The cell therapy industry (CTI) is poised to grow rapidly over the next decade, treating millions of patients and generating annual revenues into the tens of billions of US dollars (1, 2). To meet that high-growth demand, large CTI system manufacturers (e.g., Corning, Nunc/Nalgene, and GE Healthcare) and leading contract manufacturing organizations (CMOs, such as Lonza) are developing and integrating new upstream technology platforms such as gas-permeable membranes and microcarrier-based bioreactors to significantly increase therapeutic cell culture productivity. As those upstream technologies mature, following the path that protein therapeutics took decades ago, cell yields are expected to increase to hundreds of billions to trillions of cells per lot (3). Increasing the number of cells per lot raises harvest volumes from current tens of liters to more than 100 L in one to five years (a conservative estimate) and up to 1,000 L over the following 10 years. Such large-quantity cell harvests will need to be concentrated, washed, formulated for cryopreservation, filled into final containers, frozen, and stored. Those downstream processing (DSP) steps are the most critical unit operations in biotherapeutic manufacturing, for which product typically is at high concentration. Therefore, a small variation can have significant impact on product quality and/or recovery.

Currently in the CTI, however, little attention is being assigned to scalable DSP technologies. In the mid-1990s, when production titers of monoclonal antibodies (MAbs) were as low as ~100 mg/L, DSP groups were pressed to achieve significant recoveries with minimal loss of product and thus keep manufacturing costs to a minimum (4). Bioreactor MAb expression has increased to more than 10 g/L, and DSP groups are strained, requiring dilution of harvested medium just to process such high-titer yields. Similarly, as lot-size requirements of therapeutic cells increase to address escalating market needs, DSP will experience similar bottlenecks unless the industry strategically plans and develops new, scalable technologies (5).

The CTI has an opportunity to learn from protein processing and anticipate DSP bottlenecks by proactively developing technologies to address future scales. CTI companies are in a unique position to take their industry to the next level of scalable manufacturing by using functionally closed, single-use technologies that can process hundreds of liters of cell suspension in a single batch. Here, we propose some CTI downstream technology requirements.Additionally, we examine traditional technologies used in blood processing and compare them to newly developed, scalable downstream bioprocessing technologies in terms of efficiency, scalability, degree of automation, cost, and applicability to large-scale volume reduction and washing of therapeutic cells.

Product and Process Requirements

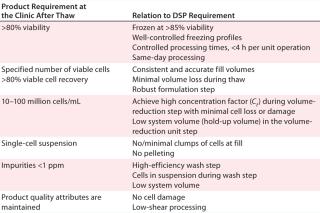

A thorough technology evaluation is best performed only with a comprehensive knowledge of product requirements that in turn dictate DSP requirements (Table 1).

When a cell therapy product dose is thawed at a clinic for administration, it is expected to have a minimum acceptable viability of 70% (ideally >85%), and clinicians will ideally recover >80% viable cells. To achieve such high viability for product doses, cell viability drops should be monitored and controlled in each downstream unit operation after cell harvest.Low-shear volume reduction and wash systems will also need to be designed, and controlled-rate freezing operations with uniform freezing profiles will be required as well. Controlling processing times for all downstream steps to a minimum is important to help ensure that harvested cells can be cryopreserved on the same day (to maximize cell health). Table 1: Typical product requirements and their relationship to downstream steps

Table 1: Typical product requirements and their relationship to downstream steps ()

Additional DSP requirements should be considered: e.g., achieving a broad range of cell concentrations (10 million to 100 million cells/mL) and low impurities (high residual clearance). Those translate to key design requirements for the volume-reduction and wash steps to have low system volume and reach a high concentration factor (Cf), keeping cells in suspension so that all of them are washed efficiently.

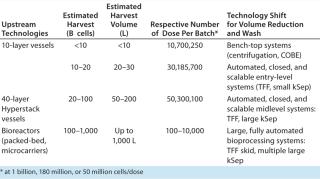

As these DSP technologies are scaled up and used in late-stage clinical and commercial production, disposable process analytical technologies (PAT) will enable real-time data collection and decision making so that processes can be continuously monitored and product quality controlled as guided by the FDA’s PAT framework. Furthermore, increasing lot sizes will be an economic driver to close the system and minimize the risk of lot failure due to contamination. Scaling up lot sizes in cell number or doses per manufacturing batch should also be considered. Both have a significant impact on DSP requirements and thus the technology required to meet increased lot sizes (Table 2). Bench-top systems are sufficient to process culture volumes that are <10 L. However, culture lots that are >20 L with yields >10 billion cells and >100 doses are likely to require closed and scalable technologies such as tangential-flow filtration (TFF) or continuous-flow centrifugation.

