As viral vectors continue to push gene therapy innovations closer to market, many researchers are setting their sights on optimizing transfection, the process of delivering corrective genetic material into cells. It’s not just a question of how to transfect them, but also how to do so efficiently and at high volumes. Approaches that work for one cell line might not perform well for others, and transfection protocols can have different implications for scalability and cost during production for clinical trials.…

Cell/Gene Therapies

Focusing on the Patient Journey Can Increase Access to Lifesaving Therapies

Cell and gene therapies (CGTs) are positioned currently as last-chance, “miracle” cures for patients who have severe illnesses. Such promises require innovation. Despite the cutting-edge science and significant investment that goes into CGT development, fundamental challenges remain, including patient access. The highly personalized nature of autologous-therapy development presents myriad logistical, financial, and manufacturing challenges to ensuring global access to treatment. Understanding a patient’s journey to treatment is vitally important to achieving that goal. Barriers to Cell and Gene Therapy Access…

Recombinant Proteins for Cell and Gene Therapy Research: A Conversation with Shenandoah Biotechnology

Recombinant proteins such as growth factors and cytokines are essential for cell therapy, gene therapy and regenerative medicine research, development and manufacturing. These proteins are critical in the production of desired cell types and subsequent differentiation of cells, to deliver the desired effect. Founded 15 years ago, Shenandoah Biotechnology applies a proprietary method of folding and purifying recombinant proteins from both bacterial and mammalian systems to enable cost-effective, large-scale production of Cell Therapy Grade proteins to support these groundbreaking treatments.…

No More Sleepwalking: New Mindsets for Manufacturing Cell and Gene Therapies at Commercial Scale

Cell and gene therapies (CGTs) offer potential cures to some of the most challenging illnesses of our time. The number of such therapies approved for market is set to surge in the next 10 years (1). Yet current manufacturing approaches are not fit for purpose. Biomanufacturing must adapt to prevent the industry from unintentionally sleepwalking into causing harm to patients. Some urgently needed changes could come with learning about the mindset of the medical-devices industry. Background and Current State After…

eBook: CAR-T Cell Therapy — Mitigating Clinical and Bioprocess Limitations

Developers of chimeric antigen receptor (CAR) T-cell therapies are working in a state of tempered optimism. As of September 2021, the US Food and Drug Administration has approved only five such products, two coming this year. Now that those approved products have demonstrated the viability of CAR-based immunotherapies, drug developers are trying to address significant limitations that have come to light with increases in available clinical data and bioprocess knowledge. One shortcoming concerns therapeutic efficacy. Blood cancer patients who have…

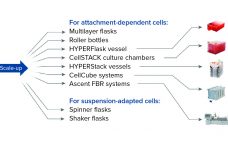

Strategizing Scale-Up and Scale-Out for Cell Therapy Production

When considering strategies for expanding the number of cells being grown to support cell therapy development, companies often focus on decisions regarding scale-up and scale-out: increasing capacity either by using larger vessels to increase production volume or by implementing more units of the same vessel, respectively. Complete workflows often involve both. Figure 1 shows an example of scaling out from one to multiple cell culture flasks of the same dimension before transitioning to a larger format. Scale-out can be straightforward…

Ask the Expert: Streamlining Mesenchymal Stem Cell Production — From Expansion Through Removal of Cryoprotectant

The number of cell therapy product candidates based on mesenchymal stem cells (MSCs) has grown steadily since their clinical debut in 1995. As of June 2020, clinical investigators were evaluating more than 1,100 such therapies. Scaling up MSC production remains challenging, however. On 31 May 2021, Hilary Sherman (senior scientist at Corning Life Sciences) presented an “Ask the Expert” webinar describing her company’s efforts to facilitate MSC workflows. Sherman’s Presentation Easing Expansion: MSCs have strong differentiation capability and can be…

Corning X-WASH System: DMSO Reduction of Cryopreserved Human Mesenchymal Stem Cells

Cryopreservation is a necessary part of workflows for both autologous and allogeneic therapies. The ability to cryopreserve cells for cell therapy increases the range of administration, shelf life, and time for safety testing. Cryoprotectants such as dimethyl sulphoxide (DMSO) often are added to freezing media to increase post-thaw cell survival. However, DMSO itself can be cytotoxic, so reducing its final concentration can be necessary. Below, I demonstrate how the Corning X-WASH system can reduce the amount of DMSO used in…

Accelerating the Development of Cell and Gene Therapies: From Discovery to Biomanufacture

Oxgene, a WuXi Advanced Therapies (WuXi ATU) company, provides cell and gene therapy pioneers around the world with technologies, automation platforms, and service solutions to advance their preclinical research and accelerate their timelines to good manufacturing practice (GMP) manufacturing. WuXi ATU, a global contract testing, development, and manufacturing organization (CTDMO), offers world-class, integrated GMP manufacturing and testing platforms to reduce time to market, while maintaining high titers, high levels of quality assurance, and full regulatory compliance. Together, our complete end-to-end…

Autologous CAR T Cell Manufacturing Using a Semiautomatic, Closed, Modular Workflow: Seamless Transition from Discovery to Clinical Manufacturing

Chimeric antigen receptor (CAR) T cell therapies have advanced rapidly in recent years, with a number of targets in clinical research and several US Food and Drug Administration (FDA)-approved products already on the market. There has been tremendous effort to make CAR T cells more effective, safe, and persistent when treating patients. On the manufacturing side, however, errors, lot-to-lot variation, and contamination can be associated with open processes and manual handling of CAR T cells. Cell isolation, gene editing, expansion,…