Quality risk management (QRM) is a systematic process for assessment, control, communication, and review of risks to the quality of a pharmaceutical product across its lifecycle. Although QRM is not new (1), the regulatory focus on QRM will increase with the arrival of the European Medicines Agency’s (EMA’s) Annex 1 (2), which was reviewed by the US Food and Drug Administration (FDA), the World Health Organization (WHO), and the Pharmaceutical Inspection Convention Scheme (PIC/S). Integrity testing of sterilizing-grade filters is…

Risk Management

Unraveling the Complexities of Technology Transfer

In the biopharmaceutical industry, technology transfer refers to transfer of any process, together with its documentation and professional expertise, between development and manufacture or between manufacturing sites (1). This operation is common in the biopharmaceutical industry for a number of structural reasons. They include the dichotomy between small, innovation-based drug companies and large ones able to conduct late-phase clinical development and endowed with manufacturing capacity; the high capital cost of biopharmaceutical plants, which makes contract manufacturing attractive; and the need…

Life-Science Lawsuits: Learning from the Ordeal

Life-science companies often are cast into the role of the “canary in the coal mine” — the first parties to be targeted and hit by lawsuits. Such companies depend on discovery, trial and error, and ultimately efficacy. None of that is a sure bet. At the same time, life-science companies are raising funds constantly to finance their work. Investors and lenders seeing less-than-projected or even “expected” results might sue directors and officers for mismanagement, misrepresentation, or misleading financial statements. This…

A Response Plan for Viral Contamination in Bioproduction Facilities

The biopharmaceutical industry uses living biological systems as a platform for manufacturing of protein-based drugs, vaccines, and other therapies derived from or consisting of different cell types. On one hand, living systems are inherently susceptible to viral infection and may harbor endogenous viruses, so the potential for such contamination cannot be eliminated. On the other hand, the industry has an excellent patient-safety record. Viral safety is achieved through three fundamental measures: prevention (e.g., by selection), removal (by clearance and/or reduction),…

eBook: Joining Forces — Industry Collaborations Toward BioProcess Success

Companies in the biopharmaceutical industry increasingly are working together to solve the many challenges of product/process development and biomanufacturing. Suppliers seek end-user help in refining technologies; academics and small innovators attract the financing and business acumen of large companies; equal partners share in technological problem-solving; and sponsors engage the development expertise of contract research and manufacturing organizations. Other examples of biopharma industry collaborations abound, too. Citing critical examples from the September 2019 BioProcess International East Conference in Boston, MA, this…

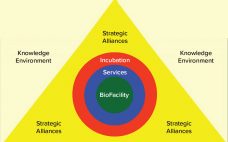

From Supplying Components to Providing Total Solutions: Overviewing Supplier Side Capabilities

Only a thin line now separates biopharmaceutical manufacturers and suppliers because the latter are increasingly becoming the process knowledge owners in the biopharmaceutical industry. As a result, suppliers are racing to become the most efficient “total solutions” provider. In the 1990s, leading players in the industry such as Pall, Millipore, and Sartorius all supplied membrane filters for upstream and, to some extent, downstream processes with their crossflow and final filtration offerings. Pharmacia (which became GE Healthcare) was the major force…

The First Quantitative Industry Assessment of Single-Use System (SUS) Reliability: Raising the Bar for BPSA’s Value to Industry

Over the past 24 months, the leadership of the Bio-Process Systems Alliance (BPSA) has initiated a pilot program to demonstrate the joint feasibility of collecting and sharing pertinent industry business data. We began with “quality-complaint data” centered on the premise that product complaints are tightly associated with product-quality defects in single-use systems (SUSs). This approach can be viewed as “risk assessment 101.” BPSA’s Representation of the Single-Use Industry BPSA is an industry organization primarily comprising drug manufacturers, single-use system suppliers,…

Risk Management of Biopharmaceutical Operations: End-to-End and Over Lifecycle

Biopharmaceutical manufacturing processes that were developed before the implementation of quality by design (QbD) typically use control strategies that are not founded on a formal understanding of criticality. Thus, manufacturers of “legacy” products lack the understanding of critical process parameters (CPPs) and critical quality attributes (CQAs). Introducing such elements to a legacy biologic drug product filing aligns fully with expectations described in the ICH Q12 guideline (e.g., increased process understanding and better risk mitigation strategies) (1). Here we discuss how…

Recommended Practices for Assuring Integrity of Single-Use Systems

The increasing uptake of single-use technologies (SUTs) in critical current good manufacturing practice (CGMP) processes and applications has made their integrity a critical quality attribute (CQA) for both suppliers and end users of such systems. Current regulations focus on final packaging, however, without taking into account the unique aspects of assemblies used in bioproduction. Ongoing initiatives include revision of PDA TR 27 (1) and creation of A STM workstreams (2, 3) to propose good practices for the integrity of single-use…

The Complete e-Book of Biosafety Testing

Expect the expected. But plan for the unexpected. If your Biosafety Development takes a nose dive, Eurofins Lancaster Laboratories’ team of regulatory experts and experienced scientists will help you land safely on two feet. Download The Complete e-Book of Biosafety Testing to learn more about our expertise in biologics raw materials, cell bank preparation, adventitious virus testing, viral clearance studies, next-generation sequencing, genetic stability testing, and more. This e-Book contains the following chapters: Mitigating Risk and Reducing Regulatory Scrutiny of…