As cell yields scale from tens to hundreds of billions (with doses reaching thousands per lot), automated TFF skids or large-size continuous centrifuges are likely to be required for volume reduction and washing of cell products. Table 2: Shifting lot sizes requires new DSP technology development in the cell therapy industry

Table 2: Shifting lot sizes requires new DSP technology development in the cell therapy industry ()

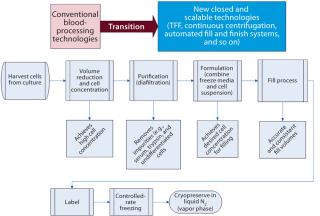

Figure 1 illustrates DSP steps of a typical cell therapy manufacturing process. Volume reduction and cell-washing steps usually follow harvesting in cell therapy manufacturing. During volume reduction, harvested cells from upstream processes are concentrated to achieve a >40-fold concentration factor. Once cells a re concentrated, they are washed into a purifying buffer to reduce the level of unwanted residuals such as serum and trypsin. The concentrated and washed cells are then formulated with a cryopreservation buffer. During that step, cell concentration is adjusted so that the final filled product dose delivers a specified quantity of cells. The formulated bulk cell suspension is then filled into containers. During that filling step, a highly accurate and consistent method (and system) should be used to deliver a specified volume of cell suspension to each vial. The resulting product doses are then cryopreserved using controlled-rate freezers (CRF) and stored in the vapor phase of liquid-nitrogen dewars. Each unit operation has unique process requirements that depend on total harvest yields, target cell dose and concentration, and total product doses per lot.

Figure 1: ()

Process Challenges at Hand: Expansion and recovery of therapeutic cells in a scalable culture system should be a well-regulated process that minimizes contamination risk, prevents product degradation, and maintains product functionality. High-purity cell products are important because they consist of human cells that are intended for implantation, transplantation, or infusion into a human patient. So they should meet specific criteria to be used as therapeutics.

When a cell therapy product is thawed to be administered at a clinic, it should have a specified minimum number of viable cells (e.g., 100 million viable cells). The viability of those cells must be high or the number of nonviable cells at a minimum (e.g., <20%). To achieve those specifications, acceptable manufacturing variability should be anticipated and accounted for during DSP steps. Many cell therapy products require a high cell dose delivered at low volume. So a major challenge for scaling DSP technology in the CTI is to manufacture and process large volumes of cells in suspension (100–1,000 L), achieving high cell concentrations and purity levels for cryopreservation before delivery to end users.

The processing to deliver accurate dosages consistently from batch to batch is problematic. Current cell therapy products for clinical trials are filled typically at a varying concentrations from less than a million cells to more than a billion cells per container. CTI fill volumes (volumes of cell suspension in final containers) can vary from 0.5 mL to 20 mL. Those wide ranges significantly affect DSP. A volume-reduction step should achieve high cell concentration, often >25 million cells/mL and in some cases ≤100 million cells/mL, with minimal product loss or change in product quality even at large scale. Such high cell concentrations can be achieved with appropriately sized systems and consideration of system hold-up volume (the minimum volume required at the end of a volume-reduction step) and the concentrations and number of cells to be processed (lot size).

A well-characterized system with low hold-up volumes can reach high cell concentrations while minimizing loss of cell viability and quality during processing. Therapeutic cell products should meet specified final product identity, potency, and purity. Most important, they must be safe to administer. Because therapeutic cells cannot be terminally sterilized (neither with sterile filtration nor irradiation), DSP developers are challenged to eliminate exogenous contaminants.

A functionally closed processing system significantly reduces the risk of exogenous contamination. Disposables can also help eliminate the threat of cross contamination with other manufacturing lots. By incorporating single-use technologies — e.g., aseptic connectors, disconnections, and sampling systems — early in the design phase, DSP groups can minimize or even eliminate contamination risks. In addition, single-use systems have been shown to save time and reduce overall cost of goods (CoGs) (6, 7).

