Before a medicinal product can be considered suitable for patients, it must go through laborious testing and cost-effectiveness analysis. In addition, all medicinal products must be authorized before they can be sold on the market and thus made available to patients (1). This is the case in the European Union (EU) and European Economic Area (EEA) countries as well as in the United States (US). Every year, a number of medicines receive marketing authorization. In their wake, however, several thousand…

Author Archives: Shada Warreth

eBook: Downstream Processing — An Overview of MAb Purification Methods

The downstream harvest, clarification, and purification operations of biologics are essential steps to ensure drug product safety. However, these process steps can be problematic for complex biologics. Compared with processes for traditional small-molecule pharmaceuticals, downstream methods for monoclonal antibodies (MAbs) have higher risks of contamination. Thus, different centrifugation, filtration, chromatography technology and viral clearance/inactivation strategies must be applied to remove dead cells, host-cell proteins, viruses, and other contaminants. Several factors must be considered to determine which methods and technologies are…

Applications of Disposable Technologies for Upstream Bioprocessing

Over the past 10 years, a number of developments in disposable (limited use) and single-use technologies (SUTs) have been made for different bioprocess operations. Until recent years, much of the industry’s process equipment was sterilized using thermal methods such as autoclaving. Most equipment was reusable and required cleaning and sterilization before use. Such processes required validation and expensive and time-consuming resources. Production facilities relied on hard-piped, inflexible equipment such as large stainless-steel bioreactors and holding tanks. However, advanced SUTs now…

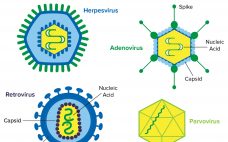

Detection and Clearance of Viruses in the Biopharmaceutical Industry

Viral contamination is a common threat to all animal- and human-derived biopharmaceuticals. This type of contamination can affect any part of a bioproduction process, so biomanufacturers need to perform viral testing studies and incorporate viral clearance methods into their processes. Viral contaminants can come from cell lines (e.g., endogenous retroviruses) or from adventitious (e.g., mycoplasma) introduction during drug manufacturing. Virus testing of master cell banks (MCBs), working cell banks (WCBs), end-of-production cell banks, and bulk unprocessed harvest material is called…