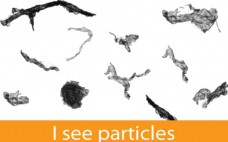

Micro-flow imaging (MFI) is a sensitive, simple and automated method for the analysis of sub-visible particles and translucent protein aggregates that provides particle size, count and morphology. Because it quantifies particle shape, this technology can discriminate groups of particles from each other, and evaluate how these groups change over time. In this article, we provide an overview of how biopharma is using MFI to characterize and monitor their protein formulations in new and emerging applications.

BPI White Papers

POROS® CaptureSelect™ Affinity Columns for Rapid, Small-Scale Purification and Sample Preparation of Recombinant Proteins

This application note describes a model system in which Enbrel® protein, a fusion protein consisting of TNF receptor and IgG1 Fc, is purified from a dilute sample matrix for further analytical characterization. The resulting purified protein was subjected to N-linked glycan structural analysis by mass spectrometry (MS) and its aggregation state was assessed by analytical ultracentrifugation (AUC). This data set serves as a model to demonstrate the capability of the POROS® CaptureSelect™ product line for the affinity purification of biomolecules…

Control Over Your Microbial Identification Using the Gold-Standard Genotypic Method

Eliminate your outsourcing needs! Gain visibility and control. Learn how the next-generation, high-throughput MicroSEQ® system delivers right-first-time accuracy and give you complete control over microbial identification, by owning the system, the process and data analysis.

Charge Heterogeneity Analysis in 10 Minutes

Platform methods, high resolution and ease of use have made the iCE system the gold standard for protein charge heterogeneity characterization for biopharmaceuticals. At 15-18 minutes per sample, iCE methods are already fast and simple but now they are even better. In this white paper we describe a high throughput 10 minute charge heterogeneity analysis method and performance improvements that provide automated analysis of 100 samples at a time.

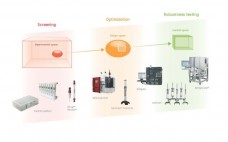

How to Achieve Greater Efficiency in Biopharmaceutical Process Development

Read about GE Healthcare Life Sciences’ support from efficient process development to production through products, consulting services as well as specific, individual collaborations. “Our aim is to help bioprocessing teams to map the optimal plan to transform an idea into results, with greater flexibility and confidence, reducing time and costs along the way. Our global team of bioprocessing experts will support you in the optimization and troubleshooting of existing unit operations or in the design of efficient and cost-effective processes…

Scale-Up of Adherent Vero Cells Grown on Cytodex™ Microcarriers Using ReadyToProcess Equipment

In cell culture-based vaccine production, scale-up of adherent cells is challenging. This study shows a process for scaling up adherent Vero cells from static cell factories to influenza production at 50 L scale using WAVE Bioreactor™ systems and ReadyToProcess singleuse equipment. Vero cells were grown to high cell density on Cytodex microcarriers in 10 L working volume. The cells were detached with trypsin and used to seed a 50 L production culture with the same microcarrier concentration. The cells were allowed to reattach and grow on the new microcarriers in a larger Cellbag™ bioreactor chamber. Cells were subsequently infected with influenza virus. The results show a repeatable scaleup procedure.

How cells grow, the discovery of the insulin like growth factors

Find out how a misconception lead to the discovery of grow factors, the insulin-like effects (involving several Nobel laureate), and understand why the surprising side effect of insulin can be employed as a substitute for the natural growth factor as nearly universal growth factor in cell culture.

Purification of Oligonucleotides on TOYOPEARL GigaCap® Q-650S

TOYOPEARL GigaCap Q-650S is capable of delivering oligonucleotides of comparable purity and slightly higher process yields under the same operating conditions to those seen with resins requiring higher operating pressures. This capability allows chromatographers to purify oligonucleotides without the added expense of purchasing high pressure manufacturing equipment.

Overview of a Scale-Up of a Cell-Based Influenza Virus Production Process

The aim of this white paper is to demonstrate how GE Healthcare Life Sciences single-use products can be applied in the field of vaccine manufacturing. A brief discussion around modern vaccine processes is followed by a case study showing the scale-up of upstream and downstream processes for the production of a cell based live attenuated influenza virus using single-use ReadyToProcess technology. Single-use equipment enables quick changeover between products, minimizes risk for cross-contamination between batches, and reduces the need for cleaning and validation operations.

Are You Into Biosimilars?

Learn about GE Healthcare Life Sciences’ aim to help bioprocessing teams map out the optimal plan to transform a biosimilars project idea into result, with greater flexibility and confidence and with reduced time and cost.