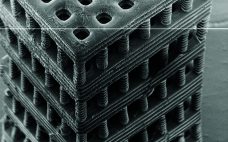

Commonly referred to as three-dimensional (3D) printing, additive manufacturing encompasses a set of technologies that fabricate objects in an additive way, layer by layer, rather than conventional means of fabrications that generally subtract unwanted material from a larger block. Precise control over material placement allows 3D printing to fabricate objects that otherwise would not be manufacturable. Although many of these technologies have been around for two or three decades, recently they have received a significant amount of attention from industry,…

2016

Mass Spectrometric Conjugate Characterization: Process Qualification of Recombinant Protein–Hapten Conjugation

Conjugated protein biotherapeutics such as PEGylated proteins (with polyethylene glycol), antibody–drug conjugates (ADCs), and protein–haptens often present unique analytical challenges related to characterizing the conjugation aspect of their manufacturing processes. Analytical characterization of this class of proteins requires knowledge of the sites of conjugation, the degree of conjugation, and the drug-to-protein ratio. Here we present case studies in development of reliable methods based on mass spectrometry (MS) to characterize a protein–hapten drug substance during late-phase process validation. This protein is…

Providing Lipids Boosts Protein Productivity: Testing a Feed Supplement with Multiple Cell Clones and Media Formulations

As the biologics (and now biosimilar) markets continue to grow, pressure increases on biomanufacturers to reduce cost of goods sold (CoGS). One way they can reduce cost is by increasing protein productivity in terms of protein titer per volume of culture. Media optimization is a key strategy for increasing protein productivity. In the past few decades, average titers across the industry have increased greatly — from <0.5 g/L in the 1980s to >3 g/L today, and it is not uncommon…

Advanced Protein Engineering Enhances Biopharmaceutical Manufacturing and Analytics

Production of proteins for pharmaceutical use is a complex, multistep process that requires technologies for purifying such molecules from highly complex biological mixtures. It also calls for reliable, cost-effective, high-throughput analytical techniques to determine protein quality and functionality to ensure the safety and efficacy of end-products. Mistakes in product development and manufacturing not only are immensely costly, but they can also put patients at risk. Many well-established processes and analytical tools are available for use in manufacturing antibody drugs (e.g.,…

Ask the Expert: Top Five Considerations in Outsourcing to a Biomanufacturing Partner

with Paul Jorjorian In BPI’s 5 October 2016 webcast, Paul Jorjorian (director of global technology transfer at Patheon) discussed his top five considerations for companies outsourcing to a biomanufacturing partner. Jorjorian’s Presentation Selecting a contract and development manufacturing organization (CDMO) is an important decision for many biopharmaceutical companies. Beyond time and cost, here are some other criteria to consider. The number-one issue is quality. Is your company’s definition of quality the same as a CDMOs — and if…

Ask the Expert: Boosting Profits with Single-Use Powder Transfer

with Chris Rombach Open-suite biomanufacturing is gaining popularity. But it leaves surfaces open to contamination, workers at risk for exposure to airborne particulates, and processes more exposed to product loss due to waste or spillage. Liquid-handling systems are often adapted for dry-powder applications, but flow rates, handling characteristics, and dispensing volumes differ dramatically. ILC Dover’s purpose-built, single-use EZ BioPac system is designed specifically to contain and release dry powders. With single-use bags engineered for the task, it can…

Ask the Expert: BioSC Continuous Chromatography of MAbs, Process Design and Regulatory Considerations

with Vincent Monchois In our September webcast, Vincent Monchois (biopharma strategic project director at Novasep) discussed continuous chromatography using BioSC technology. He included regulatory considerations and the challenges of viral clearance that arise when companies switch from batch to continuous processes. Monchois’s Presentation Users can apply BioSC multicolumn, continuous chromatography to standard capture steps such as ion-exchange or protein A chromatography. The main advantages are continuous operation and full access to the total static capacity of a resin.…

Special Report: A Strategy for Cost-Effective Capture Using Agarose-Based Protein A Resins

It is well recognized that the cost of Protein A resins is substantial. If a developmental monoclonal antibody (MAb) makes it to marketing approval and manufacturing, the high cost of purification using a Protein A resin is amortized over a large number of purification cycles, and the contribution to cost of goods is reduced to acceptable levels. However, a high percentage of clinical projects will fail, and the Protein A resin will be used only for a small number of…

October Supplement From the Editor

Good things come in small packages — like this issue, for example. Each author brings a critical aspect of regenerative medicine development into perspective, highlighting progress and remaining challenges. I am especially pleased to highlight the current stage of gene therapies. At cell therapy conferences a few years ago, some people insisted to me that quality by design (QbD) would have little to no relevance for these advanced therapies. Speakers were academic and medical researchers or commercial manufacturers of traditional…

Progress Toward Commercial Scale and Efficiency in Cell Therapy Bioprocessing

Regenerative medicine includes both cell and gene therapies. Currently 672 regenerative medicine companies operate around the world, and 20 products have been approved by the US Food and Drug Administration (FDA). Of 631 ongoing clinical trials by the end of 2015 (1), over 40% are in oncology, followed in prominence by cardiovascular and infectious diseases. Here I focus on gene and cell therapy bioprocessing in which the final products delivered to patients are cells. Cell therapies are either autologous (derived…