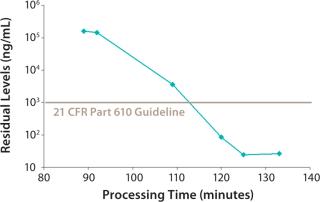

Another challenge for scale-up is efficiently washing cells to clear undesired process residuals and impurities. The Office of Cellular, Tissue, and Gene Therapies (OCTGT) at the FDA’s Center for Biologics Evaluation and Research (CBER) regulates cellular therapies as biological products. Such products must comply with relevant sections of biologics regulations in 21 CFR 610 (8, 9). Under part 610 of title 21, section 610.15 states, “If serum is used at any stage during the cell culture, its calculated concentration in the final medium shall not exceed 1:1,000,000.” Therefore, residual serum should be efficiently removed from a final product during manufacturing, targeting a final serum concentration of 1:10,000,000 to stay well above the FDA’s expectations.

A manufacturing process should be designed such that the volume of cell suspension washed should be manageable to minimize processing time (and volume of wash buffer used) while cells are in suspension, ideally as single cells. Impurities thus will not trapped between cells or irreversibly attached to them. DSP systems should promote product mixing to help ensure that dead-zone areas are eliminated from within disposable lines. Dead zones (or dead-legs) are areas in processing tubing or vessels where suboptimal mixing occurs — for example, due to stagnation or channeling. Such areas can trap impurities that eventually end up in a product.

The Technology Landscape

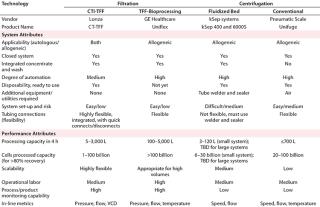

Traditional systems used for volume reduction and clarification can be categorized as either open centrifugation on a laboratory bench-top or a closed system with batch centrifugation in bags. Processes involving >10 L of cells in suspension are impractical for conventional open-centrifugation systems, which are labor intensive and increase the risk of contamination. As volumes and lot sizes increase even to modest levels — hundreds of doses or tens of liters of cell suspension — the traditional centrifuge would require multiple rounds of centrifugation with several operators, becoming time consuming and cost prohibitive. Multiple technologies adapting centrifugation, separation, and filtration principles from the blood processing field have emerged to accommodate the CTI volume-reduction and wash steps (Table 3).

Clinical blood processing equipment can significantly reduce process risks: e.g., the COBE blood processor from Terumo BCT, the Cytomate system from Nexell, the CellSaver recovery system from Haemonetics, and Carr Centritech all integrate single-use bag technology and automation.

Table 3: Comparing conventional technology on applicability in large-scale cell therapy DSP

Table 3: Comparing conventional technology on applicability in large-scale cell therapy DSP ()

The COBE 2991 cell processor is widely used in CTI manufacturing processes. Automation of this cell-processing equipment provides increased control, and it can concentrate and wash cells through disposables to prevent possible contamination. However, the volume processed in each cycle is less than a liter, profoundly restricting its scalability. To process larger volumes, a system must execute multiple cycles with long processing times, which is not acceptable for scale-up of therapeutic cells — in which processing time is critical to maintain product quality.

The Carr Centritech Cell II separation system is based on continuous centrifugation technology that could potentially concentrate ≤120 L/h depending on cell type. This equipment is not designed to perform a washing procedure readily, which is a significant drawback for CTI use. Table 3 lists blood-processing equipment that can accommodate disposables and thus were adapted early by the CTI for volume reduction and cell washing.

Scalable Technologies: The inevitable need is for new scalable DSP technologies to prevent future bottlenecks in large-scale CTI manufacturing. Current allogeneic therapeutic cell processes typically result in final harvest volumes of 20–35 L, with upstream processing (USP) being the main limitation in scale. As lot sizes increase to commercially relevant scales, USP will produce 100-L to 1,000-L harvest volumes, for which traditional blood-processing equipment for volume reduction would probably present a huge bottleneck. Scalable DSP technologies from the protein bioprocessing field may be adapted and applied to cell therapies, but extensive optimization would be required. In-depth knowledge of cell systems and process/product requirements will probably be critical to successfully optimize such systems. Scalable bioprocess technologies can be separated into filtration, size-exclusion, and continuous or counterflow centrifugation. Table 4 is not an exhaustive list of such systems, but rather an overview showing examples of filtration- and centrifugation-based systems that are considered to have significant potential for large-scale CTI application.

