Disposable technology for bioprocessing is efficient and cost effective in many product development scenarios. For an industry dedicated to improving human health, however, the environmental contributions of a product must also influence its bottom line. Product transitions evaluated within a people/planet/profit framework require assessment regarding shifts in human and environmental impact. Life-cycle assessment (LCA) offers one perspective by evaluating the environmental loading of inputs and outputs to a product or process. The contribution of individual product life-cycle stages to a total environmental load can be used to inform design of next-generation disposable products and optimize process development when a clear economic preference is not apparent.

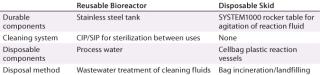

Framework: Disposables are a flexible alternative to conventional bioprocessing equipment for unit operations in which rapid development, space constraints, overhead costs, or maintenance capacity limit the applicability of stainless steel systems. Process comparison models detailing these systems have been developed in previous economic analyses and product flow models (1,2). Such studies parallel what disposables manufacturers and distributors have seen: Economics are a leading factor in the transition to a disposable skid for rapid or supplementary production. Disposable bioreactors also make way for the possibility of production in a completely disposable system. From an environmental perspective, this transition alters both the material inputs to a bioreactor system and the composition of waste that the unit operation generates. Table 1 summarizes the product and process components of conventional and disposable bioprocessing skids.

System1000 skid (WWW.GEHEALTHCARE.COM)

Table 1: Comparing conventional and GE Wave Biotech disposable bioreactor skids

Goals of This Study

Regulatory compliance alone no longer qualifies a process as environmentally responsible. Environmental stewardship, shareholder accountability, and allegiance to company mission necessitate the evaluation of environmental impacts stemming from this shift to disposable products. The LCA presented here was commissioned by GE Healthcare (www.gehealthcare.com) with the goal of understanding the relative human health, ecosystem, and resource impacts of implementing a disposable bioreactor system into a typical bioprocessing scheme (e.g., vaccine or monoclonal antibody production). Specifically this LCA aims to

- Estimate shifts in the distribution of environmental impacts when transitioning from conventional stainless steel bioreactors to disposable systems

- Identify the product or process stages with substantial contributions to environmental load

- Explore opportunities for “greening” disposables through product design, operation, and waste management

- Elucidate shifts in the distribution of environmental burden between the distributor and consumer of biopharmaceutical components.

This LCA targets audiences in research and development of single-use products, sales representatives advising clients on appropriate production skids, and clientele who are conscious of the cost and environmental burden of varying waste streams. The results of this study may also serve as a basis for discussion among designers and consumers of disposable products during next-generation product design.

What Is a Life Cycle Assessment?

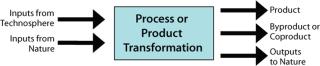

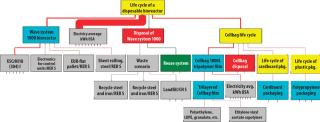

LCA is a “cradle-to-grave” technique for evaluating the environmental impact of a product (Figure 1). Beginning with inputs from nature (virgin materials) and the technosphere (products and coproducts of upstream industrial processes, such as electricity), the LCA assesses a process or product’s whole environmental burden by summing the contribution of its parts.

In addition to addressing inputs of a process, LCA also evaluates its outputs. These are loosely classified as the next product in a process model, a coproduct (e.g., waste heat from bag incineration), or an output to nature (e.g., incineration emissions).

The life stages typically covered include raw-materials extraction, manufacturing, packaging, transport, use, maintenance, and disposal. This holistic approach to product life cycle reduces the tendency for high-visibiltiy life stages to dominate perceptions of environmental impact. This full–life-cycle approach also prevents the transfer of environmental burden from one stage of a product’s life cycle to another during optimization.

The US Environmental Protection Agency outlines the LCA process in four steps. An LCA practitioner defines system boundaries to address intended goals of the LCA, compiles a life-cycle inventory of relevant inputs and environmental releases from a system, classifies and evaluates potential environmental impacts of each product stage, and interpretes LCA results to inform product/process development and decisions made regarding product application (3).

