To achieve good growth of microorganisms and high yields in protein expression, the following factors in fermentation are important: medium, gas ![]()

Fermentors for research and development have to meet very high standards for flexibility so that they can be easily adapted to the requirements of a wide range of microorganisms and process conditions. For that purpose, modular fermentation systems were developed, consisting of single modules such as drive, fermentation vessel, analytical instrumentation, stirrer, foam separator, ventilation, and so on. This allows for individual assembly and upgrades.

Fermentors for research and development have to meet very high standards for flexibility so that they can be easily adapted to the requirements of a wide range of microorganisms and process conditions. For that purpose, modular fermentation systems were developed, consisting of single modules such as drive, fermentation vessel, analytical instrumentation, stirrer, foam separator, ventilation, and so on. This allows for individual assembly and upgrades.

metabolism, temperature, pH, and pressure.

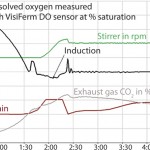

The concentration of dissolved oxygen (DO) in medium (proportional to the pO2 value, which is the partial oxygen pressure that is determined as DO) is an important parameter of gas metabolism. The Hamilton VisiFerm optical DO sensor was tested for four months monitoring this parameter.

The Measurement SiteThe rate of the stirring speed and air flow starts with a default value set by the process control system (PCS). During fermentation, the oxygen concentration in medium declines. The PCS adjusts stirring speed and air flow to keep oxygen concentration at 50% saturation.

User Benefits of VisiFerm Optical DO Sensor

- Long sensor lifetime under frequent sterilizations

- Maintenance free: no exchange of electrolyte, robust sensor cap

- Ready to use: no waiting time for polarization

- Highly stable DO readings after sterilization

As shown in Figure 1 , the entire fermentation process lasts only about five hours. At the end of fermentation, the content of the fermentor is cooled and centrifuged. The empty fermentor with the VisiFerm DO sensor still installed is filled with 0.1 M KOH and dead autoclaved (sterilized) at 121 °C for 25 minutes. Subsequently, it is flushed with deionized water. This procedure is very demanding on the DO sensor because of the many cleaning and sterilzation cycles per week.

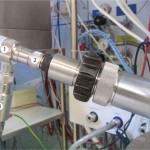

FIGURE 2: Xpansion bioreactor in operating mode, mounted on the iLine holographic microscope; 1: ARC Wi sensor adaptor, 2: VisiFerm DO sensor, 3: Fermenter, 4: VisiFerm D4 power adapter

Improvements with

VisiFerm DO

The user handling of VisiFerm DO sensor is much easier than that of an electrochemical Clark sensor. The frequent exchange of electrolyte and membrane caps is unnecessary, and long wait times are eliminated because there is no polarization needed. The sensor is ready for use immediately (Figures 2 ,3).

Furthermore, the VisiFerm DO sensor shows more stable readings after the frequent sterilization cycles shown in this application. With the help of the VisiFerm D4 power adapter, the VisiFerm DO sensor was run in ECS mode without any technical changes to the existing PCS (In ECS mode, VisiFerm DO sensor emulates the electrical behavior of an electrochemical DO sensor).

Christian Miscenic works in technical support and fermentation at F. Hoffmann-La Roche Ltd., CH-4070 Basel; www.roche.com ; Contact for Hamilton Americas and Pacific Rim: 4970 Energy Way, Reno, Nevada 89502, 1-775-858-3000; fax 1-775-856-7259; sales@hamiltoncompany.com; Contact for Hamilton Europe, Asia, and Africa: Via Crusch 8, CH-7402 Bonaduz, Switzerland, 41-81-660-60-60. fax 41-81-660-60-70;

contact@hamilton.ch; www.hamiltoncompany.com

.