Table 4: Comparing new scalable technologies for cell-therapy downstream processing

Table 4: Comparing new scalable technologies for cell-therapy downstream processing ()

Filtration Technologies: In normal-flow filtration (NFF), liquid flows perpendicular to a filter membrane, typically involving disc- or cartridge-type filters alone or in series. NFF is typically applicable for sterilization and/or separating submicron molecules and are not ideal for processing large volumes of liquid that contain large-size molecules and whole cells (13, 14).

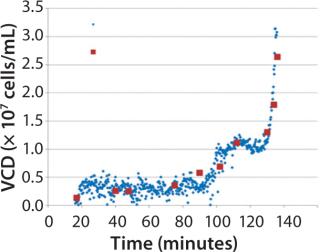

To use TFF for cell therapy processing — in which preserving high cell viabilities and biological functions is critical — engineers must rethink and redesign both the key operating parameters and systems. With a process-requirement approach and in-depth process knowledge, for example, a novel TFF process with a low shear rate driven by low TMP values has been developed. With it, high cell concentrations (60- to 100-fold) have been achieved, high viabilities (>90%) have been maintained, and cell recoveries (>85%) achieved. Additionally, cells have been washed cells efficiently by removing residuals to below 1 ppm — all while maintaining functionality and processing at acceptable permeate flow rates to reduce processing time (Figures 2 and 3).

Figure 2: ()

Figure 3: ()

For large-scale CTI applications, that system incorporates single-use pressure sensors for real-time monitoring and controlling of critical process variables such as permeate pressure and TMP. Noninvasive flow sensors can be used for enhanced and accurate fluid-flow measurements. In addition, a viable cell density (VCD) sensor from Fogale Nanotech has been optimized and incorporated that into the disposable TFF set to help ensure that critical parameters for therapeutic cell application (VCD and cell viability) can be monitored continuously and the resulting data used to make real-time process decisions.

Disposable sensors greatly enhance implementation of PAT in downstream operations and thus support a quality-by-design (QbD) approach. Because the technology is extensively used in the protein industry (12, 13), major bioprocess equipment manufacturers such as Pall, Sartorius, Millipore, Scilog, and GE Healthcare offer fully automated and disposable integrated TFF systems. Those can be reconfigured with slight modifications to accommodate CTI-specific processes catering to the unique needs of therapeutic cell products.

TFF offers a wide range of processing capacities due to the many filter sizes available. Therefore, process development costs can be low due to the small number of cells required for a meaningful run. An entry-level TFF can cost under US$30,000, whereas fully automated systems can cost more than $200,000. The cost of disposables for a medium-size TFF run (<30 billion cells) can range from $1,500 to $3,500, depending on the filter size chosen and the level of automated data collection desired from disposable sensors.

Continuous-centrifugation technologies have tremendous potential for cell therapy bioprocessing. In counterflow centrifugation, fluid flows opposite to the centrifugal force; in continuous orthogonal flow, fluid flows perp endicular to the centrifugal force. Large bioprocessing equipment such as Carr Centritech’s Unifuge system or Alfa Laval’s Culturefuge system use a continuous orthogonal flow with single-chamber or disc-stack systems. The former is a continuous fully automated, single use system that can process cell suspensions with high efficiency and low shear to prevent cell damage. The latter is a disc-stack centrifuge for much larger bioprocessing scales; however, it uses no disposables and thus requires routine cleaning and maintenance. The Alfa Laval system incorporates multiple intermittent solid discharges without a prior washing step, which is important for process streamlining to formulation and vialing. Cells are compacted in both systems, which diminishes washing efficiency (critical for CT products). Separate washing steps could be performed to remove residuals, which is undesirable because it can further reduce cell recovery by 10–30% (2, 3, 5). Furthermore, additional washes would increase the overall production time and cost for generation of therapeutic cells.

