Tangential-flow filtration (TFF) cassette operations are known for reusable cassettes; however, a single-use model is less established because production-scale single-use TFF cassettes are not readily available. Novasep (through TangenX Technology Corp.) offers the first presanitized, purposely built, single-use TFF cassette for the biopharmaceutical industry.

Sius™ cassettes have been designed to offer performance comparable with that of reusable products at a fraction of the cost. Each cassette arrives presanitized, ready to be equilibrated with buffer and used for processing. Prior to shipment, each is 100% integrity tested and certified for both low TOC and low endotoxin. Sius™-LS cassettes are available in a range of surface areas from 0.01 m2 to 1 m2, and Sius™ process cassettes range from 0.5 m2 to 5 m2. These cassettes have been developed using an innovative manufacturing approach that provides an efficient production process yielding a single-use cassette costing significantly less than comparably sized reusable products. Most importantly, these cassettes are completely interchangeable with existing cassette hardware, making them an ideal choice for many TFF processes.

Single-Use Economic Model for TFF: Processing 50% FasterDeveloping an economic model for downstream purification process steps is a critical task that is important when scaling a process from bench-top up to process scale. Preparing an accurate economic model must include all critical aspects of the process. Considerations of labor, utilities, and waste contribute to the complexity of such a model. It is here that the benefits of single-use technologies are weighed against traditional reusable equipment. A typical downstream purification process can contain of two to three TFF steps. Under suitable circumstances, a significant amount of time and resources can be conserved when implementing a single-use TFF process.

Sius™ single-use cassettes offer exceptional economic value compared with reusable TFF cassettes: presanitized cassettes are installed, equilibrated with buffer, and used in processing — no need to flush with DI water or measure water permeability rates, which saves time and resources; development work, scale-up, and processing can be conducted nearly 50% faster without the need for membrane cleaning and measurement of water flux recovery; cassette performance is more consistent from run to run because each process occurs using a new membrane; and cross-contamination is minimized using single-use cassettes.

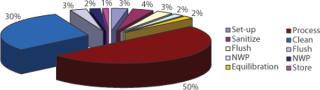

A typical TFF process can be broken down into basic components that include preuse activities, processing, and postuse activities. Figure 1 shows the components of each and assigns them percentages that are proportional to the time required to perform each component. Typically, only 50% of the total process time is devoted to actually processing the product stream. The remaining 50% is spent in preparing and cleaning a TFF system.

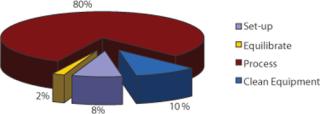

A single-use TFF process can be broken down similarly. Figure 2 shows the components of each activity and assigns each a percentage that is proportional to the time required to perform it. Here, 80% of the total process time is devoted to processing the product stream, which increases process efficiency and saves a significant portion of the overall process time.

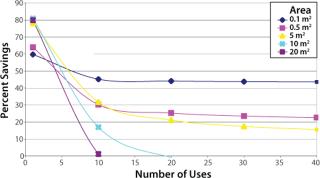

Single-use TFF does have certain economic limitations. Several key factors affect its economy, two of which are membrane area and the number of annual process cycles. Figure 3 shows the relationship between the number of annual process cycles and the percent savings associated with single-use TFF at different process scales. The obvious trend shows that single-use TFF technology is most beneficial at development and pilot scales (<5 m2). Additionally, larger scales benefit when the number of annual process cycles is fewer than 20.