You need the right data at the right time from your supplier to make important production and supply chain decisions to achieve your Biopharma Manufacturing goals. Now you have the eMERGE™ Program, our standard platform for the exchange of electronic data. It provides key raw material data, electronically, for every shipment, so you can start making informed decisions right away.

BPI White Papers

Vero Cell-based Vaccine Production: Cell lines, Media and Bioreactor Options

The recent Covid-19 pandemic introduced new challenges for the vaccine industry, it has also brought in new innovations in vaccine development including DNA/RNA based vaccines. The pandemic also increased the demand for well-established cell-based vaccine production technologies. The article reviews strategies for optimizing Vero cell-based vaccine production using rabies and influenza as examples. The Vero cell line is one of the most satisfactory vaccine production hosts based on its infectability, stability and well-documented performance in quality and quantity of viral…

Improving the Bioavailability of Challenging APIs using Hot Melt Extrusion with Polyvinyl Alcohol

New molecular entities (NMEs) are becoming larger, more crystalline and more lipophilic and, as a result, less soluble. While approximately 40% of active pharmaceutical ingredients (APIs) currently on the market show poor solubility, it is estimated that between 60 and 90% of compounds in development have solubility challenges.1,2 For an oral formulation, API solubility and permeability are critical factors for absorption in the gastrointestinal tract. As a result of this, solubility-enhancing formulation techniques have become an area of focus for…

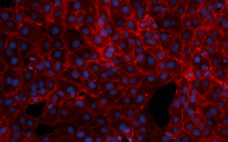

Evaluating Current Manufacturing Platforms for Viral Vector Production to Enable Gene Therapy Products

The rapidly growing interest in gene therapy has led to the need for more cost-effective and scalable viral vector manufacturing platforms to deliver these therapies. Adeno-associated virus (AAV) has become the vector of choice as it stands out for its safety profile since infection with the vector is not pathogenic. Also, AAV cannot replicate on its own and is not directly integrated into the host genome. Realizing the full potential of viral vector-based therapies requires a successful manufacturing platform for…

What Technologies Should You Apply to Your Vaccine-Specific Process?

Vaccines have been protecting against disease since the late 1700s. They function by triggering the immune system to generate short-term and long-term responses. Because there are many pathogens, there are also many vaccines. They can be classified by antigen character, but the manufacturing flows used to produce them are relatively similar. Read now our Vaccine Bioprocessing Handbook to learn more on similarities and differences on Vaccine processes for: viral vaccines, Virus-Like Particle (VLP) Vaccines, Polysaccharide Conjugated Vaccines, Viral Vector Vaccines…

Early Selection of Optimal Clones Made Easy: A New, High-Throughput, All-in-One Solution for Mannose Glycans Screening and Assessment of Critical Quality Attributes

Glycosylation is a critical quality attribute (CQA) and imparts properties such as stability, folding, solubility, cell-cell interaction and adhesion to proteins. Antibody glycosylation for example is critical due to the role carbohydrates play in modulating effector functions which affect safety and efficacy of therapeutic antibodies. The NEW Octet® GlyM Kit is designed to provide cell line development and upstream bioprocessing Octet® users with a ready to use kit for the rapid screening of % mannose content of purified and cell…

Advantages of Spray-Dried Mannitol in Roll Compaction Processes

Granulation steps as wet granulation are applied before the final step of tableting in order to achieve content uniformity, flowability and compressibility. Wet granulation applies water and therefore needs a drying step. To omit this for reasons of cost and API stability dry granulation or roller compaction is a compromise to achieve the desired content uniformity without having water involved and a subsequent drying step. Studies available in literature mostly focus on the use of MCC and lactose in this…

Is Fiber-Based Protein A Chromatography the Missing Piece in Single-Use mAb Purification?

Protein A chromatography resins are widely used for therapeutic antibody production because they perform well, giving excellent recovery and purity. But resin-based chromatography methods are better suited to large-scale manufacture. In clinical monoclonal antibody (mAb) purification, batch sizes are small, so protein A resins are rarely used to their full lifetime potential. As a result, protein A resins may be cost-prohibitive, especially for mAb manufacturing when doses are very low or where target patient populations are small. Protein A resins…

Setting the Stage for Electronic Data Exchange

Every day, drug manufacturers must consider and address a wide range of challenges and prospects including complex regulatory requirements, intense cost pressures and the business opportunities offered by novel product classes. Transforming biopharmaceutical manufacturing with integration of intensified, continuous, predictive and autonomous operations is one solution that holds promise for streamlining operations, exploring new therapeutic modalities and meeting regulatory expectations which continue to evolve. Digitization and automation, key elements of Bioprocessing 4.0, will be essential for this transformation, in which…

Selecting the Best Transfection Method

When to Use Transfection Reagents, Viral Transduction or Electroporation No single delivery method is ideal for all situations, but researchers may routinely employ a suboptimal approach for the sake of familiarity or to avoid any start-up costs associated with new methods. In this white paper, we will describe three methods (chemical, electroporation and viral transduction) and highlight the Mirus Bio TransIT® and VirusGEN® transfection reagents and Ingenio® EZporator® Electroporation System, which are both easy to use and cost-effective. Additionally, we…