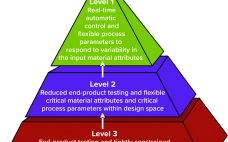

Process control enables biomanufacturers to ensure that operating parameters are within defined specifications. A control strategy should be established during early stages of process development while process and product performance are being defined using risk-based methods such as quality by design (QbD) and process analytical technologies (PATs). Confirming process control as an essential part of product development creates greater process knowledge and understanding and provides the first steps toward process optimization. By understanding how process performance relates to product quality,…

Author Archives: Christoph Herwig

Data Science, Modeling, and Advanced PAT Tools Enable Continuous Culture

Bioprocesses traditionally use (fed-)batch cell culture processes for production of recombinant proteins and therapeutics. In batch bioprocessing, material flow is discrete, with a hold step between two unit operations, and product is harvested only once for each unit operation. Batch processes have been studied extensively and optimized through numerous advancements in experimental design (1, 2), monitoring (3–5), measurement techniques (6–9), and control strategies (10–12). However, such processes require large facility footprints for equipment (13) as well as sterilization, load, and…

Online Monitoring of CHO Cell Culture

Mammalian cell culture processes are very important in the production of recombinant proteins such as vaccines, antibodies, and pharmaceuticals for clinical applications. The physiology of mammalian cells is highly sensitive, leading to the need for sophisticated process technologies. A reliable sensor set-up is required to control major process parameters such as pH, dissolved oxygen, carbon dioxide, cell density, and feed rates. If such set points are not controlled tightly, then product quality and quantity might be altered. In addition, a…