Continuous counterflow centrifugation may be more appropriate for CTI volume reduction and washing unit operations. The Elutra cell separation system from Terumo BCT and kSep technology from KBI Biopharma are both counterflow continuous centrifugation systems. Such systems allow cells to remain in suspension while supernatant and residuals are cleared. Although both share similar operating principles, the latter is a fully automated single-use system with integrated washing capability and a wide range of chamber capacity (100 mL to 6 L). The KBI system enables >80% cell recovery while maintaining cell viability at >90% and allows for efficient removal of residuals after washing — all amenable properties to the process requirement for large-scale cell therapy application. The kSep system has remarkable potential for cell therapy DSP, although the capital expense to place a system for current good manufacturing practice (CGMP) operation could range from $200,000 to $700,000. Process development costs could also be high for processing the large number of cells required for meaningful development runs because scale-down modeling is not achievable. Disposables costs for a kSep run (for <30 billion cells) would range from $2,000 to $2,500.

Figure 4: ()

Process-Monitoring Technologies: The FDA’s 2004 PAT initiative laid out a foundation for innovative pharmaceutical manufacturing through process understanding, monitoring, and control, otherwise known as a QbD approach (15). It has recommended and facilitated innovation in analytical technologies.

Supplier companies have developed in-line real-time sensors based on chemical, physical, and microbiological methods. Recent advances and universal acceptance of single-use technologies have led the same vendors to develop either noninvasive or single-use formats. Although most of those sensors were aimed initially towards upstream processes — e.g., measuring pH, dissolved oxygen (DO), glucose, and VCD — their need in DSP has been gradually identified. Most suppliers are currently adapting their sensors for DSP applications by transitioning into a number of new formats, including flow-through.

One of the latest advancements for cell processing is a VCD sensor based on optical density (OD) and capacitance measurement. To help ensure that cell suspensions reach final cell concentration and are ready for formulation, measuring VCD in real time during DSP for cell therapies is as critical as it is in upstream cell culture for bioprocessors. Current VCD measurement technologies from Mettler Toledo and Finesse Solutions measure OD, whereas Fogale Nanotech and ABER Instruments measure capacitance. Cryopreservation Discussion of cryopreservation methods and concerns is beyond the scope of this article. Companies such as BioLife Solutions offer protein-free and serum-free GMP-compliant biopreservation media for cells, tissues, and organs.

BioLife Solutions also offers contract R&D and protocol consulting, as well as custom formulation, fill, and finish for some customers. —Cheryl Scott, senior technical editor

Further Reading

Mathew AJ. I’m Losing Cell Viability and Function at Different Points in My Process, and I Don’t Know Why! BioProcess Int. 8(6) 2010: 54–57.

Rios M. Industry Roundtable. BioProcess Int. 9(3) 2011: S42–S44.

Van Buskirk RG, et al. Hypothermic Storage and Cryopreservation. BioProcess Int. 2(10) 2004: 42–49.

Van Buskirk RG, et al. Cryopreservation: It’s Not Just About Cell Yield. BioProcess Int. 3(4) 2005: 64–72.

Equipment manufacturers are actively looking to provide VCD sensors in a broad range of formats. For example, in-line, disposable, flow-through pressure sensors from Scilog and PendoTech are used in pressure-driven processes such as TFF. Both companies also sell in-line, disposable, temperature sensors, which can be useful for some centrifugation-based DSP (in which controlling temperature helps preserve the quality of cell therapy products). PendoTech and Equflow provide single-use, flow-through sensors that measure fluid flow based on a rotor turning in the flow path.

Companies such as Omega Engineering and Em-tec offer noninvasive flowmeters based on ultrasonic signals. Measurement of accurate fluid flow is critical in characterizing and controlling downstream unit operations in which liquid flow is a key process parameter. Noninvasive air-bubble sensors are also applicable to DSP, in which they can sense accurate and predictable process volumes from upstream unit operations or intermediate downstream steps. Some companies use signals from such sensors to trigger adjacent process steps. Large-Scale Fill and Finish: Scientists and engineers who are passionate about bringing novel technologies to the CTI field face tremendous challenges. As their efforts get under way, new areas in DSP will need to be addressed. For example, in CTI formulation and filling, several liters of concentrated cells probably will need to be formulated in a finite period.

