North American demand for aseptic filters and single-use bags drove Sartorius to expand its facility in Yauco, Puerto Rico.

German bioprocessing supplier Sartorius began expanding its Yauco production and distribution center in 2016 and has invested more than US$100 million (€86 million), according to spokesperson Timo Lindemann.

The investment brings Sartorius an additional area covering nearly 190,000 square meters – around two million square feet – he told BioProcess Insider.

“A focal area of investment will be on expanding aseptic filter and bag manufacture, which we began in 2016. In addition, we are building a membrane casting machine.”

Sartorius has had a presence at Yauco since 1982, and has steadily increased capabilities at the site. This latest expansion, which doubles production of single-use bags and membrane filters for the biomanufacturing industry, was driven by strong demand in the US market, Lindemann said.

“In view of our strong growth in North America, we not only pulled forward this investment compared with our original plans but also increased the scale of this project. Therefore, capacity of the Yauco plant will be doubled.”

Puerto Rico

The (bio)pharma industry has been a prominent investor in Puerto Rico since the 1960s, encouraged by low taxes and its direct access to the US market. As well as drug manufacturers like Pfizer and J&J, service firms and vendors, such as Sartorius, have made their home on the island.

“Here, we are close to our customers: Many of the major drug manufacturers produce in Puerto Rico,” Lindemann told us. “In addition, we have many excellent long-term employees there and high production quality.”

More than 450 people work at Sartorius in Yauco, he continued, adding the region provides a “highly conducive business environment as well as a favorable investment climate.”

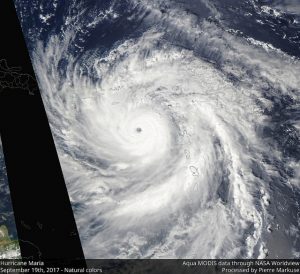

Hurricane Maria

Last year, hurricane Maria caused catastrophic damage and a major humanitarian crisis, leaving much of the island unreachable and without electricity.

“Thanks to the high construction standards at the Yauco site, existing buildings and those under construction suffered only minor damage that was repaired within a short time,” Lindemann said.

“However, heavy general infrastructure damage to roads, power system, airports etc. prevented deliveries from the plant for around four weeks. In the future, our manufacturing operations will focus more strongly on standard products that can be stored on the US mainland to reduce any future disruptions in the supply chain.”