This webcast features: Troy Ostreng, Senior Product Manager, Colder Products Company In state-of-the-art biopharmaceutical manufacturing, you’re challenged to engineer and operate processes that are robust, reliable and repeatable. Building on the inventiveness of CPC and its AseptiQuik® Series Connectors, the leader in single-use connection technology, the company’s new MicroCNX™ Series Connectors provide a modern alternative to the tube welding process. In this presentation, CPC’s biopharma senior product manager, Troy Ostreng highlights how this new category of aseptic, sterile micro-connectors provides…

Author Archives: BPI Contributor

The Importance of Raw Materials in Viral Vector Manufacturing

Focus on transfection reagent. The rapid advance of so many gene therapy candidates is creating several key challenges. There is a strong need for higher viral vector yields and scalable manufacturing to reduce costs of gene therapy for affordable patient treatment, all of that while meeting cGMP compliance to ensure patient safety which, push comes to shoves, always comes first. A critical step for viral vector manufacturing is sourcing of raw materials to maximize production yield while meeting quality requirement.…

Successful Drug Development with Synthetic Lipids: Critical Aspects and Strategies

Currently gaining enhanced momentum due to their vital role in the development of vaccines against COVID-19, lipid-based formulations and lipid nanoparticles have shown a lot of promise in drug development and delivery particularly because of their ability to enhance active pharmaceutical ingredient (API) stability by protecting the API from immune response, proteases and other factors; boost the solubility and bioavailability of drugs with poor water solubility; passively target inflamed or tumor tissues due to their leaky vasculature, known as the…

A Guide to Accelerating Cell Line Development for Commercial Production

Effective, high-quality cell line development (CLD) is essential for success in the commercialization of protein biologics, but there is no one right way to tackle it. Some companies have extensive in-house capabilities and look for reliable equipment suppliers to help streamline early-stage development and enable a smooth transition to manufacturing. On the other end of the spectrum, certain companies need a fully outsourced solution to provide cell lines, products, and experienced professionals to oversee the entire CLD project. And others…

Commercial Scale Insect Cell Culture: Opportunity and Challenges in a CHO Centric World

This webcast features: Sharyn Farnsworth, Principal Scientist and Upstream Process Development-Cell Culture Group Leader, FUJIFILM Diosynth Biotechnologies A strategy for scale up and manufacture of a recombinant protein from Insect Cell Culture (ICC) using a Baculovirus Expression Vector System (BEVS) should be mapped out during the earliest stages of process development. The challenges of recombinant protein expression using ICC/BEVS production systems are different from more commonly used expression systems such as Chinese hamster ovary (CHO) and few vendors have the…

Reagents Matter – Osmolality Testing in Gene Therapy Manufacturing

Osmolality testing provides a versatile measure of solute concentration that is an important consideration in the manufacture of gene therapies. This white paper discusses how monitoring osmolality of media during upstream viral vector production and reagents during downstream purification processes can influence quality of the final product. The dependence of multiple biological processes on osmolality, coupled with the usefulness of its measurement in vector quality control, means that osmolality testing is a powerful method to support a high yield of…

Guidelines for Developing a High Cell Density Cryopreservation Process

Biopharmaceutical manufacturers are leveraging several approaches to intensify processes with a goal of improving efficiency and productivity and reducing costs — all while ensuring the highest quality standards. The upstream workflow offers several opportunities to apply next generation technologies and methods to achieve these important goals. In this white paper we discuss integration of high cell density cryopreservation (HCDC) in the seed train and explore key considerations for developing a cryopreservation process including choice of cryoprotectant and freezing techniques.

Top Considerations for the Development of Inhaled Biologics

This webcast features: Ashleigh Wake, Business Development Director, Intertek Pharmaceutical Services Inhaled and nasal biologics continue to grow in importance as advantages presented both by targeted delivery to the lung and systemic delivery for other diseases or treatment pathways are driving this increased attention. In this webinar, Ashleigh Wake describes the top development considerations for inhaled or intranasal biologic analytical development. These include the need to meet regulatory requirements of ICH Q6B for a well characterized biologic as well as…

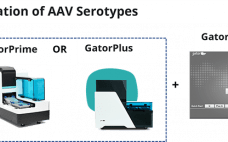

GatorTM AAVX Probes for Rapid and Label-free Quantitation of AAV Serotypes

Adeno associated virus (AAV) capsids are a leading modality for in vivo gene delivery. Complete and precise characterization of capsid particles, including capsid and vector genome concentration is necessary to safely and efficaciously dose patients. In virus development and production, it is important to determine the virus concentration at different stages of the process, optimize the clone used and obtain best production yields. Easy, rapid and cost effective quantitation methods are critical to achieve above goals. The Gator AAVX probes…

Ask the Expert: Facilitating Process Development Using a Microfluidic Perfusion Bioreactor

Suitable scale-down perfusion systems generally have been unavailable for process development (PD) activities. Some commercially available systems require daily media exchanges. No such system performs in a way that accurately represents large-scale perfusion, and none maintains sufficiently high cell densities. Kevin Lee (cofounder of Erbi Biosystems) joined BPI on 4 May 2021 to explain how his company’s Breez bioreactor system integrates all the functions of a stirred-tank reactor (STR) into a compact format that can facilitate PD, enabling one person…