Xcellerex’s XDRbioreactors are well suited for production processes that require the use of anchorage-dependent cell lines grown on microcarriers. The bioreactor agitation assembly is the driver for these factors. To assure robust bioreactor operation, the M40Eimpeller was designed to perform well above the minimal mixing constraint for uniform gas distribution and fluid homogeneity and well below the maximum shear constraint to assure a viable and productive cell population.

Cell lines such as Vero, MDCK, and MRC-5 are commonly used in production of vaccines or other therapeutic products. These cell lines are anchorage dependent, and they will undergo apoptosis if grown in suspension culture. Mass production of anchorage-dependent cell lines can be accomplished in Tflasks or roller bottles, and the production process can be automated by the use of robotics. However, these methods are laborious and can be prohibitively expensive. Microcarriers are the most common alternative for mass production of anchorage-dependent cell lines producing secreted products. Using microcarriers in an XDRsingle-use reactor makes large-scale culture of these animal cells possible in a way that is efficient, practical, and economical. Cells grow as monolayers on the surface of the microcarriers, which are suspended in culture medium by gentle agitation.

The most commonly used microcarriers are Cytodex 1 and Cytodex 3 currently supplied by GEHealthcare Bio-Sciences. Cytodex 1 is a general-purpose microcarrier formed by substituting a cross-linked dextran matrix with positively charged DEAEgroups distributed throughout the matrix. It is particularly suitable for anchorage-dependent cell lines producing viruses or other secreted cell products. Cytodex 3 is formed by chemically coupling a thin layer of denatured collagen to the cross-linked dextran matrix. Although the source of gelatin used is very well controlled, such construction introduces concern about potential transmissible spongiform encephalopathies from animal sources. So Cytodex 1 is usually the microcarrier of choice for GMP processes.

Results

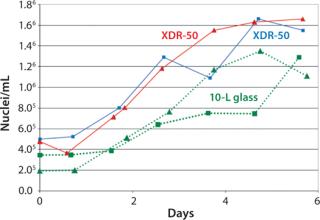

As Figure 1 shows, the XDR-50 with a microcarrier-specific bag assembly enables large-scale culture of anchorage-dependent animal cells. The nuclei/mLcounts are consistently higher than those for a 10-Lglass bioreactor. Anchorage-dependent cells can be cultured efficiently, practically, and economically with Xcellerex’s XDRbioreactors and bag technology. For additional application procedures and specifications, please inquire with xdr@xcellerex.com

Author Details

Patrick Guertin is senior manager—pilot plant operations, Steve Turbane is manufacturing associate III, Geoff Hodge is vice president—process development and technology, Lynda Sefton is application engineer, Edward Hayman is director—cell biology, Justin Bell is manufacturing associate II, and Melissa DiNallo is manufacturing associate at Xcellerex, Inc., 170 Locke Drive , Marlborough, MA 01752; xdr@xcellerex.com; www.xcellerex.com.