Limitations: As with any modeling tool, LCA is valuable when used properly and misleading when not. A full cradle-to-grave assessment involves thousands of inputs, outputs, and process information, each requiring extensive data collection and verification. Initial screenings and rapid-assessment LCA studies, such as the one presented here, limit their scope by constraining system boundaries and using industry-developed databases to approximate the inputs and outputs of well-defined processes. But pitfalls and errors may arise when a system boundary is too narrowly defined, collected data are misrepresentative of industry averages, or inaccurate assumptions are formulated when data are unavailable. An additional risk lies in the application of LCA results to systems beyond the scope of the original assessment.

Results from a rapid-assessment LCA are particularly subject to error and are thus more relevant for product comparison than for assessing total environmental impact (4). Care must be taken to apply the results of this study to scenarios consistent with the system boundaries outlined below.

LCA Modeling

System Boundaries: Despite the potential pitfalls of the LCA process, a carefully designed study offers a first approximation to the question of environmental impact within established system boundaries. This study evaluates the bioreactor component of a typical bioprocessing scheme for a phase 1 clinical trial product by comparing the traditional stainless-steel option with a GE Wave Biotech disposable skid. The functional unit of reference is a 500-L working-volume, 10-batch production campaign. Waste streams are sent to reuse or recycling whenever possible. Because this analysis aims to elucidate the relative environmental impact of disposable and conventional bioreactors, I do not include the inputs, outputs, and durables that are common to both systems.

Other exclusions from the system boundaries include system components upstream and downstream of the bioreactor; variation in cell growth rate or reaction yield between the systems; process fluids (e.g., buffers and media); personnel and labor requirements; transport of durable equipment including the bioreactor, a clean-in-place (CIP) system, and disposable platform rocker table; a steam–in-place (SIP) system constructed as part of a building’s infrastructure; the plant footprint; and economic factors such as capital depreciation.

Exclusion of those factors is justified because they are not physical components of the bioreactor, because sensitivity analysis suggests they contribute only marginally to the overall environmental burden, or because the impact factors have already been integrated into a plant’s infrastructure such that including them would misrepresent existing conditions in a typical bioprocessing facility. Challenges and drawbacks in defining system cutoffs for a process-driven LCA are reviewed elsewhere (5).

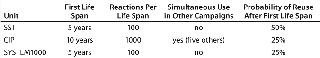

Finally, the magnitude and distribution of environmental loading are sensitive to the life span of durable equipment (e.g., stainless steel tanks, CIP systems, and rocker platforms). Interviews with bioprocessing facility managers indicate that conventional steel tank bioprocessing skids have a 50% chance of being used longer than five years, whereas equipment with electric control units had a 25% chance of being reused in a second five-year life cycle (Table 2). Lengthening the life span of durable components typically diminishes the environmental impact of a process.

Table 2: Life-span estimates for durable equipment in conventional and disposable bioreactor skids

Stainless Steel Bioreactor: Data for the life-cycle inventory (LCI) of a conventional stainless steel bioreactor system came from stainless steel bioreactor and CIP unit manufacturers as well as the EcoInvent 1.3 database (6). Process inputs and outputs are averaged across estimates by industry users and/or sales representatives who are familiar with the systems.

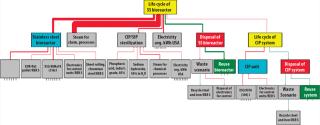

The LCI of a stainless steel bioreactor is presented as a diagram of inputs to and outputs from a product’s life cycle. Figure 2 details the relative environmental impact contribution from processes or material inputs from operating a bioreactor in a 500-L working volume, 10-batch production campaign. The thickness of each flow path represents the environmental load attributed to a particular input. Items in red contribute negatively to the environmental impact; items in green mitigate or reduce the environmental footprint of the system. Inputs that contribute <1% of the total environmental load are not included. Note that the physical components of the SIP system are assumed to be integrated into the standard infrastructure of the biopharmaceutical facility. Thus, only the water and energy contributions from a SIP sterilization process are included in this model.

