The increasing role and importance of cell culture in biophamaceutical manufacturing has led to considerable research and development (R&D) into bioreactor design and performance in recent years. As a result, a greater understanding of bioreactor fluid dynamics and critical physical parameters is now essential to maximize cell growth and productivity. Stirred-tank bioreactors are especially important in this development process because of their favorable properties in areas such as mixing efficiency and homogeneity, energy transfer, and scalability. The design and manufacture…

2016

Harnessing the Power of Big Data to Improve Drug R&D

Like many other industries, biotechnology is being transformed by the emergence of big data — extremely large data sets that can be analyzed to reveal patterns, trends, and associations — and advanced analytics. Information from multiple sources such as electronic health records, payer claims, and mobile health platforms is growing exponentially. When used and harnessed properly, these data can boost the efficiency of drug research and development (R&D) in three critical areas: early R&D investment, drug development, and personalized medicine.…

From the Editor

Our second annual BPI Theaters supplement once again brings you summaries from presentations at our BioProcess Theaters during Interphex and the BIO Convention.As a summer companion piece to our annual Yearbook’s company profiles and application notes, this serves as a midyear overview of the biopharmaceutical landscape. These summaries are the highlights.To hear the full presentations (and see their PowerPoint slides) please go to www.bioprocessintl.com/Interphex2016 www.bioprocessintl.com/BIO2016 This special summer issue comes to you through the efforts of many people.Our publisher, Brian…

Deciding Between Single-Use and Stainless Steel Strategies

A BPI Theater Roundtable at Interphex 2016 On Tuesday, 26 April 2016, Eric S. Langer (managing partner of BioPlan Associates) chaired a morning roundtable titled “Deciding on Single-Use vs. Stainless Steel Strategy: What the CMOs Know That Biopharma Needs” as a follow-up to a similar discussion held last year. Langer brought together a panel of four contract manufacturing organization (CMO) industry experts: Daniel Vellom (senior director of global technology innovation at Sanofi Pasteur) Sue Behrens (senior director of process technology…

Coordination of Single-Use System Standards and Best-Practice Efforts

A BPI Theater Roundtable at Interphex 2016 On Tuesday, 26 April 2016, James D. Vogel (founder and director of The BioProcess Institute at the University of Rhode Island) chaired a midday roundtable titled, “Single-Use Harmonization Town Hall: Coordination of SUS Standards and Best Practice Efforts.” Two industry experts joined him in a panel discussion: Mike Johnson (business development engineering manager for Entegris) Jeff Carter (strategic projects leader at GE Healthcare). All three are members of different groups interested in developing…

Single-Use Benchtop Bioreactor System for Mammalian Cell Culture and Recombinant Protein Production

Mark Arjona (product line manager, Distek) 1:00–1:20 pm The bioprocessing industry has embraced single-use technologies recognizing their benefits of safety, cost, and throughput. Based in New Jersey, Distek is a leading manufacturer of single-use equipment. The BIOne is a single-use bioreactor system consisting of a patent-pending, disposable headplate and liner that fit together into a bench-scale glass vessel. The liner molds to the contours of culture vessels (3 L or 7 L), keeping their geometry, aspect ratio, and volume all…

Qualification and Application for Single-Use In-Line Sensors in Bioprocessing

Jim Furey (general manager, PendoTECH) BPI Theater @ INTERPHEX, April 26, 2016 11:30 am–12:00 pm Located in Princeton, NJ, PendoTECH was founded in 2005. The company develops equipment for single-use systems and promotes the concept of automation. It produces sensors, monitors, transmitters, and standard process control systems with the ability to collect and store data, as well as customized solutions. PendoTECH staff have many decades of experience in product development, project management, embedded software development, graphical-interface programs, and mechanical engineering.…

The Evolution of Upstream Bioprocessing: Mitigating Risk Through Single-Use and Cell Culture Technologies

Josh Hays (upstream technology director, MilliporeSigma), BPI Theater @ INTERPHEX, April 26, 2016, 1:20–1:40 pm Over the past 10 years, upstream processing has undergone a considerable evolution. Single-use technologies up to the 2,000-L scale have become the “gold standard” to deliver a fast, flexible, and cost-effective solution for production of recombinant proteins in a current good manufacturing practice (CGMP) environment. Cell culture media advances through speed and flexibility enhancements as raw-material modifications (along with supply continuity and reduced overall cost…

Significant Technology Advances Enabling Integrated Continuous Bioprocessing

Peter Levison (senior director, Pall Life Sciences ) BPI Theater @ INTERPHEX April 26, 2016, 1:40–2:00 pm Pall’s advancements in integrated continuous bioprocessing include new product launches. The company has built a continuous laboratory at its facility in Westborough, MA. It is 6 m Ă— 6 m and can produce >2 g of pure monoclonal antibody (MAb) per hour. One continuous process flows through one step to the next, from cell culture to formulation. Continuous manufacturing is being used successfully…

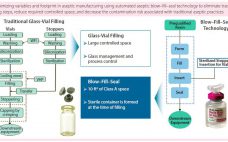

Delivering Unique Sterile Primary Container Closures with Advanced Aseptic Manufacturing

Bill Hartzel (director of strategic execution, Catalent Pharma Solutions) BPI Theater at INTERPHEX, April 27, 2016 11:00–11:20 am How do biopharmaceutical companies leverage technology to provide unique primary container– closures to the market space? Catalent uses an advanced aseptic process of blow–fill–seal (BFS) technology. Adding automation makes for an efficient process that can reduce or eliminate human intervention needed in critical drug-product filling applications. Catalent’s system uses one automated machine in which a container is quickly formed, filled, and sealed…