LEWA developed its first pulseless pump for liquid chromatography in the late 1970s and delivered its first chromatography system in the early 1980s. LEWA is the leader in supplying pumps used for pilot and industrial HPlC, SMB, and lPlC chromatography worldwide.

A customer came to us several years ago requesting a lowpressure liquid chromatography system with a flow range of 20 − 2,200 L/h. They also wanted the ability to achieve linear gradient from 1 to 99%. We designed and built the system, and it is now in a validated process. This was a very challenging task. Upon completion, this question was asked: “is there a better way?” The intellidrive technology is the answer. LEWA has now integrated this technology into chromatography skids.

The LEWA EcoPrime brings wide dynamic flow range, low-pulsation flow, and accuracy to modern chromatography as unique features. We have combined state-of-the-art functionalities into one unit: it can be a buffer dilution skid, or directly connected to a column to be a chromatography system. This system has been optimized to enhance the purification process. Moreover, due to its dynamic range, it is able to bridge the gap between research and development, process development, and production functions because one single unit covers all three stages. It combines all processrelevant accessories, ensures high reliability, and uses new flow technology that allows for self-cooling, ventilation-free pump motors.

Advantages of LEWA EcoPrime include unrivaled accuracy; constant backpressure for increased precision; dynamic flow range of 1:150; significant reduction in pulsation and hold-up volume; LEWA diaphragm metering pumps reduce shear on protein solutions; design conformity with all pharmaceutical requirements; 0.5–99.5% step and linear gradient capability; state-of-the-art instrumentation; advanced bubble trap design for optimal degasification; 100% drainable and CIP capable, optional SIP capability; and longer life of column media due to minimal pulsation.

Because production requirements may be different, LEWA can custom design a combination of pump types and flows to meet your requirements. The heart of LEWA EcoPrime is the pump technology. The LEWA intellidrive technology pump package is designed to enhance the performance and reproducibility of our pumps. The intelligent drive increases the precision of LEWA Ecodos pumps to ±0.5% and maximizes the pumps’ flow range.

LEWA’s bubble-trap design decreases the hold-up volume while reducing the residence time of the gradient and samples. This allows better symmetry and reduces back-mixing. LEWA provides all documentation to show that the materials used to build the system are all traceable back to their original sources. Moreover, all plastic materials are USP Class VI certified. Regulatory authorities expect manufacturers of pharmaceuticals to qualify equipment before using it in production. LEWA can provide you with validation documentation. Also, LEWA can perform the actual qualification of the system on-site.

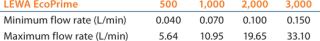

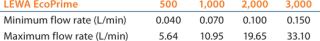

Table 1: LEWA has four platforms to meet your downstream requirements.

LEWA EcoPrime offers commercial and technical performance certainties; IQ/OQ documentation and execution; CGMP compliance from DQ, IQ/OQ to SAT until final acceptance; in-house design, process, and automation engineering compatible with all SCADA systems; and an audit trail to achieve 21 CFR part 11 compliance.

The control of the system will be divided into three main components: control modules, sequences and operation.

Control modules set the parameters for flow, gradient, pH/conductivity, and dilution. These modules are used in sequences, which are methods designed for common chromatography processes such as water flushing, buffer priming, equilibration, product loading, column washing, product elution, column sanitization, fractionation elution, and fraction detection and collection. Ten operations can be stored and recalled. Each operation can contain up to 20 sequences.

Table 1: LEWA has four platforms to meet your downstream requirements.

LEWA EcoPrime offers commercial and technical performance certainties; IQ/OQ documentation and execution; CGMP compliance from DQ, IQ/OQ to SAT until final acceptance; in-house design, process, and automation engineering compatible with all SCADA systems; and an audit trail to achieve 21 CFR part 11 compliance.

The control of the system will be divided into three main components: control modules, sequences and operation.

Control modules set the parameters for flow, gradient, pH/conductivity, and dilution. These modules are used in sequences, which are methods designed for common chromatography processes such as water flushing, buffer priming, equilibration, product loading, column washing, product elution, column sanitization, fractionation elution, and fraction detection and collection. Ten operations can be stored and recalled. Each operation can contain up to 20 sequences.

Author Details

Gary Gaudet is the clean market manager for LEWA pumps + systems (a member of NIKKISO, creating fluid solutions) LEWA, Inc., 132 Hopping Brook Road, Holliston, MA 01746; 1-508-429-7403; fax 1-508-429-8615; sales@lewa-inc.comwww.lewa-inc.com