It is well recognized that the cost of Protein A resins is substantial. If a product makes it to marketing approval and manufacturing the high cost is amortized over a large number of purification cycles then the contribution to cost of goods is acceptable. However, a high percentage of clinical projects will fail and the Protein A resin will only be used for a small number of cycles. One way to address this issue is to use a less expensive…

Downstream Processing

Reducing Clinical-Phase Manufacturing Costs: Collaborating for Savings without Compromising Quality or Performance

In downstream purification of monoclonal antibodies (MAbs), the single greatest contributor to manufacturing costs is the expensive capture step typically based on protein A affinity chromatography. Almost since its introduction to bioprocessing, efforts have been made to reduce the cost of this step. Several alternative ligands have been promulgated as potential replacements for protein A, but they have proven difficult to adopt and scale up. Supplier companies have pushed for increases in capacity and economics, but those are always accompanied…

Membrane-Based Clarification of Polysaccharide Vaccines

Polysaccharide vaccines are essential for protection against infectious diseases, which remain an alarming cause of mortality. The first glycoconjugate vaccine for use in humans — a Haemophilus influenzae type b (Hib) conjugate — was licensed in the United States in 1987. This vaccine successfully reduced the incidence of invasive Hib disease in childhood and led to the further development of conjugate vaccines designed to prevent infection by other encapsulated bacteria (1). Polysaccharides are relatively complex carbohydrates made up of many…

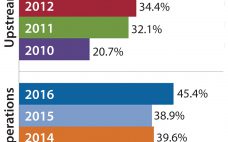

Outsourcing of Buffer Preparation Activity Is Increasing

The major fluid products used in bioprocessing — culture media and buffers — are classically prepared in-house by rehydrating (dissolving and mixing) powders purchased from suppliers. Most bioprocessing facilities consider in-house preparation of these fluids to be a core bioprocessing task. However, some companies are outsourcing the work either by purchasing preprepared materials from vendors or hiring contract manufacturing organizations (CMOs) to prepare them. Buffer fluid preparation is one area of downstream production operations that are seeing an increase in…

Special Report: A Strategy for Cost-Effective Capture Using Agarose-Based Protein A Resins

It is well recognized that the cost of Protein A resins is substantial. If a developmental monoclonal antibody (MAb) makes it to marketing approval and manufacturing, the high cost of purification using a Protein A resin is amortized over a large number of purification cycles, and the contribution to cost of goods is reduced to acceptable levels. However, a high percentage of clinical projects will fail, and the Protein A resin will be used only for a small number of…

Innovative Downstream Purification Solutions for Viral Vectors: Enabling Platform Approaches to Advance Gene Therapies

Over the past decade, gene therapy applications and their importance in the biopharmaceutical industry have been increasing. Gene therapies promise versatile treatment options that could revolutionize and transform medicine. As treatment modalities, they offer the possibility of long-term and potentially curative benefits to patients with genetic or acquired diseases. Gene therapies are designed to treat disease by delivering genetic material that encodes a protein with a therapeutic effect into a patient’s cells. It can be used to replace a missing…

Emerging Technology Trends in Biologics Development: A Contract Development and Manufacturing Perspective

For a contract development and manufacturing organization (CDMO), process development and manufacturing of recombinant proteins must be linked because of tight timelines driven by client expectations. Those are in turn driven by a need for rapid progression to clinical testing. Early in process development, the choice of raw materials needs to reflect existing supply chain and manufacturing infrastructure, but remain suitable for scaling up to meet future needs. One approach is to establish platform processes for a class of molecules…

Selective and Flexible Chromatography Media: Improving Biopharmaceutical Operational Efficiencies

Continuing development in protein and peptide engineering have produced a broad range of new biological products with improved therapeutic and diagnostic potential. In the development pipeline, more than 900 biologic products target more than 100 diseases (1). Increased manufacturing complexities caused by closely related impurities and requirements to improve process efficiencies and reduce operating costs highlight the need for new approaches in protein purification. Platform-based chromatographic approaches have been successfully applied in separating and purifying monoclonal antibody (MAb) products. But…

Viral Clearance in Antibody Purification Using Tentacle Ion Exchangers

Manufacturers strive toward cost-effective purification of target molecules and a high level of confidence that their biologics are safe and not compromised by the presence of endogenous retrovirus-like particles or adventitious viruses (1). Reliable reduction of viral particles throughout downstream purification processes must be ensured through different techniques such as chemical treatment, filtration, and chromatography. Common monoclonal antibody (MAb) purification schemes use both cation- and anion-exchange chromatography steps (CEX, AEX). Although CEX (to remove product- and process-related impurities) is not…

Preparing for Continuous Bioprocessing: An Interview with Pall Corporation’s Chief Technology Officer Martin Smith

Martin Smith, PhD, has been with Pall for about nine years and assumed the role of chief technology officer at Pall about 18 months ago. He spoke with Cynthia Challener, PhD, about Pall’s biopharmaceutical business unit and how the company is positioning its technology suite for a continuous process paradigm. Smith: There is no doubt in our minds that we see movement toward continuous bioprocessing. When you look across an array of different industries, the move to continuous or parallel…