Over recent decades, protein-based therapeutics have emerged as key drivers of growth in the pharmaceutical industry. Drug development pipelines have filled with biologics, and a handful of monoclonal antibody (MAb) products have become some of the best-selling drugs around the world. Production of biotherapeutics is often challenging because of the inherent instability of these large, complex molecules. Their fragile nature has forced manufacturers to change how bulk drug substances (BDSs) are handled and final drug product is formulated, sterile filtered,…

2016

Contract Manufacturing of Cell Therapies: A Conversation with MaSTherCell’s Eric Mathieu and Thibault Jonckheere

The work of developing advanced medical products is spreading around the globe, and with it comes specialized contract services. Far from a “one size fits all” approach to development, and with few platform technologies yet available, contract service providers in the advanced therapeutics space must focus on helping to move promising science into good manufacturing practice (GMP) environments, but with regulatory pathways and eventual harmonization still under development. One company that formed to address the specific needs of cell therapy…

From the Editor

Every now and then in the biopharmaceutical industry, a technology or concept seems to take hold and suddenly appears everywhere — in print, at conferences, in workshops and online media offerings, and as part of new product launches. This happened in the 1990s when process validation was (seemingly suddenly) the theme of the day, and it happened briefly later that decade when transgenics appeared to be a potential game changer. Single-use technologies of course precipitated arguably the most widespread set…

Spotlight

Niche Disease: Autoimmune/Noninfectious Uveitis Uveitis is the inflammation of the uvea, the pigmented layer that lies between the eye’s inner retina and its outer fibrous layer composed of the sclera and cornea. The most frequent etiologies are autoimmune diseases such as Behçet disease. Noninfectious intermediate and posterior uveitis (NIU) represents 10–15% of uveitis cases, making it the fourth leading cause of blindness in the developed world. About one in 4,500 patients suffer with this condition. Uveitis typically has been treated…

Bioreactor Manufacturing Platforms for Cell Therapies

As an increasing number of cell therapies move into late-phase trials, developers are considering innovative solutions to address scale-up and commercialization challenges. Many of their questions focus on the technologies and engineering strategies that will be needed to optimize their processes, especially bioreactors. At the January 2016 Phacilitate Cell and Gene Therapy World conference, Siddharth Gupta, a scientist at Lonza (Walkersville, MD), talked about the effects of upstream process decisions on product quality in his presentation “Bioreactor Manufacturing Platforms: So…

Special Report on Continuous Bioprocessing: Upstream, Downstream, Ready for Prime Time?

Once an engineering curiosity and smallscale laboratory technique, continuous bioprocessing has evolved in just a few short years to a topic of intense and increasing interest to most bioprocessors. Critics point to a steep learning/adoption curve, but that is nothing new in biomanufacturing.Andrew Zydney is a distinguished professor of chemical engineering at Pennsylvania State University. He has noted these challenges facing continuous processing: commercially unproven unit operations (especially downstream), a lack of equipment robustness, sterility concerns, and uncertain development timelines…

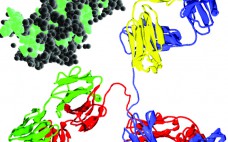

Clearance of Persistent Small-Molecule Impurities: Alternative Strategies

Small-molecule impurities that bind to and copurify with protein biopharmaceuticals traditionally have been removed using bind-and-elute (BE) chromatography. However, that approach may be undesirable for a number of reasons. For instance, it may present a facility-fit challenge or provide a lower process yield than what is acceptable. A common scenario in which BE chromatography may be undesirable is in removal of unreacted conjugation reagents. Bioconjugates represent an important and growing class of pharmaceuticals that include PEGylated proteins, vaccines, and antibody–drug…

Best Practices for Critical Sterile Filter Operation: A Case Study

A number of regulatory guidelines recommend preuse integrity testing of critical sterilizing liquid filters for aseptic processing (1–3). Before sterilization, a preuse test will confirm that a filter is installed properly and was not damaged during shipment or handling. Performing a preuse test after sterilization detects damage that may have occurred during the sterilization cycle. Testing after sterilization limits risk, so it is a practice applied based on risk assessment. Because it is perceived to reduce business loss risk, preuse…

Accelerated, Seamless Antibody Purification: Process Intensification with Continuous Disposable Technology

Process intensification through continuous manufacturing has been practiced in the chemical, petrochemical, and food industries for years and has gained much interest among biopharmaceutical manufacturers (1). Key drivers encouraging biomanufacturers of therapeutic molecules to convert batch processes into continuous operation include flexibility, productivity, cost effectiveness, and product consistency. Continuous upstream processing has been demonstrated for the manufacture of a broad range of molecules, including complex/labile proteins such as enzymes (2) and monoclonal antibodies (3). Recent publications have reported successful application…

Validation of Controlled Freezing and Thawing Rates: A 16-L–Bag Study

It is well understood that freeze– thaw processes affect the product quality of biopharmaceuticals (1–3). It has been reported that there is no consistent method of controlled freezing and thawing rates for biological formulations (4). Traditionally, ultralow temperature storage chambers that were not designed for freezing have been used to provide an energy state for the environment surrounding the product with very little excess capacity to change the state of the product. This study details a consistent method for controlled-rate…