Figure 1:

Figure 1:

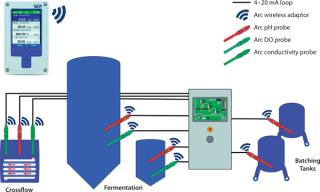

When planning a modern 750-L fermentation plant including a cross-flow unit, the GEA Diessel company was looking for the best available measurement technology suited for its customer requirements. Attention turned to the new intelligent Arc sensors from Hamilton. After testing the Arc system, the plant engineer and GEA’s customer were convinced of the advantages of the new technology, deciding to use the Arc system in the fermentation plant. GEA Diessel and Hamilton were able to supply an accurate and innovative solution to the customer.

Efficiency, compact construction, reliability and precise process controls — these are the requirements for the new GEA.

Diessel Company Fermentation Plant: Process stability and the necessary measurement equipment for the entire plant were especially important for the customer. In using the modern Hamilton Arc sensors, a suitable solution is established. Intelligent measurement data processing and robust, high-quality signals directly from the sensor head are advantages of the Arc system in the fermentation process.

Measurement PointsThe newly constructed fermentation plant contains nine measurement points for pH, dissolved oxygen (DO), and conductivity. The intelligent Arc sensors contain an integrated transmitter and deliver data such as measurement value, sensor quality, operating time, clean-in-place/steam-in-place (CIP/SIP) count, product numbers, calibration data, and much more. Measurement points for pH and DO are placed at both the prefermenter and main fermenter. The optical sensor (VisiFerm DO) is used for DO measurement.

Its maintenance costs are low, because it does not contain any electrolyte and has a membrane that is very resistant to pressure. Furthermore, polarization of the sensor is not necessary. VisiFerm DO Arc does not require any extensions to the sensor, thus the design is very compact, and the ratio of price to performance is unbeatable.

The batching tanks are both equipped with the pH Arc sensor, EasyFerm Plus Arc. The classical version of this sensor is successfully established in fermentation processes. The formulation tank sensor is run by its own control box, connected to the PCS of the production plant when the tank is used. The last stage of production is a cross-flow device equipped with two conductivity sensors (Conducell 4USF Arc) and a pH sensor, the EasyFerm Plus. The compact design and broad measurement range of 1 µS/cm up to 500,000 µS/cm, make the sensor ideal in the downstream area.

Layout and New Operational ConceptThe Hamilton Arc System achieves stable and interference-free 4–20 mA signals from the sensor to the PCS. The cost and required space for transmitters does not have to be considered when planning the plant. Arc View Handheld receives its data by wireless data transmission from every sensor and offers an elegant way to acquire the digital information from Arc sensors. Sensor quality and operational status can be monitored centrally and conveniently with one Arc View Handheld for multiple sensors.

Calibration on site is not necessary because of the integrated transmitter. All sensors can be calibrated conveniently in the laboratory with the Arc View Handheld before the process starts. Calibration data are then stored in the sensor for further use.

User Benefits of Arc Sensors

Simple operation and maintenance with handheld

Little maintenance required

No transmitter needed

Robust 4–20 mA signal

Stable optical oxygen measurement

High-quality product

High measurement accuracy

Wireless sensor management

Sensor quality monitoring

Space savings in the control box

GEA Diessel GmbH, Steven 1, 31135 Hildesheim Germany; 49-5121-7420, fax 49-5121-742-153; www.geadiessel.com.

Hamilton Americas & Pacific Rim, 4970 Energy Way, Reno, Nevada 89502; 1-775-858-3000, 1-800-648-5950, fax 1-775-856-7259; sales@hamiltoncompany.com; www.hamiltoncompany.com

Hamilton Europe, Asia, & Africa, Via Crusch 8, CH-7402 Bonaduz, Switzerland; 41-81-660-60-60, fax 41-81-660-60-70; contact@hamilton.ch; www.hamiltoncompany.com

To find a rep

resentative in your area, please visit www.hamiltoncompany.com/contacts.

Author Details

Dipl. Ing. (FH) Marijan Culina is with GEA Diessel GmbH; Dipl. Ing. Christian Brokamp is with Hamilton Messtechnik GmbH; and Dr. Gleb Zhylyak is with Hamilton Bonaduz AG. © 2012 Hamilton Bonaduz AG. All rights reserved. P/N: 695099/01 — 09/2012