Richter-Helm has more than 25 years of experience in the development and good manufacturing practice (GMP)–compliant production of a wide range of biopharmaceuticals, including recombinant proteins (e.g. cytokines, growth factors, antibody fragments, surface antigens) plasmid DNA microbial vaccines (e.g., live and attenuated whole cell vaccines), according to the EU and US GMP guidelines (FDA approval 2013). Customized Solutions Richter-Helm offers customized solutions for all steps in biopharmaceutical projects through contract development and manufacturing services, including Development of production strains (Escherichia…

Industry Yearbook 2014-2015

Sandoz: Provider of Customized Solutions in Biotech Manufacturing

Sandoz is one of the leading specialists in biotech development and manufacturing. Comprehensive know-how is based on more than two decades in microbial and mammalian cell culture production at commercial scale. Today Sandoz offers a broad variety of integrated services, including innovative expression systems, process development, scale-up, and production of recombinant products derived from microbial systems and mammalian cell culture in state-of-the-art facilities. Our expertise is based on numerous projects successfully performed in collaboration with our customers. Currently, Sandoz is…

Client Experience Matters!

Contract manufacturing of biologics is more than having superior technology — it’s having experienced people who are passionate, responsive, and committed to developing and manufacturing your biotherapeutics to improve patient care. As a fully integrated contract development and manufacturing organization (CDMO), Therapure Biomanufacturing has the scientific and technical expertise to successfully deliver at every stage of product development (preclinical, clinical, and commercial). Our 130,000-ft2 (12,000-m2) current good manufacturing practice (cGMP) manufacturing facility meets FDA, EMA, and HPFB regulatory standards and…

Vetter Development Services: Filling Your Clinical Development Needs in Chicago

Vetter, a leading provider of aseptically prefilled drug-delivery systems, operates a state-of-the-art facility at the Illinois Science and Technology Park in suburban Chicago. The site offers a central US location with a domestic and international airline hub. It is uniquely situated in a thriving biopharmaceutical region that offers an established infrastructure and prominent research institutions. The company’s Chicago site supports preclinical through phase 2 development projects. The 27,000-ft2 facility’s functional areas include microbiology and chemical analysis laboratories; materials preparation; compounding;…

The Microbial CMO: Discovering Expertise in a New Scale

Wacker Biotech GmbH is “The Microbial CMO” — the partner of choice for the contract manufacturing of therapeutic proteins in microbial systems. The company is built on more than 20 years of experience in biopharmaceutical manufacturing. Founded in 1999 as a spin-off from the Hans- Knöll Institute in Jena, Wacker Biotech is a 100% subsidiary of Wacker Chemie AG since 2005. Wacker’s integrated service portfolio covers molecular biology, process and analytical development, and the GMP manufacturing of biologics for clinical…

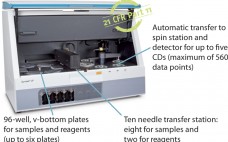

Improving Efficiency and Throughput for Titer and Impurity Bioanalytics: Using an Automated, Nanoliter-Scale Immunoassay Platform

Increasing efficiency and productivity for titer and impurity bioanalytics is even more critical as a result of increasing workloads in supporting multiple programs with limited resources. Current methods such as enzyme-linked immunosorbent assay (ELISA) or high-performance liquid chromatography (HPLC) create bottlenecks in critical workflows because of throughput constraints, repeat testing, or longer assay times. The Gyrolabâ„¢ workstation is an automated immunoassay platform that can generate high-quality analytical data at high throughput using nanoliter volumes for more rapid and efficient titer…

Biopharmaceutical Product Development: Helping to Develop Better Biologic Products, Faster

From drug and biologic development services to delivery technologies to supply solutions, we are the catalyst for your success. With over 80 years of experience, we have the deepest expertise, broadest offerings, and the most innovative technologies to help you get more molecules to market faster, enhance product performance, and provide superior, reliable manufacturing and improved results. Catalent is your strategic partner for biologic drug development success. SMARTagâ„¢ ADC Technology for the Development of Optimized Antibody–Drug Conjugates: Catalent has an…

Automated Rapid Microbial Methods: Taking Environmental Monitoring Testing Out of the QC Labs

Environmental monitoring of clean rooms is an integral part of a pharmaceutical company’s quality control testing program. Analyzing the air, surface, and personnel within cleanrooms helps ensure the manufacturing environment meets mandated standards and that any variations can be addressed. Unfortunately, the traditional method for environmental monitoring is manual, inefficient, and time consuming. Laboratory technicians must travel, sometimes across large campuses, to collect samples in manufacturing suites. Technicians have to gown, take the samples, and travel back across the campus…

Bacterial Endotoxin Testing: New Method for Unmasking Endotoxin in Biopharmaceuticals

Following the initial observations by Chen et al., leading manufacturers of biopharmaceuticals have determined that endotoxin (LPS) can be “masked” in biopharmaceutical formulations typically containing phosphate, polysorbate, and sugars (1). Being in a masked state, endotoxin is undetectable by the commonly used factor C detection methods such as the Limulus amebocyte lysate test (LAL). This phenomenon has also been denominated low endotoxin recovery (LER). As previously shown by Reich et al. (2), endotoxin masking is time dependent, meaning that…