This webcast features: Andrew Hanneman, Scientific Advisor, Charles River Laboratories One of the major challenges to developing successful biopharmaceutical products is understanding and characterizing potential impurities. Finding the source and magnitude of these impurities allows us to minimize and remove them during the manufacturing process to create a safe and effective drug. Development also needs to include supporting stability and forced degradation studies to ensure long-term safety and efficacy. Some impurities, such as protein degradants, host cell proteins, and various…

Author Archives: BPI Contributor

New Data: A Better Way to Run CHO Cell Culture Experiments

This webcast features: Deborah Pascoe, PhD, Vice President of Operations, Culture Biosciences The bench-scale bioreactor has been the workhorse of Chinese hamster ovary (CHO) cell culture process development for decades. However, running benchtop bioreactors requires significant resources, infrastructure, and staffing. Tubing assembly, sterilization, calibration, and other setup activities can take hours to days. Tear down, cleaning, and deactivation are similarly burdensome. There are potentially large associated costs to prepare or purchase media, carry seed trains, and maintain facilities. Most critically,…

Transfection Reagents for Cell and Gene Therapy

Polysciences offers high-quality, R&D and cGMP grades of transfection reagents for the smooth transition from process development through clinical trials and commercial manufacturing of viral vectors/protein. Polysciences R&D grade PEI MAX has been used by academic and industry customers for over a decade and is one of the most cited transfected reagents. A few years ago Polysciences launched an easy to use liquid version of PEI MAX which is called Transporter 5 focusing on increased customer convenience. Both PEI MAX…

Integrated mRNA Production Process from E. coli to Highly Purified mRNA

This webcast features: Aleš Ĺ trancar, Managing Director, BIA Separations, a Sartorius Company In vitro transcription (IVT), the enzymatic process used for the production of mRNA vaccines, differentiates itself from biological fermentation processes by the need for linearized plasmid DNA. The linear isoform is produced with restriction enzymes from open-circular and supercoiled plasmid DNA. Employing a traditional pDNA manufacturing process, which removes linear and open-circular isoforms, will reduce production yield. However, when plasmid DNA and mRNA are treated as a single…

Lentiviral Vector Platform Generation: Increase Titer and Yield with Greater Predictability

This webcast features: Xin Xin, Group Leader, Small-Scale Upstream Process Development, and Senthil Kumar Kuppuswamy, Associate Principal Scientist, Downstream Process Development, WuXi Advanced Therapies The field of cell and gene therapies has expanded rapidly in the past several years. Lentiviral vectors have been in great demand as gene carriers in this field, especially for ex vivo gene therapies. However, large-scale lentiviral vector production still remains a significant challenge. WuXi Advanced Therapies has worked with Lentivirus since 2015 and it launched…

Improving and Intensifying Vaccine Purification By Implementing Affinity Chromatography

This webcast features: Zoltan Gulyas, Field Applications Specialist, Thermo Fisher Scientific Vaccines are well-established tools in the fight to eradicate infectious diseases. Over the past few decades, vaccine production has advanced significantly, largely by the introduction of new molecule modalities. However, these new types of vaccine candidates often require multiple chromatographic steps to obtain the desired level of purity. Developing an efficient purification process using the classical surface chemistries such as ion exchange and hydrophobic interaction requires significant amounts of…

Announcing the Winners of the 2020 BPI Readers’ Choice Awards

In the fall of 2020, BPI premiered its Readers’ Choice Awards program. Concentrating on articles published from September 2019 through June 2020, with rankings based on digital engagement, BPI staff identified the most popular articles within each of six categories of bioprocess coverage. You ranked those articles in terms of innovativeness, applicability, and presentation. We’re pleased with the turnout and delighted now to congratulate the winners, who were announced first online. Analytical Award BPI congratulates the winner of our Readers’…

Ask the Expert: Enabling Digital Chromatogram Review to Streamline Column Evaluations

Chromatogram review enables evaluation of packed-bed chromatography processes. Typically, that method entails paper-based, qualitative comparison of a profile obtained during a run with another from a reference batch. Such a protocol can be time consuming, resource intensive, and susceptible to operator error. Martin D. Jensen (senior engineer at Fujifilm Diosynth Biotechnologies, FDB) delivered an “Ask the Expert” presentation on 20 October 2020 to describe advantages that his company gained by transitioning from paper-based to digital chromatogram review. Jensen’s Presentation Chromatogram…

Ask the Expert: Revealing Cell Secrets Using Optical Sensors in Upstream Processing

Upstream operations can benefit significantly from real-time, in-line testing of cell-culture conditions. Yet as Jake Boy (senior application scientist at Scientific Bioprocessing Inc., SBI) observed in his 5 November 2020 “Ask the Expert” webcast, traditional electrochemical probe sensors do not perform well in T-flasks, shake flasks, Petri dishes, and microfluidics devices. Boy described how fluorescence-based optical sensors can glean valuable data from small culture devices, assisting with research into cellular growth. SBI’s Presentation Boy began by highlighting successful applications of…

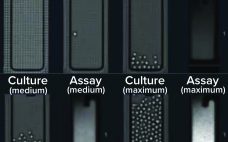

Ask the Expert: Derisking INDs with Unrivaled Monoclonality Assurance in Cell-Line Development

On 1 December 2020, BPI presented an “Ask the Expert” webinar with Tanner Nevill (vice president of program management at Berkeley Lights). Monoclonality assurance is a central regulatory requirement for all cell lines producing biologic therapies. Well-plate imaging is the “gold standard” for confirming that a cell line originates from a single cell, but it is labor intensive and prone to errors in the form of “ghost cells” and debris that look like cells. Using the Berkeley Lights Beacon system, cells…