Stakeholders across the supply chain stress that quality of starting material will be key to the success of cell and gene therapies. This is a topic that has created issues in the past, is puzzling the industry presently, and is likely to cause more problems going forward. This topic was front and center at the 2019 Phacilitate Leaders World and World Stem Cell Summit in Miami FL, with presentations focusing on supply chain solutions to address these complex challenges; cell…

Supply Chain

The Role of Single-Use Polymeric Solutions in Enabling Cell and Gene Therapy Production – Part 3: Best Practices for Supplier Selection, Qualification, and Validation to Ensure Supply Chain Security

Bio-Process Systems Alliance (BPSA) was formed in 2005 as an industry-led international industry association dedicated to encouraging and accelerating the adoption of single-use manufacturing technologies used in the production of biopharmaceuticals and vaccines. Corporate members include plastic equipment suppliers, service providers, and users in the biopharmaceutical industry who share this mission. A key focus of BPSA’s core activities is to educate its members and others through sharing of information and development of best practice guides that help suppliers, users, and…

Going Beyond the Simple Customer–Supplier Relationship: Ensuring a High-Quality Supply Chain Through Transparent Partnerships

Operating a successful global supply chain to deliver single-use systems (SUS) for utilization in the biopharmaceutical industry is complex. In his insightful article, Claudio Catallo, Head of Global Supply Chain Management FMT at Sartorius Stedim Biotech, details the company’s intelligent approach to supply chain management and the models it uses. He also explains how expert teams and integration of digitalization across many sales, manufacturing, and distribution sites maintain the operational excellence required to support supply and demand in an ever-changing…

Introduction: The Ins and Outs of Market Demand

From transport and holding of bulk drug substance to shipping, warehousing, tracking, and distribution of final packaged drug products, biopharmaceutical supply chain logistics can be described as an industry in itself. And that’s just one side of the story. Even though much of the work of establishing and maintaining supply chains might happen outside the manufacturing environment, all organizations that develop processes and final products depend on having the raw materials and available components and resources to do their work.…

Standardizing Human MSCs As Critical Raw Materials in Cell Therapy Products: Streamlining Clinical Translation

Advancements in cell therapy, biofabrication, and synthetic biology have driven the growth of the global regenerative medicine (RegenMed) industry in the past decade. The industry has developed innovative treatment options for patients with otherwise unmet medical needs (1). Human or animal cells or tissues are used as critical raw materials in cell therapy products that can replace, regenerate, or augment patients’ diseased, dysfunctional, or injured cells, tissues, or organs. These cells or tissues can be unmanipulated, or their biological characteristics…

Spray Freeze-Drying Technology: Enabling Flexibility of Supply Chain and Drug-Product Presentation for Biologics

Biopharmaceutical drug substances (DSs) and drug products (DPs) commonly are stored frozen or refrigerated to maintain stability through long-term storage, handling, and transportation (1). Temperature excursions during storage and transport can affect product quality adversely by compromising the safety and efficacy of these molecules. Thus, cold-chain management throughout the shelf life of these products is a critical component in the supply chain strategy for them. The cost and complexity of cold-chain management is a well-known challenge faced by the biopharmaceutical…

Rapid, Reliable Response to Biologic Drug Substance and Drug-Product Supply Challenges

Scott Battist, vice president, general manager, and site head for the drug substance plant, Emergent Bio BJ Hull, vice president, general manager, and site head for the drug product plant, Emergent Bio Willfredo Mateo, director of MS&T for the Camden fill–finish plant, Emergent Bio Emergent Bio started by producing treatments for an anthrax emergency. Traditionally, this has been a biodefense company with contracts from the US government. The company is focused on providing specialty products for civilians and military members…

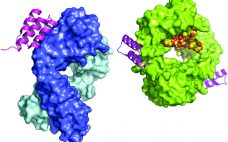

Dual Sourcing of Protein A Resin to Mitigate Supply Chain Risk: A Comparative Study to Determine Equivalence

Protein A affinity chromatography is a well-established technology that is used extensively for large-scale purification of monoclonal antibodies (MAbs). With this mode of chromatography, very high product purity can be achieved in a single, relatively simple unit operation. A solution containing the target protein of interest is applied to a liquid-chromatography column at near-neutral pH, and one or more wash steps follow to lower product- and process-related impurities (1). Product is eluted through application of a low-pH buffer. Finally, the…

Sourcing Clinical-Grade Human Tissue: Considerations for Supporting Cell Therapy Development and Production

The rapidly developing global cell therapy market poses numerous industry challenges for drug development, process scalability, commercialization, and patient safety. The processes of procuring donated human tissue for clinical applications are fraught with many technical, ethical, and legal issues. Allogeneic cell therapies involving primary cell types such as bone marrow mesenchymal stromal/stem cells (BM-MSCs), hematopoietic stem and progenitor cells (HSPCs), and T and natural killer (NK) cells for immunotherapy applications are especially challenging because of the vigorous process of screening…

BioPhorum Operations Group Technology Roadmapping, Part 2: Efficiency, Modularity, and Flexibility As Hallmarks for Future Key Technologies

For a complex biopharmaceutical industry, setting out to forecast future technologies must involve considering how such technologies will be used. In the first article (1), I discussed why there was a need to develop a technology roadmap for the biopharmaceutical industry and the trends shaping its future: namely, the introduction of new product classes, the continued growth of the biopharmaceutical market, pressure to reduce costs, and uncertainty in approval and sales of new products. Herein I discuss the technology roadmap’s…