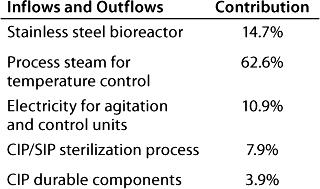

This visualization technique allows for preliminary assessment of a conventional stainless steel bioreactor system. Numerical values for environmental impact by process and system components are reproduced in Table 3. The bioreactor itself constitutes ~15% of the total environmental load under these defined system boundaries. CIP sterilization contributes only 8% of the loading, far less than the 63% contribution from steam generation necessary for temperature control. The electricity required to operate agitation and other system control units contributes 11% of the bioreactor’s environmental load. Similar analyses on subassemblies within the system suggest leverage points for reducing the environmental loading of a conventional stainless steel bioreactor system.

Table 3: Primary contributions to the net environmental impact of a conventional stainless steel bioreactor system

Single-Use System: Input and output data on GE’s ReadyToProcess system manufacturing, use, and disposal are based on the System1000 rocker table and 1,000-L bags distributed by the company’s Wave products group. Disposal techniques for used bags vary significantly among industry users. Incineration as biohazardous waste is the most common strategy for large bags, and it serves as the basis for this model. Other disposal strategies — including autoclaving or chemical deactivation proceeded by shipment to a solid waste landfill — are popular for bags in the 10-L to 50-L size range.

Figure 3 depicts contributions of system component inputs and outputs to the environmental load of a disposable bioreactor skid. Table 4 divides these into contributions from the rocker platform, the disposable bag, and the energy for unit operations. Energy for agitation and temperature control of the disposable reaction vessel accounts for the majority of the disposable skid’s environmental impact. Production and disposal of the nondurable bag contributes about a quarter of the environmental impact.

Table 4: Primary contributions to the net environmental impact of a disposable bioreactor system

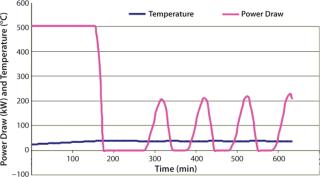

Refinement of the temperature sensitivity of a System1000 rocker during this study decreased the energy demands for system temperature control, and the modeling in this study reflects these product updates. Figure 4 graphs power draw against time for the heating components of the disposable bioreactor.

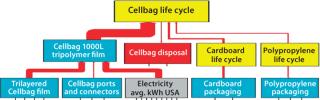

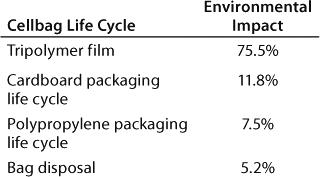

Also noteworthy in this analysis is that the Cellbag manufacturing process dwarfs that of the Cellbag disposal process (Figure 5, Table 5). Model simulations using alternative plastic resins significantly affected the relative environmental impact of the bags, and further analysis of proposed next-generation Cellbag products in the final section of this report. Finally, the durable component (System 1000 rocker) accounts for a significant portion of the disposable system’s net environmental impact.

Table 5: Primary contributions to the net environmental impact of a disposable bag

Impact Assessment

A complete LCI provides the inputs and outputs of a bounded system, whereas LCA attempts to quantify the environmental impacts of each process or material flow. The above-presented flow models used aggregate LCA scores to determine the percent contribution from each product or process. The aggregate scoring method consists of the following (7):

- Classifying the product inputs and outputs into impact categories

- Characterizing the relative contribution of a single substance to an impact category (achieved by applying a characterization factor to normalize each input, output, or process with factors used from the Eco-Indicator 99 (H) V2.04 database)

- Damage assessment of the entire system from aggregated impact categories expressed in equivalent units (the three categories of damage analysis are human heath, ecosystem quality, and resource demands)

- Normalization of categories to the total impact or damage in a given region to estimate the severity of the environmental impact (the Europe EI 99 H/H normalization data set was chosen for its completeness as well as the relative similarity in economic, social, and environmental conditions between Europe and the United States)

- Weighting, the final step, to produce a single environmental score by assigning impact factors to the normalized damage assessment categories (e.g., the Europe EI 99 H/H database weights human health higher than ecosystem quality or resource depletion).

