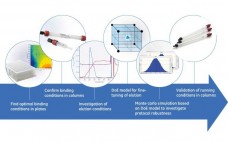

GE Healthcare Life Sciences MAb purification toolbox employs protein A chromatography media (resins) such as MabSelect SuReâ„¢ or MabSelect SuRe LX, in the capture step. After the initial protein A step, there is a range of options for intermediate and polishing purification steps. One option is Capto MMC ImpRes, a new chromatographic medium based on a multimodal cation exchange ligand. This work describes a rapid procedure to establish a robust second step in bind/elute mode for the purification of a…

Monday, April 1, 2013 Daily Archives

T-Cell Suspension Culture in a 24-Well Microbioreactor

Cell therapy promises revolutionary new therapeutic treatments for cancer and other serious diseases and injuries. For example, T-cell therapy response rates of >50% and durable complete response rates of 20% have been reported in patients with metastatic melanoma who had failed other therapies (1). In another example, sustained remissions of up to a year were achieved among a small group of advanced chronic lymphocytic leukemia patients upon treatment with autologous T-cells expressing an anti-CD19 chimeric antigen receptor (2). Numerous other…

Seeding Tissue-Engineered Vascular Grafts in a Closed, Disposable Filter–Vacuum System

Tissue engineering is a multidisciplinary science that applies principles from engineering to the biological sciences to create replacement tissues from their cellular components (1). Resulting neotissues can repair or replace native tissues that are diseased, damaged, or congenitally absent. One technique that has come into widespread use is based on seeding cells onto a three-dimensional (3D) biodegradable scaffold that functions as a cell-delivery vehicle (2). Cells attach to the scaffold, which then provides space for neotissue formation and can serve…

Women Helping Women in Biotechnology

How can we empower women to advance their own careers? How do we encourage entrepreneurship for more female scientists? What will get more girls excited about science? Those are questions that the Women In Bio (WIB) organization seeks to address as it creates programs and networking events across the country. WIB is an organization of biotechnology professionals whose mission is to promote careers, leadership, and entrepreneurship for women involved in life sciences. Started in 2002 as a small support network…

Supporting Continuous Processing with Advanced Single-Use Technologies

It has been 10 years since the US Food and Drug Administration (FDA) articulated — in its guidance for process analytical technology (PAT) — the goal of “facilitating continuous processing to improve efficiency and manage variability” (1). Since that time, regulators and industry have worked toward applying continuous processing (CP) to all facets of pharmaceutical manufacturing, including bioproduction (2, 3). Last year, the European Medicines Agency (EMA) referred to CP in its draft Guideline on Process Validation, and the FDA…

CMC Strategy Forum Europe 2013 6–8 May 2013 — Hilton Old Town (Prague, Czech Republic)

Organized by CASSS, an International Separation Science Society, the seventh annual CMC Strategy Forum Europe will focus on improving quality in development and manufacturing of biopharmaceutical products. Led by experts from global regulatory agencies, academia, and industry, this event series explores emerging aspects of chemistry, manufacturing, and controls (CMC) technology and regulation. The forums are designed to maximize dialog among participants. Relatively short and focused presentations set the agenda for panel discussions that engage all who have experience and expertise…

Single-Use Technology and Modular Construction

To enable broad, global access to life-saving biopharmaceutical products, our industry is facing significant pressure to reduce the overall cost of manufacturing and enable local manufacturing where possible. Combined with growing markets outside the United States and Europe and development of high-titer, high-yield processes, that pressure has led to a shift in the industry’s approach to facility design and construction. Today’s biopharmaceutical production facilities must be flexible, cost effective, and readily constructed with minimal capital investment and construction timelines. As…

Advances in Sensor Technology Improve Biopharmaceutical Development

Today’s biomanufacturing operations require constant management of biopharmaceutical process attributes throughout process development and production. Continuous online measurements of pH, dissolved oxygen (DO), oxidation–reduction potential (ORP), and conductivity (Figure 1) allow real-time industrial process monitoring and adjustment. These functions are crucial to process improvement studies and accurate, reliable manufacturing of high-quality products. Figure 1: () “In the pharmaceutical industry, it is extremely valuable to see how an attribute changes with time and correlate that change with parts of the process,”…

The Influence of Polymer Processing on Extractables and Leachables

Polymers provide a unique set of material properties, including toughness, chemical resistance, versatility, and low cost for both multiple-use and single-use bioprocessing systems. Polymer materials are manufactured as fittings and tubing for research and development (R&D) laboratories, as containers for bulk chemical and biological storage, as filters and separation technologies for downstream processing, and as containers and bottles for drug substance storage. These components and systems are helping drug companies improve their manufacturing flexibility, reduce their operating costs and capital…

Drug Products for Biological Medicines

Traditionally, the CaSSS CMC Strategy Forum meetings have provided a scientific focus on the development of biotech drug substances and their manufacture and characterization, leaving the development of drug product formulation and filling, understanding primary containers, and considering novel delivery systems somewhat out of scope. Over recent years, however, the importance of investing more science and technology into drug product development has become evident as different product types, higher protein concentrations, and doses and requirements for improved delivery of biological…