This webcast features: Nigel Shipston, Director, Program Design, FUJIFILM Diosynth Biotechnologies A strategy for the development and scale of bioprocesses should be assessed at the earliest of stages. There are different challenges depending on the molecule and expression system. This webinar is designed to address some of the areas of consideration for successful development of bioprocesses for biologics and gene therapies. At the end of this webinar, you will be able to do a self-assessment to answer some critical questions:…

Author Archives: BPI Contributor

High Titer Recombinant Lentivirus and Adeno-associated Virus Production for Therapeutic Applications

Increase your recombinant lentivirus and adeno-associated virus (AAV) production with a novel transfection formulation, TransIT-VirusGEN® Transfection Reagent, specifically designed for large-scale virus production to support gene and cell therapies. This poster highlights TransIT-VirusGEN® for use in adherent or suspension cell culture platforms along with enhancers that significantly increase functional virus titers over PEI based formulations. Testing was performed with multiple serum-free media formulations and examined using different plasmid DNA concentrations to better address compatibility within various workflows. Download the poster…

Risk and Lifecycle Management for Biopharma Operations

By working with the best biopharmaceutical companies for over a decade, 4Tune Engineering (4TE) has built a portfolio of services that enables companies to address current-century challenges. The biotechnology industry needs to address advanced therapies and personalized medicines and deliver explicit patient outcomes. Biologics today fall into four categories: monoclonal antibodies (MAbs), biosimilars, advanced therapeutic medicinal products (ATMPs), and cell and gene therapies (CGTs). Consequently, we can ask whether our manufacturing science and technology (MSAT) approaches are up to the…

Making Media a Priority: An Interview with Susan Riley of Advanced Bioprocessing

Susan Riley is vice president and general manager of Advanced Bioprocessing. It’s been a year since Thermo Fisher Scientific’s acquisition of the Advanced Bioprocessing business from Becton Dickinson (BD). Why did Thermo Fisher see the Advanced Bioprocessing (AB) business as a good fit with its life-science offerings? AB has a significant portfolio in premium supplements for cell culture and microbial fermentation. The AB business was seen as a good fit for several reasons: It goes hand-in-glove with Gibco media, for…

Ask the Expert: Scalable Purification Strategies for Viral Vectors and Vaccines

Viruses and virus-like particles (VLPs) raise unique challenges for downstream recovery and purification. In an Ask the Expert webinar on 19 September 2019, Mark Snyder (R&D applications manager of process chromatography at Bio-Rad Laboratories) discussed purification methods engineered to perform at manufacturing scales. Offering case studies featuring Nuvia resin and CHT Ceramic Hydroxyapatite chromatography support, Snyder emphasized that scalable media can help companies optimize downstream operations and address evolving manufacturing requirements. Snyder’s Presentation Tremendous growth in markets for vaccines and…

Ask the Expert: Risk-Based Approaches to Software Systems Compliance

Software risk management often seems synonymous with extra documentation. But during a 17 October 2019 Ask the Expert webinar, Martin Laferriere (director of information technology services at Avid Bioservices) explained how a thoughtful risk- assessment process at early project management stages can optimize software system validation efforts. Laferriere illustrated the benefits of developing strategic structures for documenting system use, hazards, and testing requirements. Such structures can help biomanufacturers clarify what records and functionalities they need to concentrate on to remain…

Ask the Expert: Rapid Virus Quantification in the Development and Manufacture of Emerging Therapies

The development and manufacture of emerging viral therapies is highly dependent upon accurate infective virus titers as well as total particle counts. But traditional quantification technologies have not kept pace with the needs of the viral vector market. Quantification methods based upon infectious particle counts can easily underestimate total particle counts. Indirect measurements such as enzyme-linked immunosorbent assays (ELISAs) and quantitative polymerase chain reaction (qPCR) are prone to overestimating the number of virus particles because they measure virus components to…

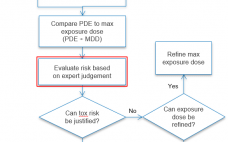

Case Study in Conducting Chemical Safety Assessments for Single- and Multi-Use Manufacturing Components

This webcast features: Dr. Sherry Parker, Senior Director, Regulatory Toxicology and Technical Services, WuXi AppTec Extractable and leachable studies of single- and multi-use manufacturing components should be followed up with a chemical safety assessment to understand the chemical risks based on the toxicity of the chemical, the dose and the exposure duration of the drug product, and the patient population for its intended use. This case study will illustrate considerations when conducting a chemical safety assessment, the pitfalls of having…

Why Characterizing Protein Stability Matters For Drug Development

Characterizing a protein’s stability provides key insights into the expression, signaling, and regulatory roles of a molecule. This is necessary for numerous applications from understanding the molecular basis for certain diseases to ensuring more effective drug development. Ultimately, the stability of a protein is closely tied to its functional activity. Whether you’re just starting to learn about characterizing protein stability or you’re looking for a refresher, this guide has some helpful tips to answer why it’s important, what technologies are…

Bioprocess Intensification – Fast, Flexible, and Efficient Solutions

Propelled by single-use systems (SUSs), biopharmaceutical companies are approaching the ideal of continuous bioprocessing. In addition to improving process integrity and decreasing production costs, SUSs have enabled exciting ways to configure, operate, and evaluate manufacturing steps. Sensitive process analytical technologies (PATs) and discriminating data analysis platforms are supplementing those developments, helping process engineers and operators to study and modify workflows in unprecedented ways. The goal now is to intensify: to apply increasingly nuanced process knowledge and growing technological capability in…