Careful consideration of lot size is crucial for multiyear success of a cell therapy business. RoosterBio’s product design and acceleration business works with the company’s customers to help make plans that are appropriate for their stages of product and clinical development. We use the following major considerations in creating a sound multiyear strategy with intermediate milestones: Understand what the future looks like and work backward Use reasonable to conservative assumptions to estimate a range of needs Invest in the right…

Author Archives: Jon A. Rowley

The Need for Adherent Cell Manufacturing: Production Platform and Media Strategies Drive Cell Production Economics

Most commercial biopharmaceuticals originated from academic research laboratories and start-up development laboratories. Despite such products having differences in modalities and targeted disease indications, and whether their target patient populations are relatively small or approaching blockbuster status, at a key point in development, biopharmaceutical production must scale up from laboratory to commercial production. That movement from research to development and then to manufacturing forces attention on economics and speed to market, and it drives innovative approaches to producing biopharmaceutical cell compositions…

Downstream Technology Landscape for Large-Scale Therapeutic Cell Processing

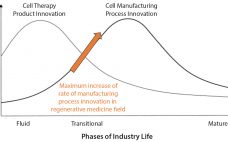

The cell therapy industry (CTI) is poised to grow rapidly over the next decade, treating millions of patients and generating annual revenues into the tens of billions of US dollars (1, 2). To meet that high-growth demand, large CTI system manufacturers (e.g., Corning, Nunc/Nalgene, and GE Healthcare) and leading contract manufacturing organizations (CMOs, such as Lonza) are developing and integrating new upstream technology platforms such as gas-permeable membranes and microcarrier-based bioreactors to significantly increase therapeutic cell culture productivity. As those…

Cell Therapy Bioprocessing

The past 15 years have seen approval and commercialization of the first cell-based therapeutics, including cartilage repair products; tissue-engineered skin; and the first personalized, cellular immunotherapy for cancer. Those successes are outnumbered, however, by all too common product failures. Notable failures can be attributed to commercial concerns such as high cost of goods (CoGs) and technical hurdles such as inadequate characterization, high process variability, and loss of product efficacy when manufacturing is scaled up (1).…