Molly McGlaughlin, director of strategy and business development, BioVectra Jim Stout, director of process science, BioVectra  McGlaughlin introduced BioVectra. The company has been in business for 45 years and is based in Canada. Its a well-established contract development and manufacturing organization (CDMO) and fine-chemical manufacturer, and is a subsidiary of Mallinckrodt Pharmaceuticals. BioVectra started out as diagnostic reagent company and now has a complementary set of niche capabilities. From 10 years of fermentation experience, it was a logical progression to…

Author Archives: James Stout

Membrane Adsorbers, Columns: Single-Use Alternatives to Resin Chromatography

Filtration membranes are used extensively throughout the biopharmaceutical industry for a range of applications, from coarse filtration to nanofiltration. Advantages of filter technologies include easy scaling, disposability, and (for many membrane filters) rapid and robust performance in a single-pass. The same advantages have been realized with membrane adsorbers. Chromatography resins are inherently disadvantaged by diffusion limits of the pores in chromatography media. Therefore, resin columns must be significantly oversized to match the performance of high productivity bioreactors. By comparison, membrane…

NatriFlo® HD-Q Membrane Adsorber: A New Single-Use High-Capacity Polishing Tool with Excellent Salt Tolerance and Process Robustness for MAb Purification

Strong anion exchange (Q) chromatography has become an industry standard in MAb production. It is a proven technology to remove DNA, viruses, endotoxins and acidic host cell proteins from process feed streams in flowthrough mode. Recent trends show an increasing interest in downstream single-use technologies and flexible biomanufacturing due to advancement in cell culture technology and emergence of biosimilars. Traditional chromatography columns are slow, often oversized and not suitable for flexible biomanufacturing. Conventional membrane adsorbers cannot provide sufficient process robustness…

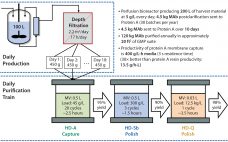

Monoclonal Antibody Production – Viral Clearance and Host-Cell Protein Reduction Using a High-Capacity, Single-Use, Strong Anion-Exchange Device

Strong anion-exchange (Q) chromatography is an industry standard for polishing purification steps of monoclonal antibody (MAb) production. It is a proven technology that removes viruses and host-cell proteins (HCP) from process feed streams in flow-through mode. NatriFlo HD-Q device adsorbers feature a hydrogel membrane, which combines high dynamic binding capacity and salt tolerance to deliver best-in-class performance. This makes it possible to rapidly process-large sample volumes using a small disposable device. This article examines the ability of NatriFlo HD-Q adsorbers…

High-Capacity, Single-Use, Strong Anion-Exchange (Q) Chromatography Tools: Speed and Process Flexibility for MAb Purification

Strong anion-exchange (Q) chromatography is an industry standard for polishing purification steps of monoclonal antibody (MAb) production. It is a proven technology that removes DNA, viruses, endotoxins, and acidic host-cell proteins (HCPs) from process feed streams in flow-through mode. Advancements in cell culture technology, the emergence of cost-sensitive biosimilars, and the limitations of conventional purification technologies have led to an industry-wide interest in downstream single-use technologies and more flexible biomanufacturing options. Despite their high binding capacity, traditional resin-based chromatography columns…