We editors think of the “manufacturing” theme as a sort of catch-all category for technical issues that aren’t specifically protein-production or separation/purification related. For us, that has always included assay development and other analytical topics that are more product- than process-focused. For the purposes of this conference-guide supplement, however, we have developed a separate article for analytical matters. So what falls under manufacturing? In past BPI Conferences, tracks such as “Production and Economics” and “Scaling Up from Bench to Clinic”…

Author Archives: BPI Contributor

Analytics and Quality

Since the concept of “well-characterized biologics” entered the biopharmaceutical industry’s vernacular late in the 20th century, increasing emphasis has been placed upon product and process characterization. Analytical laboratories have always been vital to bioprocessing, whether they were performing in-house quality assessments, preformulation and other types of product characterization, and process scale-up and optimization support, or outsourced viral safety and product testing. Recent advances in analytical technologies such as high-performance liquid chromatography (HPLC) and mass spectrometry (MS), as well as other…

Poster Presentations

Cell Culture and Upstream Processing Gary Boch (Cevec Pharmaceuticals) Custom Chemically Defined Media for CAP-T Cells Maurizio Cattaneo (BioVolutions) DoE for Continuous BioProcessing of Therapeutic Monoclonal Antibodies Stephanie Dubois (ATMI LifeSciences) Linear Scalability of Virus Production in Integrity®iCELLis®Single-Use, Fixed-Bed Bioreactors from Bench Scale to Industrial Scale Thomas Falkman (GE Healthcare) Assessment of Process Performance and Product Quality in High-Performing Fed-Batch Cultures Kathleen Harrison (Frieslandcampina Domo) Influence of Soy Protein Hydrolysates on Robustness of Cell Culture Experiments Clint Pepper (Bend Research)…

Mirus TransIT-PRO® Transfection Kit for Biotherapeutic Protein Production

Decrease time to produce usable protein by maximizing target protein yields through transient transfection. The TransIT-PRO® Transfection Kit uses animal origin free components designed for high and reproducible nucleic acid delivery into suspension CHO and 293 derived cells. Since it is compatible with varied media formulations, the same media can be used for both transient and stable expression. The TransIT-PRO outperforms linear PEI in protein yield, while providing a cost-effective alternative to FreeStyle™ MAX and 293Fectin™ Transfection Reagents.

September 2013 Issue Author Insights

Control Over Your Microbial Identification Using the Gold-Standard Genotypic Method

Eliminate your outsourcing needs! Gain visibility and control. Learn how the next-generation, high-throughput MicroSEQ® system delivers right-first-time accuracy and give you complete control over microbial identification, by owning the system, the process and data analysis.

Charge Heterogeneity Analysis in 10 Minutes

Platform methods, high resolution and ease of use have made the iCE system the gold standard for protein charge heterogeneity characterization for biopharmaceuticals. At 15-18 minutes per sample, iCE methods are already fast and simple but now they are even better. In this white paper we describe a high throughput 10 minute charge heterogeneity analysis method and performance improvements that provide automated analysis of 100 samples at a time.

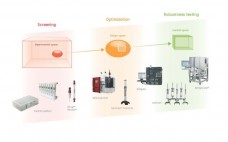

How to Achieve Greater Efficiency in Biopharmaceutical Process Development

Read about GE Healthcare Life Sciences’ support from efficient process development to production through products, consulting services as well as specific, individual collaborations. “Our aim is to help bioprocessing teams to map the optimal plan to transform an idea into results, with greater flexibility and confidence, reducing time and costs along the way. Our global team of bioprocessing experts will support you in the optimization and troubleshooting of existing unit operations or in the design of efficient and cost-effective processes…

Cookie Cutter Proteolysis: Achieving Reproducible, Efficient Digestions for Proteomic Workflows

Cookie Cutter Proteolysis: Achieving Reproducible, Efficient Digestions for Proteomic Workflows  Protein sample preparation workflows for mass spectrometric analysis that involve proteolysis are often labor-intensive, time consuming and user dependent. These workflows often involve digestion, solid phase extraction, drying, and re-suspension prior to reversed phase separation into the mass spectrometer. The introduction of variability at many of these steps hinders discovery initiatives as well as the ability to convert these discoveries into viable assays.  Recently, an automated protein digestion…

Scale-Up of Adherent Vero Cells Grown on Cytodexâ„¢ Microcarriers Using ReadyToProcess Equipment

In cell culture-based vaccine production, scale-up of adherent cells is challenging. This study shows a process for scaling up adherent Vero cells from static cell factories to influenza production at 50 L scale using WAVE Bioreactorâ„¢ systems and ReadyToProcess singleuse equipment. Vero cells were grown to high cell density on Cytodex microcarriers in 10 L working volume. The cells were detached with trypsin and used to seed a 50 L production culture with the same microcarrier concentration. The cells were allowed to reattach and grow on the new microcarriers in a larger Cellbagâ„¢ bioreactor chamber. Cells were subsequently infected with influenza virus. The results show a repeatable scaleup procedure.