Osmolality is a critical attribute for injectable formulations. It is desirable to have products match physiological osmotic conditions. Furthermore, osmolality provides confirmation of soluble content in solution. Preventing injection of hypo- or hyperosmotic solutions is a key element of parenteral formulation development. Additionally, some investigators have explored correlations between injection pain and formulation osmolality, although no significant correlation has yet been observed (1–4). Osmolality is a valuable in-process test also because it provides a reliable and repeatable value that reflects…

Wednesday, June 15, 2016 Daily Archives

Enhanced Biosimilar Product Characterization: A Case Study Using Raman Spectroscopy Combined with Dynamic Light Scattering

Biophysical characterization has drawn great attention from the biopharmaceutical industry and regulatory agencies across the globe, especially for use in biosimilar drug product development. Currently available biophysical characterization tools can help in screening and optimizing better (more stable) formulations for such products. However, most tools cannot be used for head-to-head comparison of the biophysical properties of an optimized biosimilar formulation with those of an innovator product at higher concentrations. We developed and optimized a formulation for monoclonal antibody MAb B…

A Single-Use, Clinical-Scale Filling System: From Design to Delivery

Single-use components have been successfully incorporated into many unit operations for both upstream and downstream processing, from laboratory scale to commercial manufacturing. The development of single-use filling needles has created an opportunity to introduce fully disposable systems into final formulation and filling of drug products (1). One major challenge in replacing a cleanable filling line containing stainless steel needles is to ensure that an alternative system can satisfy all critical performance parameters established for an existing process. In 2012, Merck…

Single-Use Technology Enables Flexible Factories

The biosimilars market is rapidly evolving, with more than 450 biosimilar molecules in development worldwide, and many anticipated transfers of molecules in process around the globe. With US$85 billion of biopharmaceutical products coming off patent by 2020 (1), the driving force to develop biosimilars is strong. The market will be highly saturated, with dozens of biosimilars currently in development for each current blockbuster molecule. We know of 46 trastuzumab biosimilars and 39 rituximab biosimilars in development. Because the biosimilars market…

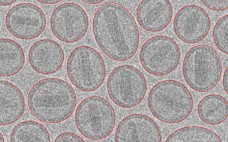

Ask the Expert Liposome and Viral Vector Characterization: Use of Electron Microscopy and Image Analysis

with Dr. Josefina Nilsson For this webcast, Josefina Nilsson (EM Services business unit head) discussed Vironova’s work, including case studies. She focused on characterization of drug and gene delivery platforms with electron microscopy and image analysis, specifically for systems that use viral vectors or liposomes. Along with two colleagues — Gustaf Kylberg (image analysis expert) and Mathieu Colomb-Delsuc (electron microscopist) — she then answered questions from the audience. Nilsson’s Presentation Structural characterization provides important insights into the quality of development and…

Deciding on an Integrated Continuous Processing Approach: A Conference Report

Biopharmaceutical manufacturers are increasingly investigating or implementing continuous processes, and industry experts are participating in vibrant and healthy discussions on a wide range of process approaches being adopted. We seem to have entered a phase within the biopharmaceutical industry (which is often described as conservative) of intense bioprocess innovation as manufacturers strive to lower costs and provide agile, responsive supply chains for “drug on demand” continuous manufacturing operations. Senior industry leaders met in Berkeley, CA, in late 2015 at ECI’s…