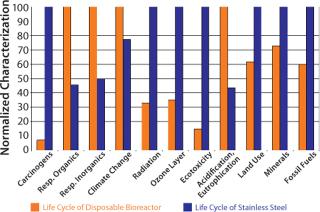

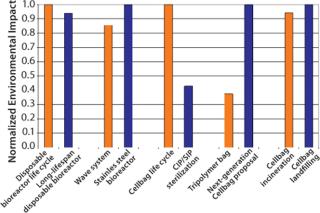

Each of those assessment steps is plagued by some degree of subjectivity. Although my study follows current standards, no “quantitative” LCA can escape the inherent subjectivity of the assessment process. For this reason, the scores obtained are more valuable for comparing product alternatives than for quantitatively assessing the environmental impact of a bioreactor or reaction process. For product comparison analysis, I used SimaPro modeling software (8), the EcoInvent 1.3 database (6), and an Eco-indicator 99 (H) V2.04 / Europe EI 99 H/H normalization and weighting scheme. Figures 6 and 7 present the characterization and weighting plots.

Characterization: The characterization step compares the contribution of two product life cycles within an impact category. Outputs from this process provide relative impact scores normalized to 100%. These scores are informative in optimizing a product’s life cycle to minimize one specific environmental burden, such as global climate change.

This process also aids in product selection on a regional level when one impact category contributes disproportionately to environmental damage. For example, a facility in a highly sensitive watershed may transition to disposables to reduce its ecotoxicological effect from water use in a conventional system.

Alternately, characterization may be performed for specific processes in a product life cycle. For instance, a biopharmaceutical company seeking to reduce its climate change contributions may decide against switching to disposables for its primary manufacturing skid.

Figure 6 characterizes the relative environmental impacts of disposable and conventional bioreactor assemblies for a 10-batch production campaign. This characterization is based on contributions from all processes and products of the system, so it assesses cumulative rather than regional impact.

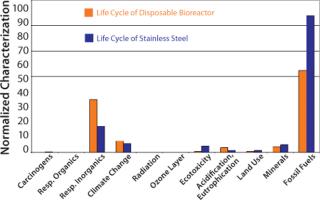

Weighting identifies the impact categories contributing the bulk of a product’s environmental burden following the Europe EI 99 H/H method. Figure 7 displays weighted contributions to environmental impact.

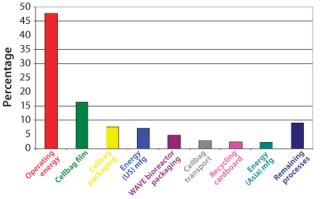

Energy demands (represented by the “fossil fuel consumption” category) account for the bulk of the environmental burden from both bioreactor assemblies. This includes energy of all processes, from raw materials extraction through product assembly to the use phase of each bioreactor. Figure 8 further delineates fossil fuel consumption for the disposable assembly. Although operating energy for the System1000 skid accounts for half of its fossil fuel usage, plastic film extrusion and packaging production also contribute significantly.

Interpretation

LCA is a tool rather than a final product. Data presented here constitute just a small portion of the opportunities for data generation and interpretation. Alternative classification, characterization, and weighting schemes may be tailored to further resolve the regional or process-specific details of environmental impact. Rather than characterize specific scenarios, the remainder of this report uses the tool for informal “hypothesis testing” of current perceptions about the environmental impact of disposable and conventional bioreactor systems. I hope this process will inspire engineers and clients to use LCA methodology to objectively test their assumptions about the extent and distribution of environmental impact in the upstream phases of product development or system design (see the “Common Assumptions” box).

