IntelliCyt, a Sartorius Company, and a leading provider of integrated platforms that accelerate drug discovery, antibody screening and immuno-oncology research today announced the launch of the Cy-Clone Plus assay system for ranking and selection of clones for cell line development using the iQue Screener PLUS platform. A key factor in reducing the production costs of biopharmaceuticals is the development of cell lines producing a high yield of product. The Cy-Clone PLUS selection strategy is designed to identify clones that are…

Author Archives: BPI Contributor

Sartorius Acquires Software Company Umetrics and Closes the Acquisition of Essen BioScience

Sartorius, a leading international partner of the biopharmaceutical industry and research laboratories, today acquired through its subgroup Sartorius Stedim Biotech the company MKS Instruments AB (Umetrics) based in Malmö, Sweden. Umetrics is a leading specialist in data analytics software for modeling and optimizing biopharmaceutical development and manufacturing processes. Umetrics has already been cooperating with Sartorius for around five years and, in 2017, plans to generate full-year sales revenue of around U.S. $15 million and a significant double-digit operating profit margin.…

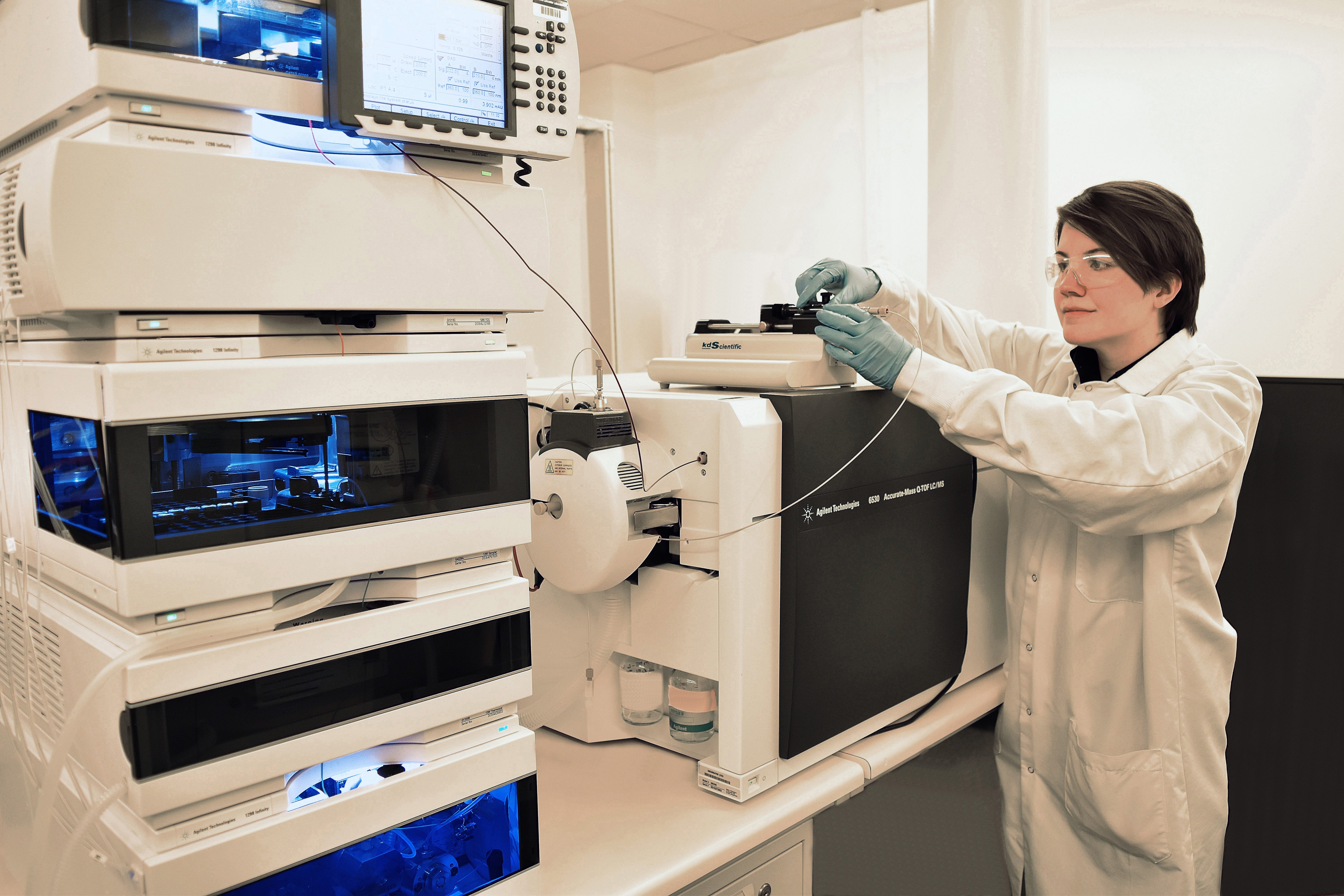

Case Studies Using Mass Spectrometry to Characterize a Protein-Hapten Drug Substance

