Cells and cell debris are removed between fermentation (upstream) and product cleaning (downstream) during a process called midstream. Midstream processes often are performed by combining several unit operations (1). A highly efficient method is cake filtration, which can be conducted using a FILTRODISC™ BIO SD depth filter. Here, I describe the cleaning of fermentation broths using cake filtration. This technology can maximize product yield and economic efficiency. With increasing particle loads (>108 cells/mL), standard technologies (e.g., centrifugation, separation, and membrane-…

Author Archives: Ralph Daumke

Making Downstream Processing Continuous and Robust: A Virtual Roundtable

Current biomanufacturing is driven to pursue continuous processing for cost reduction and increased productivity, especially for monoclonal antibody (MAb) production and manufacturing. Although many technologies are now available and have been implemented in biodevelopment, implementation for large-scale production is still in its infancy. In a lively roundtable discussion at the BPI West conference in Santa Clara, CA (11 March 2019), participants touched on a number of important issues still to be resolved and technologies that are still in need of…

Endotoxin Removal in a New Scalable Dimension

Endotoxins are degradation products from dying gram-negative bacteria and complex aggregates of acidic lipopolysaccharides (LPS). Each is composed of lipophilic lipids and hydrophilic polysaccharides. In humans, endotoxins can cause immune responses such as fever (pyrogenic threshold is approximately 0.1 ng/kg body weight). Unlike bacteria themselves, endotoxins are extremely heat and pH stable and therefore withstand sterilization methods. During protein purification, the reduction of endotoxins is one of the most important and difficult steps. It often includes complex purification strategies (e.g.,…

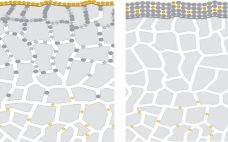

Increased Clarification Capacity: Using Filter Aid and FILTRODISCâ„¢ BIO SD for an Economical Filtration

Clarification of fermentation broths is one of the most important steps in bioprocessing. The first purification step after fermentation is the cell harvest, which is designed to remove cells and cell debris as well as to reach maximum product yield in compliance with existing regulatory environments. Standard technologies (centrifugation, separators, membrane, and depth filtration) can no longer handle the high particle loads (>108 cells/mL) in an economical way. Deciding on the right purification system involves addressing questions about process performance,…