With a renewed acceptance of perfusion processesin cell in culture, both in the laboratory and for production applications (1), New Brunswick packed-bed bioreactors using Fibra-Cel® disks are seeing an upsurge in interest. This article examines Fibra-Cel technology and its many advantages, from increased yields of secreted proteins to labor savings in applications ranging from rabies vaccine production to production of the first licensed gene therapy drug.

What Is Fibra-Cel?

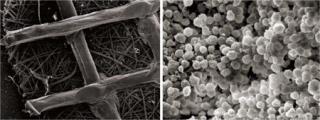

Fibra-Cel from New Brunswick Scientific (Edison, NJ) is a solidsupport growth matrix (Figure 1) for anchorage-dependent and suspension cell cultures. It is used predominantly in perfusion processes for the production of secreted products — such as recombinant proteins and viruses — and it is currently being evaluated for stem cell research (2).

Since the 1980s, scientists around the globe have been using Fibra-Cel to grow a wide range of cell types (see box, right), including hybridomas and insect cultures. Originally used in New Brunswick’s autoclavable CelliGen® cell culture bioreactor — the precursor of today’s CelliGen 310 unit — Fibra-Cel technology has now been successfully scaled up for commercial production in sterilizable-in-place systems as large as 75 liters. New CelliGen BLU packed-bed, single-use vessels containing Fibra-Cel are also in development for those who prefer the advantages of a disposable system.

Manufactured according to cGMP guidelines, Fibra-Cel is composed of two layers of nonwoven material — polyester and polypropylene — which are sonicated together, cut into disks, and electrostatically treated to attract cells and facilitate their attachment to the disks. Normally it takes about six hours for cells to attach to microcarriers (with a normal inoculum of 1 × 106 cells/mL), whereas cells can attach within 15–60 minutes on Fibra-Cel disks. Moreover, the growth process for microcarrier cultures can require extended delays for periodic stoppage of stirring to allow time for cells to become attached. By comparison, the Fibra-Cel bed is inoculated (3 × 105 cells/mL of bed volume) in a single step.

Fibra-Cel in a New Brunswick bioreactor is also advantageous over microcarriers because it enables sustained long-term periods of high-density growth in perfusion mode, without danger of clogging because there are no filters. Perfusion is a mode of cell culture in which a fresh nutrient medium is continuously added to the culture while simultaneously removing the spent medium that contains the product of interest. In a New Brunswick bioreactor, cells growing on or in the Fibra-Cel disk bed are retained within the vessel, inside the packed bed, where they continue the production of the desired product.

Cells Successfully Used on Fibra-Cell Disks

Hybridoma: DA4.4, 123A, 127A, GAMMA, 67-9-B

Anchorage-Dependent: 3T3, COS, human osteosarcoma, RC-5, BHK, Vero, CHO, rCHO-tPA, rCHO (hep B surface antigen), HEK 293, rHEK 293, rC127 (hep B surface antigen), normal human fibroblasts, stroma, hepatocytes

Insect Cells: Tn-368, SF9, rSF9, Hi-5

The packed bed comprises two horizontally positioned screens that extend to the bioreactor vessel walls. Enclosed between the screens, a bed of Fibra-Cel disks serves as solid support for the growing cells (Figure 2). Cells growing in the disk bed become immobilized on or between the disks, where they remain throughout the culture run, protected from external shear forces. The process is favored for manufacturing because product yields can be increased by as much as tenfold over comparable processes (3). Once the bioreactor is set-up and inoculated, the culture can be maintained to produce proteins for long periods of time thus saving labor, time, and money.

Like New Brunswick’s proprietary Cell Lift impeller, rotation of the discharge ports in the proprietary packed-bed impeller creates a low differential pressure at the base of the impeller tube, which circulates the medium throughout the system. The medium receives gases through a sparger located at the bottom of the inner tube, protecting the cells from being exposed to the gas liquid interface. This results in low turbulence and low shear stress on the culture. Exceptionally high cell densities are achievable due to the high surface-to-volume ratio provided by the disk bed, coupled with the ability to use perfusion. In comparison with other cell support systems, it was found that higher titers and cell densities were achieved in trials using Fibra-Cel disks (4).

Other Benefits

Because higher yields are possible, smaller bioreactors can be used to substantially reduce the initial capital expenditure as well as reduce the utilities required for operation (such as electricity, water, and steam if required). In addition, because the cells remain entrapped, the packed bed eliminates the need for cell filtration to separate cells from the end product, thus simplifying harvesting. Last, product recovery and downstream processing can be more easily controlled because users can determine the volume of harvest material that is to be processed at any given time.

Commercial Production

Bioreactors using Fibra-Cel have been used in the production of a variety of commercial products. One example is Gendicine®, the world’s first licensed gene therapeutic drug, which was developed in China by Shenzhen SiBiono Genetech Co., Ltd (Shenzhen, China). Gendicine is an anticancer treatment used to treat head and neck squamous cell carcinoma (HNSCC). Specifically Gendicine is a replication-incompetent, recombinant human adenovirus engineered to contain the human wild-type p53 tumor-suppressor gene and is produced by the SBN-Cel cell line, which was subcloned from the human embryonic kidney (HEK) cell line 293. Af

ter scaling up the process from roller bottles, New Brunswick’s bioreactor with Fibra-Cel technology was selected over a competitor’s system because it produced 15× greater yields of viral particles (5).

Other examples of commercial production include end products such as EPO, which can now be commercially produced on the bench using Fibra-Cel technology, eliminating the need for labor-intensive and space-consuming roller bottles. A substantial portion of the world’s human rabies vaccine is also produced using New Brunswick’s Fibra-Cel technology. Additionally, many of our customers are currently using Fibra-Cel in their proprietary processes to produce interferons, diagnostic test kits, monoclonal antibodies, and hormones.

In summary, Fibra-Cel provides benefits in research laboratories as well as in commercial production. Our customers have found that because yields are high, bioreactors containing Fibra-Cel packed beds can outperform much larger-sized bioreactors, thereby achieving commercial-scale production in a bioreactor with a far smaller footprint. Production space requirements are reduced, as are costs associated with labor, start-up, and operations.

Trademarks: Fibra-Cel® is a registered trademark owned by Celite Corporation and licensed to New Brunswick Scientific Co., Inc. USA. CelliGen® is a registered trademark of New Brunswick Scientific Co., Inc. USA. The New Brunswick Logo™, and the New Brunswick Logo with Flask design are pending trademarks of Eppendorf AG (Germany). Gendicine® is a registered trademark of Shenzhen SiBiono GeneTech Co., Ltd (China).

Author Details

Julia Cino, PhD, is research and development manager; Rich Mirro is executive director of bioprocessing portfolio management; and Suzy Kedzierski is marketing communications manager for New Brunswick Scientific, PO Box 4005, Edison NJ; bioinfo@nbsc.comwww.nbsc.com.

REFERENCES