Clients often come to us with protein conjugation process needs that can require development of new and innovative methods to assure process validation for conformance manufacturing. Our staff utilizes state-of-the art technologies and instrumentation for a wide range of protein drug manufacturing challenges. These scientists provide the expertise and experience needed to develop accurate and highly reliable assay methods designed specifically to assure successful conformance manufacturing of their protein-hapten or protein-drug conjugate. This white paper illustrates just one example of…

Nile Polymers Inc. Offers New High Performance Cable Ties Made from Kynar Flex® PVDF

Nile Polymers Inc., located in Centerville, UT, has recently commercialized a series of cable tie sizes based on Arkema Inc.’s Kynar Flex® PVDF under the trademark Strong-Ty™. These injection molded cable ties are readily available in 4-inch and 8-inch lengths and are manufactured and packaged in a clean room following ISO 13485:2016 procedures. Strong-Ty™ cable tie flexibility can be tailored simply by changing the chosen grade of Kynar Flex® PVDF. Kynar Flex® resins offer a multitude of desirable properties that…

Use of the ambr®250 in Combination with High-Throughput Design and Analysis Tools for Rapid, Scalable USP Development

There have been many recent advances in high throughput (HT) technologies for upstream development, enabling processes to be developed in a fraction of the time compared with conventional methods. However, when applying this technology to biotherapeutic drug development, the suitability of the systems for developing large scale manufacturing processes and meeting regulatory demands needs to be demonstrated and ensured. Inclusive approaches encapsulating platform expression systems and fermentation technologies, parallel bioreactor systems, high throughput analytics and sophisticated design and data handling…

Welcome

An international group of experts met last year and exchanged their latest findings in bioprocessing technology at the Sartorius Stedim Biotech Upstream and Downstream Technology Forum, held at Sartorius College in Göttingen, Germany. This conference continues a more than decade-long tradition of bringing together leaders in bioprocess development and biomanufacturing operations from the world’s leading biopharmaceutical companies to explain how they are addressing the most important industry challenges. Although conference presentations were divided as related to either upstream processing, downstream…

MilliporeSigma Introduces Mobius® MyWay Portfolio for Customized Single-Use Assemblies

MilliporeSigma, a leader in single-use technology, today launched an industry first-the Mobius® MyWay portfolio, a program that allows more flexibility, better supply predictability and shorter lead times for more efficient and safer drug manufacture. “We have the industry’s only comprehensive single-use solution, giving customers three different ways to create customizable assemblies,” said Andrew Bulpin, Head of Process Solutions Strategic Marketing & Innovation, MilliporeSigma. “This is critical to customers from contract manufacturing organizations to big pharma, whose biggest challenge is getting…

Thermo Fisher Scientific and the Cell and Gene Therapy Catapult Collaborate to Optimize Advanced Therapy Supply Chain

To help address the challenges surrounding supply chain management for cell and gene therapy around the globe, Thermo Fisher Scientific, the world leader in serving science, today announced a collaboration with the Cell and Gene Therapy Catapult (CGT Catapult) to provide developers with both the manufacturing capability and distribution, logistics, and storage capacity needed to create a seamless supply chain to accelerate cell and gene therapy development and commercialization. As part of the collaboration, Fisher BioServices will expand its CryoHub…

Millipore Express® High Area Filters for Processing Feed Streams with High Particulate Levels

MilliporeSigma’s Millipore Express® high area cartridges and single use capsules are ideal for feed streams with high levels of particulates, such as cell culture media and protein solutions. These new high area filters help ensure product safety, efficient and effective processing and optimum yield for demanding drug production processes. The Millipore Express® high area cartridges and capsules combine fast flowing polyethersulfone (PES) membranes with an M-pleat pattern. This design provides up to twice the surface area of a conventional filter,…

Extractable and Leachables Studies: Designed and Performed to Meet all Intended Needs

Since the FDA released their Container Closure Systems for Packaging Human Drugs and Biologics guidance in 1999, evaluation of final packaging components for extractables and leachables has become the expectation within the industry. Additionally, the increase in the use of single-use systems in manufacturing has drawn scrutiny as another potential source of extractables and leachables. Extractables are compounds that can be extracted from a product contact material under exaggerated conditions such as elevated temperatures, extended storage times, or exposure to…