When evaluating the environmental impact of transitioning from conventional to disposable bioreactors, industrial users focus a disproportionate amount of their attention on waste-stream generation. Water and caustic waste from conventional bioreactors is replaced by plastic waste from disposable bags. Although this trade-off is one component of the environmental impact equation, LCA data reveal a more complex series of trade-offs that are not captured by waste stream analysis alone.

In particular, this study has demonstrated that upstream manufacturing processes and operational inputs have a far greater effect on cumulative environmental impact than the process waste stream. Water consumption and caustics use in a conventional system do manifest themselves in a less favorable ecotoxicity score relative to a disposables system, but the life cycle of a plastic bag has a higher total environmental impact than does the life cycle of a CIP/SIP sterilization process. Figure 9 presents quantitative comparisons of other perceived sources of environmental impact.

COMMON ASSUMPTIONS

Common assumptions about the environmental impact of conventional (reusable) systems:

- Environmentally preferable to disposable system

- High water use

- Involves environmentally toxic cleaning agents

- High upfront environmental and economic costs for durable equipment

- Water treatment is difficult. Common assumptions about the environmental impact of disposable systems:

- Greater environmental impact than a conventional system

- Reduced consumption of water and cleaning agents

- Reduced upfront environmental load for disposable skids

- Largest environmental impact from plastic waste accumulation

- Solid waste disposal is environmentally preferable to incineration.

The life cycle impacts of a disposable bioreactor system are reduced as the life span of its components is extended. Figure 9 depicts the reduction of environmental impact as the probability of rocker table reuse in a second five-year life span increases from 25% to 50%.

The initial investments in durables (rocker and stainless steel tank) yields approximately equal environmental impacts for both options. I excluded the CIP system from my analysis because a 10-batch campaign accounts for a mere 1% of its total life span.

The life cycle of a plastic bag has a higher cumulative environmental impact than that of a CIP/SIP sterilization procedure. This impact is distributed between the manufacturing of the film, bag assembly, and packaging. Cellbag packaging may represent a leverage point for reducing the environmental impact of disposable system components.

Next-generation films are being explored as alternate materials for Cellbag construction. Tripolymer films currently have a lower environmental impact than certain proprietary films that are under development. The bulk of additional environmental impacts fall into the category of climate change effects.

Incineration and landfilling of a tripolymer bag have comparable environmental impacts when BTU value is recovered from bag incineration and autoclaving is not performed before waste collection. Transport distances to the combustion and landfill facilities are assumed equal for this study.

Looking at the Full Picture

Perceptions of environmental impact are often inconsistent with the realities of product or process implementation. Hypothesis testing with comprehensive LCA may correct this discrepancy by reducing biased perceptions assigned to visible or stigmatized waste streams. Clear delineation of environmental impacts enhances opportunities to target leverage points for improving the environmental sustainability of product design and process implementation.

This analysis has uncovered nuances in the environmental impact of disposable and conventional bioprocess systems. Neither system is free of environmental impact, but a comparative LCA informs potential shifts in environmental impact that occur with product transitions. Energy consumption during bioreactor use provides opportunities for product redesign in both conventional and disposable bioreactor systems. Insulating plastic bags with heat-reflective blankets, for instance, could further decrease the energy use of a disposable system. Companies may also choose to use green energy sources or purchase carbon credits for abatement of fossil fuel emissions if they wish to further reduce the process-side contributions of a bioreactor’s environmental impact from energy consumption.

The bioreactor is only one component of a disposable skid. Opportunities to design for a completely disposable production train would eliminate the need for a SIP system and reduce the energy demands of cleanroom space. A cursory analysis suggests that these two components may reduce both the environmental impacts of bioreactor skid and the economic costs of construction and facility maintenance.

REFERENCES