Large-scale fill lines (e.g., the Px system from Aseptic Technologies) and large-capacity, controlled-rate freezers will also be required to process thousands of vials per batch. Fill–finish systems capable of maintaining product quality thus will be required. For large-scale CGMP manufacturing of cell therapies, cold-chain management systems will probably be needed to minimize transient warming events (TWE) in between unit operations. Automated inventory management systems will also become important. Although many efforts are under way to address these issues, they are beyond the scope of our manuscript.

The Foreseeable Future

As CTI lot sizes increase and upstream technologies mature to meet the growing demand of therapeutic cells, manufacturing bottlenecks will shift to downstream unit operations such as volume reduction, cell washing, filling, and freezing. To meet a broad range of final-product requirements, DSP platforms probably will need to be flexible, efficient, and cost effective. Meanwhile, capital and operating costs probably will need to be kept to a minimum for controlling the CoG in larg e-scale therapeutic cell manufacturing. DSP should be able to process hundreds of liters of cell suspension containing hundreds of billions to trillions of therapeutic cells — all the while achieving high concentration factors, product purity, and efficiencies within a timeframe that is considered appropriate for therapeutic cell manufacturing.

TFF and counterflow centrifugation are newly optimized technologies that are both scalable, with the capacity to concentrate and wash 100-1,000 L of cell suspension in a single batch process. TFF is a filtration-based technology that integrates single-use sensors for continuous real-time process monitoring. It is highly flexible for processing small to large volume of cell harvest and can be scaled easily to keep capital and operating costs low. KBI Biopharma’s fully automated kSep centrifugation technology can process high volumes of cell harvest while maintaining critical quality parameters. Its capital investment and the operating costs can be marginally higher than those for TFF, depending on the number of cells processed. Both technologies have the potential to dominate DSP for cell therapies in the near future.

Author Details

Corresponding author Jacob Pattasseril is an engineering manager, Hemanthram Varadaraju is a process engineer II, and LyeTheng Lock is a scientist in cell therapy R&D at Lonza Walkersville, Inc., 8830 Biggs Ford Road, Walkersville, MD 21793; 1-301-898-7025; jacob.pattasseril@lonza.com; www.lonza.com. Jon A. Rowley is an independent consultant, also based in Walkersville, MD.

REFERENCES

1.) Mason, C. 2011. Cell Therapy Industry: Billion Dollar Global Business with Unlimited Potential. Regen. Med. 6:256-272.

2.) Culme-Seynour, EJ. 2012. A Decade of Cell Therapy Clinical Trials (2000–2010). Regen. Med 7:455-462.

3.) Rowley, JA. 2012. Meeting Lot-Size Challenges of Manufacturing Adherent Cells for Therapy. BioProcess Int. 10:S16-S22.

4.) Jones, SD, S McKee, and HL. Levine. 2012. Emerging Challenges in Cell Therapy Manufacturing. BioProcess Int. 10:S4-S7.

5.) Rowley, JA. 2010. Developing Cell Therapy Biomanufacturing Processes. Chem. Eng. Prog.:S50-S55.

6.) Botterill, M. Single-Use Saves Time for Contract Manufacturing Organization.

7.) Langer, E. Budget for Single-Use systems on the Rise: CMOs the Biggest Spenders.

8.) CBER.

9.) Kalmin, ND, and DJ. Brown. 1982. Platelet Washing with a Blood Cell Processor. Transfusion 22:125-127.

10.) Perotti, CG. 2004. A New Automated Cell Washer Device for Thawed Cord Blood Units. Transfusion 44:900-906.

11.) Zeman, LJ, and AL. Zydney. 1996.Microfiltration and Ultrafiltration: Principles and Applications, Marcel Dekker, New York.

12.) van Reis, R. 1997. High Performance Tangential Flow Filtration, Biotech. Bioeng. 56:71-82.

13.) TB032 2003. Protein Concentration and Diafiltration by Tangential Flow Filtration, EMD Millipore Corporation, Billerica.

14.) Scientific and Laboratory Services Introduction to Tangential Flow Filtration for Laboratory and Process Development Applications, Pall Corporation, Port Washington.

15.) CDER/CVM/ORA 2004. Guidance for Industry: PAT — A Framework for Innovative Pharmaceutical Development, Manufacturing, and Quality Assurance, US Food and Drug Administration, Rockville.