As a senior leader in pharmaceutical development and manufacturing, you know that keeping up-to-date on industry trends is critical to maintaining competitive edge. But do you know how to actively drive these trends and apply them to your manufacturing processes? Are you collaborating with the right stakeholders in order to expand your capabilities and bring your innovation strategy to life? In this webinar series, three subject matter experts will share their perspective on the future of the industry and provide…

Ask the Experts

Insulin Improves Cell Growth and Influenza Yield in a HEK293 Suspension Cell Line

This webcast features: Aziza Manceur, Research Officer, National Research Council Canada To produce large quantities of vaccines in a rapid and cost-effective way is the main challenge that the vaccine industry is facing. Major changes to current bioprocesses are difficult to implement due to costs associated with the regulatory approval process. Therefore, we propose to use insulin, a protein currently used and approved in several processes and production platforms, as an additive to boost cell growth and viral production. The HEK293SF-3F6 cell…

Accelerating the Biotech Value Chain Through the Implementation of High-Throughput Technologies

This webcast features: Fredrik Nilsson, Director of Downstream Development, and Jesper Worm, PhD, Scientist, Department of Analytical Development, at CMC Biologics. In this webinar, the speakers discuss and analyze the use of high-throughput technologies to optimize timelines and deliver value within the upstream and downstream development processes, using Octet HTX platform technology. Over the past year, the experts at CMC Biologics have used this technology to deliver a significant number of titer data points, and residual protein data measurements. This…

Impact of Single-Use Tangential Flow Filtration in Downstream Bioprocessing

This webcast features: Michael LaBreck, Sales Director, Repligen TagenX Products Single-use solutions are fast becoming platform in bioprocessing as a response to pressure to optimize process economics and process efficiencies. Implementing single-use alternatives in tangential flow filtration (TFF), a critical step in downstream bioprocessing for concentration and diafiltration (buffer exchange), is a major part of this transformation. Repligen TangenX™ SIUS™ Single-use Cassettes are the first purpose-built cassettes designed for tangential flow filtration. This webinar will demonstrate how deploying these innovative…

Solving Problems in the Production of Complex Proteins and Other Biologics

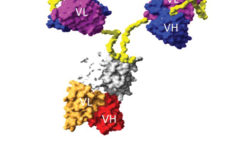

This webcast features: James Brady, PhD, VP of Technical Applications and Customer Support, MaxCyte, Inc. Moving bispecific and complex protein therapeutics from the bench to the clinic requires a scalable process that is consistent and reproducible while delivering a biologically active product. MaxCyte’s delivery platform is a high performance, electroporation-based technology that can rapidly generate milligram to gram quantities of protein in the cell line of choice. You will learn: How to express quality bi-specific antibodies, bi-specific T cell engaging…

Advanced Materials for Single-Use Biomanufacturing Systems

This webcast features: Michael W. Johnson, Business Development Engineering Manager, Life Sciences, Entegris Utilizing advanced fluoropolymer materials in single-use systems has distinct advantages in regards to extractables, chemical compatibility and cold temperature performance. This webcast examines data obtained from pilot scale testing of a new fluoropolymer single-use bag system for the freezing, storage and shipping of formulated bulk biopharmaceutical product.  You will learn: What material has the widest temperature profile from +200 to -200°C Which film material (LDPE, Polyolefin, EVAM,…

Ask the Expert Enabling Custom Solutions for Downstream Processing of Future Therapies: An Adenoassociated Virus Case Study

with Orjana Terova Orjana Terova is a purification product manager in the bioproduction division of Thermo Fisher Scientific. In a BPI webinar on 9 December 2016, she discussed the company’s custom resin program for purification of biological products. Thermo Fisher Scientific has dedicated a pilot-plant facility for this program. Terova’s Presentation Speed is the main development driver in downstream processing, but quality and efficiency are always critical. Purification processes need the highest resolution, capacity, salt tolerance, and operation speed possible.…

Improving Protein Folding Control and Scalability Using imPULSE Mixing Technology

This webcast features: Anthony Hawrylechko, Director of Microbial Bioprocess, Cytovance Protein folding by dilution is a common approach used in the manufacturing of biologics derived from microbial expression systems. This typically involves the solubilization of a washed inclusion body preparation containing the concentrated product polypeptide with a strong chaotrope or detergent solution. The denatured, inactive product solution is then diluted into a combination pH and red/ox buffer solution. Within this environment, the molecular diffusion rates of chaotrope, buffer components, and…

Effective Deployment of OPUS Pre-Packed Chromatography Columns for Bench-Scale Process Development and Process Validation

This webcast features: Tim Schroeder, Director, Product Management at Repligen GmbH Formerly Atoll pre-packed columns, OPUS® pre-packed chromatography columns for process development are used in all steps of downstream development, including screening, process validation and viral clearance, scale up and sample preparation. This webcast will demonstrate how OPUS® ValiChrom Columns, glass pre-packed columns that are exact scale-down models of corresponding full-scale chromatography columns, are ideal for process validation including viral clearance. It will also demonstrate how OPUS® RoboColumns®, miniaturized columns…

Ultimate Flexibility from Pre-Packed to Unpacked: OPUS 45R and OPUS 60R Columns

This webcast features: Fletcher Malcom, Director of Product Management, Repligen With an innovative side port that allows for easy resin unpacking, OPUS® 45R and OPUS® 60R Columns provide the ultimate flexibility in pre-packed column technology. Without compromising chromatographic performance or cleanability, the new feature helps mitigate the risk of implementing pre-packed columns in CGMP settings, and allows for re-use of the unpacked resin in other columns. This webinar covers test results on chromatographic performance, bioburden testing, shipping tests and simple…