In biopharmaceutical manufacturing, cell culture media supply critical nutrients and maintain pH and osmolality to optimize protein product yield. Because media composition and condition have a strong effect on final biologic product quality and production, biopharmaceutical companies monitor media for lot-to-lot variability. Stability testing for degradation due to light exposure, temperature changes, or shelf-life/time is possible with rapid spectroscopic methods. In an 8 October 2019 “Ask the Expert” webinar, O. Dean Stuart (product manager at Thermo Fisher Scientific) explained how…

2020

Bioengineering for “Benchtop Clinical Trials”

Animal studies can be poor predictors of human drug response. Species-specificity of organs is a concern especially for the heart. Many drugs that enter clinical trials will fail ultimately because of unexpected cardiotoxicity. Drug developers would love to mitigate such risks through in vitro human cardiac testing, but human heart biopsy materials and donor organs do not survive well in a laboratory setting. Breakthroughs with human stem cells offer an alternative. It is now possible to take a simple skin…

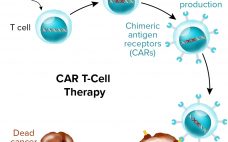

Challenges and Opportunities in CAR T-Cell Development and Manufacturing

Just about anyone in the biopharmaceutical industry will tell you that cost is now the primary concern in cell and gene therapy development. It hasn’t even been a decade since “manufacturability” was the main issue at hand — and cost has risen organically from related discussions. Regenerative medicine evolved from medical research rather than from drug-development companies, and technologies that worked in clinical settings haven’t translated directly to manufacturing facilities. Cost is often the problem. Early product successes (that ultimately…

Cell Banking for Cell and Gene Therapy: Regulatory, Ethical, and Scientific Considerations

Regenerative medicine holds great potential for human disease management, with hundreds of cell and gene therapy (CGT) products for tissue/organ reconstitution or replacement in different stages of development and clinical testing for toxicity, safety, and efficacy. For example, currently more than 60 CGTs have marketing authorization (although many with only conditional approval) from central regulatory agencies worldwide (1). Those products are treating conditions such as hematopoietic malignancies, immunological disorders, and cartilage disorders. Most of those treatments use culture-expanded autologous or…

Do We Need Separate Regulations for Advanced Therapies?

Before we had the 21 CFR 1271 regulation for tissue therapies, the US Food and Drug Administration (FDA) had determined that regenerative medicine was exceptional enough to warrant its own regulations for good manufacturing practice (GMP). Since 2001, the tissue industry has adapted to those new rules while the FDA stepped up enforcement over time. When a cell or tissue product is regulated under 21 CFR 1271, its specific regulations apply before the general regulations for biologics and drugs. But…

CAR-T at the Crossroads: Is Allogeneic the Way to Go?

As cell therapies move through the clinic toward commercialization, respondents to an Informa Connect industry survey are beginning to look to allogeneic — or off-the-shelf — products as “the next big thing.” Almost 200 people contributed to the Cell Therapy Analytics Report, revealing their current positions within the burgeoning cell and gene therapy space and offering their thoughts and predictions for the future. Most survey respondents work within companies developing oncology products. Of those, the largest group (41%) said that…

eBook: Joining Forces — Industry Collaborations Toward BioProcess Success

Companies in the biopharmaceutical industry increasingly are working together to solve the many challenges of product/process development and biomanufacturing. Suppliers seek end-user help in refining technologies; academics and small innovators attract the financing and business acumen of large companies; equal partners share in technological problem-solving; and sponsors engage the development expertise of contract research and manufacturing organizations. Other examples of biopharma industry collaborations abound, too. Citing critical examples from the September 2019 BioProcess International East Conference in Boston, MA, this…

Upstream: Make the Right Decisions for Your mAb

Bioprocess decisions made during upstream operations can be difficult to reverse at later, more costly stages of biologic manufacture. They even can require significant backtracking, wasting precious time, labor, and material. Read this Special Report to learn ways to optimize monoclonal antibody bioprocessing upstream. Specifically, you will learn about different tools that small and emerging biotechnology groups can use to ensure robust cell-line selection novel media formulations designed for intensified upstream processing in perfusion modes mixing and delivery solutions that…

The Proof Is in the Data: Extractables and Leachables

Extractables and leachables (E&Ls) must be addressed in material and process validation programs. Extractables are compounds that can be extracted from a material in the presence of solvents with varying polarity under extreme conditions. Materials manufacturers should make extractables guides available to end users. Leachables are compounds that migrate from a material in the presence of an actual formulation under normal process operating conditions. Extractables information can be helpful as a basis for evaluation of potential process-equipment–related leachables (PERLs)testing. However,…