific molecule and the start of the journey towards IND. By using the latest technologies such as automated multiple microscale bioreactors and high-throughput analytics, it is possible to interrogate clones more closely to determine productivity, manufacturability, and performance at scale and at an early stage. In addition, the data generated can…

Implementation of Single-Use Fermentation Technology

This webcast features: Andrew Lowell, Associate Director, Upstream Process Development, KBI Biopharma, Inc. KBI Biopharma, Inc. has implemented single-use fermentation (SUF) systems that have allowed greater throughput and efficiency in the laboratory, leading to accelerated project timelines to good manufacturing practice (GMP) production. The single-use fermentation systems address those programs with relatively small material needs while decreasing validation requirements and increasing operational efficiencies. Coupling process design with the SUF equipment capabilities has enabled processes capable of high cell densities and…