Welcome New Editorial Advisor Kavita Ramalingam Iyer is associate director and product lead of GRACS-CMC for vaccines at Merck Sharp & Dohme Corp. She received her PhD in biotechnology from Anna University (India) and completed a postdoctoral fellowship at the University of Minnesota (focusing on antibody engineering and synthetic biology) before joining Merck in 2008. Kavita has over 10 years of pharmaceutical industry experience leading chemistry, manufacturing, and controls (CMC) development; manufacturing; establishment of good manufacturing practice (GMP) facilities; technology…

2018

Back to Basics for Biotech: Driving a Culture of Quality and Compliance with Practical Communication Techniques

The robust regulatory environment surrounding biotechnology and bioprocessing demands a comprehensive current good manufacturing practice (CGMP) culture of quality, compliance, and absolute adherence to policy. Employees need to be engaged in their work, with a laser focus on meeting stringent specifications and operating under tight controls. A misstep in quality or compliance can lead to hefty fines, legal concerns, regulatory retaliation, and reputational damage. Communication and stakeholder engagement are critical to aligning organizations and driving the right culture in highly…

A Two-Step Purification Process: Application of HIC Membrane Chromatography in a Disposable 2,000-L Clinical Facility

Given paradigm shifts in the biopharmaceutical industry over the past decade, product development timelines are squeezed as the number of molecules entering clinical development continues to increase. Manufacturing facilities, especially those supplying clinical trial materials, have had to adapt to this trend. One popular approach is to have fully disposable equipment that allows for quick product changeover and flexible manufacturing capacity to respond to variable clinical demand. Although many facilities-related technologies exist to support that concept (e.g., disposable probes and…

IgG Purification By Ultrafiltration: Time for Another Look

One of the early disappointments in development of immunoglobulin G (IgG) purification technology was ultrafiltration on membranes with 50–100 kDa cutoffs. Sodium dodecyl sulfate polyacrylamide gel electrophoresis (SDS-PAGE) showed that most host cell proteins were smaller than that. IgG was retained. Parallel concentration and buffer exchange could be performed going into a follow-on polishing step. These features made it an obvious candidate for initial capture, but it did not perform as hoped. Membrane fouling sabotaged its concentration–diafiltration potential, and prohibitive…

Enhanced Galactosylation of Monoclonal Antibodies: Using Medium Supplements and Precursors of UDP-Galactose, Part 2

In Part 1 of this report, we described our development of a high-throughput assay for analyzing monoclonal antibody (MAb) glycans and how we used it to evaluate the effects of medium supplements on galactosylation of MAbs produced by two different cell lines (1). This month, we examine galactosylation of a MAb produced by a third cell line. A discussion follows on the benefits of this high-throughput assay before we highlight the similarities and differences in galactosylation among the three MAbs…

Large-Scale Purification of Factor-IX: Comparing Two Affinity Chromatography Resins

Human clotting factor-IX (F-IX) is a glycoprotein that is essential for normal hemostasis (1). A deficiency of F-IX in human plasma is caused by an absence or functional mutation of the F-IX gene that expresses inactive F-IX in plasma. That leads to hemophilia B (“Christmas disease,” named after its first identified patient), a genetic disorder in which the blood-clotting cascade is disturbed (2, 3). The structure and amino-acid sequence of F-IX are similar to those found in other vitamin-K–dependent glycoproteins.…

Advanced Viral Clearance Study Design: A Total Viral Challenge Approach to Virus Filtration

Biologics derived from mammalian organisms have been accepted for therapeutic use for almost a century (1). However, these pharmaceuticals have the potential for contamination with pathogenic adventitious agents such as viruses. With cell-line–derived recombinant proteins, the viral risks commonly include viruses in the Retroviridae and Parvoviridae families (2). As patient safety and manufacturing facility suitability became significant concerns in the 1980s and 1990s, several industry and regulatory bodies reached consensus on how to approach the unique challenges of viral safety…

Evaluating Adsorptive Filtration As a Unit Operation for Virus Removal

Most recombinant monoclonal antibodies (MAbs) are produced by mammalian cells. Because biopharmaceuticals derived from mammalian tissue culture carry the risk of adventitious virus contamination, regulatory agencies expect risk-mitigation strategies to include validation of purification unit operations for their ability to clear viruses (1). Guidelines from the International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH) describe how to prove viral clearance in downstream purification processes using an orthogonal approach (2). Viral log10 reduction values (LRVs) are…

Reverse Translational Medicine: The Promising Future of Failure

The drug development landscape is awash with candidates that have shown enormous promise and efficacy in preclinical models but failed when administered to clinical trial subjects. Although such failures occur for different reasons, one of the most pervasive causes is the inability of preclinical models to recapitulate human physiology accurately. Despite advances with both in vitro and in vivo models, improving those toward a more accurate avatar of the human physiological process remains a challenge. Central to that effort will…

eBook: Viral Vaccine Production — Cultivation of Vero Cells in Packed-Bed Bioreactors

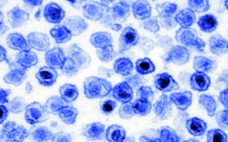

Vero cells are anchorage-dependent cells that are used widely as a platform for viral vaccine production (1). In stirred-tank bioreactors, they are grown ordinarily on microcarriers. Fibra-Cel disks are an alternative attachment matrix because they provide a three-dimensional environment that protects cells from damaging shear forces. However, such disks have not been tested for the cultivation of Vero cells. We tested whether benchtop single-use and glass bioreactors with a packed bed made of Fibra-Cel disks would be suitable for cultivation…