There have been tremendous efforts to make CAR T-cells more effective, safe, and persistent when treating patients. On the manufacturing side, however, errors, lot-to-lot variation, and contamination can be associated with open processes and manual handling of CAR T-cells. Cell isolation, gene editing, expansion, and cryopreservation are complex steps in a typical autologous CAR T-cell manufacturing process. Integrating this complicated multistep workflow into a closed, modular, benchtop system can facilitate transitions from laboratory scale to clinical manufacturing and improve the…

Cell Therapies

Build vs. Buy: A Critical Calculation for Cell Therapy Innovators

Cell therapy is proving to be one of the most promising advanced modalities, representing a significant step forward in the treatment of a wide range of challenging diseases and conditions. As a cell therapy candidate advances from discovery through clinical development and ultimately to commercialization, foundational decisions must be made by the product sponsor that will impact both scientific and commercial success. One of the biggest decisions is whether to build a manufacturing facility or outsource to a contract development…

Scale-Down Optimization to Scale Up Success

As immune cell therapy advances to address new indications, the need for rapid development of robust manufacturing processes becomes increasingly important. Early process optimization sets the stage for clinical and commercial manufacturing and plays a foundational role in decreasing time to market and lowering COGS. This application note describes the streamlining of T-cell expansion optimization using a DOE-based approach in a semi-automated, controlled multi-parallel setup of the Sartorius T-Cell Exploration and Characterization Solution. Download to learn about: Rapidly screening media…

Assessing Your AAV Capsid Content for Product Quality? Get the Confidence You Need with an Automated CE Platform

Looking for a hassle-free and rapid analytical method to detect full, partially filled, and empty Adeno-associated virus (AAV) capsids for your gene therapy development? Viral capsid content can impact gene therapy product efficacy and is therefore considered a Critical Quality Attribute (CQA) that must be properly evaluated during the development and manufacturing of AAVs. Traditional analytical tools such as transmission electron microscopy (TEM), analytical ultracentrifugation (AUC), and ion-exchange chromatography (IEX) can be used to characterize capsid content but are complex…

A Guide to Accelerating Cell Line Development for Commercial Production

Effective, high-quality cell line development (CLD) is essential for success in the commercialization of protein biologics, but there is no one right way to tackle it. Some companies have extensive in-house capabilities and look for reliable equipment suppliers to help streamline early-stage development and enable a smooth transition to manufacturing. On the other end of the spectrum, certain companies need a fully outsourced solution to provide cell lines, products, and experienced professionals to oversee the entire CLD project. And others…

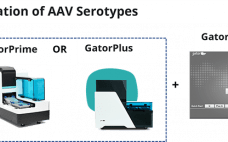

GatorTM AAVX Probes for Rapid and Label-free Quantitation of AAV Serotypes

Adeno associated virus (AAV) capsids are a leading modality for in vivo gene delivery. Complete and precise characterization of capsid particles, including capsid and vector genome concentration is necessary to safely and efficaciously dose patients. In virus development and production, it is important to determine the virus concentration at different stages of the process, optimize the clone used and obtain best production yields. Easy, rapid and cost effective quantitation methods are critical to achieve above goals. The Gator AAVX probes…

Cell Therapy Production: A Comprehensive Look at Key Elements of Success

Cell therapies offer tremendous potential to treat diseases for which there is often no treatment available. The global cell therapy market is strong and continues to expand. Market research predicts an annual growth rate of 5.4% reaching $8.83 billion by 2027. Cell and gene therapies continue to progress through the clinical pipeline with new cell therapy product approvals, expansion of approved indications for current products, as well as increasing awareness, acceptance, and use of these advanced biological products globally. This…

Evaluate Cell Therapy Product Purity with Aura CL

The CAR-T development workflow is a multi-step process that includes transfection of T cells with a viral vector to express a chimeric antigen and activation/expansion of the CAR-T using a molecule like a Dynabead conjugated to CD3/CD28. Each of these steps is a potential source of contamination that needs to be removed to ensure the purity of the final cell therapy product. Aura CL™ applies multiple detection methods to facilitate the accurate detection and identification of contaminants in a CAR-T…

Can CDMOs Provide Leadership in Cell and Gene Therapy?

Cell and gene therapies are poised to usher in a new era of healthcare. As of June 2021, 14 cell and gene therapies have been approved for clinical application in the United States, and over 400 more are in various stages of clinical trials. The hopes of many patients hinge on the success of these various programs, which are designed to deliver a significant advance on existing treatments or even a functional cure. As new cell and gene therapies get…

Autologous CAR T Cell Manufacturing Using a Semiautomatic, Closed, Modular Workflow

Cell-based chimeric antigen receptor (CAR) T cell therapies have rapidly advanced in recent years, with a variety of targets in clinical research and several FDA approved products already on the market. There has been tremendous effort to make CAR T cells more effective, safe, and persistent when treating patients. On the manufacturing side, however, errors, lot-to-lot variation, and contamination can be associated with open processes and manual handling of CAR T cells. Cell isolation, gene editing, expansion, and cryopreservation are…