Because they occur after two highly engineering, and science-driven phases of biomanufacturing – expression and purification – biopharmaceutical fill and finish processes have not received the respect traditionally that they deserve. Yet of all competencies associated with bringing biopharmaceuticals to market, fill and finish arguably are the most specialized. This eBook reports on the technical and operating challenges impacting the latest formulations and devices including: outsourcing, contamination, standardization (pre-filled syringes), lyophilization, and serialization. Get informed on the current state-of-the-art technologies…

Fill/Finish

Single-Use Fill and Finish: An Interview with NNE Pharmaplan

I talked with NNE Pharmaplan’s Kim Vincent Andersen (single-use technology and biotechnology specialist) and Niels Guldager (global technology partner in biotech) to discuss their experiences with client facilities that incorporate significant elements of single-use technology. In particular, they highlighted a recent project for Novo Nordisk involving a large-scale greenfield filling and inspection facility in Hillerød, Denmark. Find more detailed information about the project online at https://goo.gl/yp4LQh. And you can watch a video about it here: https://youtu.be/czwwgdt3CxI. A Case Study You…

Response to the Publication of USP ‹1207›

The BioPhorum Operation Group’s (BPOG’s) Container Closure Integrity Testing (CCIT) workstream would like to congratulate the United States Pharmacopeia’s committee for its latest revision to USP chapter <1207> Package Integrity Evaluation: Sterile Products. Generally, we believe it provides a comprehensive overview of the available methods for container–closure testing and outlines many important elements for consideration in establishing a successful CCIT strategy. We first responded to the USP <1207> draft when it was released for comment in 2014. And from our…

Elastomer Stoppers: Working Toward Adopting an Industry-Wide User Requirements Specification for Particulate Levels

Two years ago, the companies involved in the BioPhorum Operations Group (BPOG) fill–finish community agreed that the quality of elastomer stoppers for vials was causing problems for biopharmaceutical manufacturers. So they deemed it to be a priority for the group. The problem is particularly pronounced for vial stoppers used in legacy products, which may have been on the market for several years. Many such medicines remain valuable for large patient populations. The stoppers used on legacy medicines are manufactured using…

A Single-Use, Clinical-Scale Filling System: From Design to Delivery

Single-use components have been successfully incorporated into many unit operations for both upstream and downstream processing, from laboratory scale to commercial manufacturing. The development of single-use filling needles has created an opportunity to introduce fully disposable systems into final formulation and filling of drug products (1). One major challenge in replacing a cleanable filling line containing stainless steel needles is to ensure that an alternative system can satisfy all critical performance parameters established for an existing process. In 2012, Merck…

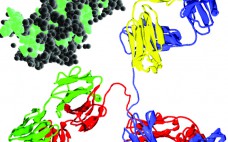

Critical Factors for Fill–Finish Manufacturing of Biologics

Over recent decades, protein-based therapeutics have emerged as key drivers of growth in the pharmaceutical industry. Drug development pipelines have filled with biologics, and a handful of monoclonal antibody (MAb) products have become some of the best-selling drugs around the world. Production of biotherapeutics is often challenging because of the inherent instability of these large, complex molecules. Their fragile nature has forced manufacturers to change how bulk drug substances (BDSs) are handled and final drug product is formulated, sterile filtered,…

Special Report on Assays, Test Methods, and Comparability The CMC Strategy Forum Series, Part 4, The Roles of Bioactivity Assays in Lot Release and Stability Testing

A January 2007 CMC Strategy Forum on the roles of bioactivity assays in lot release and stability testing was held in Washington, DC (1). Its purpose was to promote an understanding of the design and utility of bioassays throughout product development and to delineate the conditions under which surrogate assays could be used to determine product potency. Topics of discussion included appropriate assay selection at each stage of product development, the potential use of binding assays for potency testing, and…

Compatibility Assessment of a Model Monoclonal Antibody Formulation in Glass and Blow–Fill–Seal Plastic Vials

Blow–fill–seal (BFS) technology has been recognized by the industry as an advanced aseptic solution (1–3). Catalent Pharma Solutions has been commercially supplying sterile BFS products to the pharmaceutical industry for decades, primarily in the respiratory and topical ophthalmic markets. Such product formulations range from simple solutions to emulsions with drug substances from classical small molecules to large complex proteins such as biologics. The company also has optimized BFS processes and its Advasept plastic container system for the manufacture of sterile…

Formulation/Fill–Finish: BPI Theater @ BIO 2015

Matt Feldman (senior manager of strategic communications, Aeras) 10:00–10:25 am Vaccines, Global Health, and the Future of Fighting Tuberculosis Aeras is a nonprofit biotechnology company located in Rockville, MD, with other locations in Beijing, China, and in Cape Town, South Africa. Its mission is to advance tuberculosis (TB) vaccines worldwide. The fully integrated biotech company has in-house capabilities in finance, portfolio management, and manufacturing, taking products from preclinical through phase 2b clinical trials. Aeras is governed by a board of…

New Approaches to Fill and Finish: A BPI Theater Roundtable at Interphex 2015

On Wednesday, 22 April 2015, Susan Dexter (principal consultant at Latham BioPharm Group) chaired a midday roundtable titled, “Fill and Finish Manufacturing Strategies: Better or Just New?” She brought together three industry experts to provide mixed perspectives: Joseph Figlio (senior project officer for the manufacturing facilities and engineering division of the Biomedical Advanced Research and Development Authority, BARDA, in the US Department of Health and Human Services Office of the Assistant Secretary for Preparedness and Response) Victor Lee (vice president…