As production facilities strive for greater efficiency, a common practice is to seek process improvements in quality control (QC) operations. All production facilities share some common requirements for these QC checks, especially that they can be fast, simple, proven, and economical. In addition to this, the production of biological materials such as proteins frequently presents additional requirements, including the need to perform QC tests using very small volumes and the ability to measure the protein product at strength without dilution. The NanoDrop 8000 was designed and tested with these criteria in mind. Traditional spectrophotometry methods are cuvette based; however, the use of cuvettes is in many ways highly undesirable. By creating a liquid column using only a 2-µl sample (Photo 1), NanoDrop spectrophotometers eliminate the need for cuvettes, circumventing the limitations of traditional spectrophotometry, including the need for dilutions.

Photo 1:

Speed

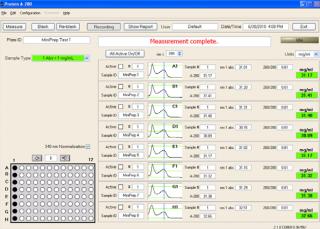

Traditional spectrophotometers require a warm-up period, are slow to take measurements, measure only one sample at a time, and require time-consuming cleaning of cuvettes between samples and interpretation of results. The NanoDrop 8000 requires no warm-up time, measures up to eight samples at once in less than 20 seconds, needs only a quick wipe to clean between samples, and presents data in a simple format with no need for interpretation (Figure 1).

Simplicity

Unlike traditional spectrophotometers, the NanoDrop 8000 includes simple hardware and user-friendly software. This means that users require minimal training, although the integrated custom method capability can be used to remove any chance of an operator accidentally changing settings.

Dynamic Range

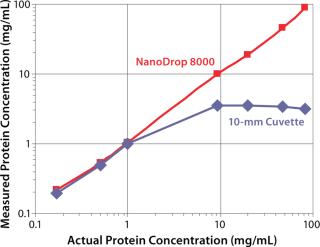

By using a liquid column instead of a cuvette, the NanoDrop 8000 can measure at three pathlengths (0.2, 0.5, and 1 mm), automatically selecting the best. By doing so, the NanoDrop 8000 can measure a far greater protein concentration range (Figure 2), whereas traditional cuvette-based spectrophotometers require sample dilution to a usable concentration.

Microvolume Measurements

Protein production frequently involves the concentration of proteins; the use of samples as small as 2 µl presents the opportunity for significant savings in QC costs. This facilitates the introduction of additional QC steps at multiple production stages without excessive loss of precious product.

The Production Environment

In production environments, space is often at a premium. The NanoDrop 8000 footprint is a little larger than a sheet of letter paper and can be operated using any PC (Photo 2). In addition to service plans including preventative maintenance, an IQ/OQ kit is available for users requiring documented validation.

Photo 2:

Author Details

Andrew Page, PhD, is applications manager for NanoDrop products at Thermo Fisher Scientific, 3411 Silverside Road, Bancroft Building, Wilmington, DE 19810; andrew.page@thermofisher.com, www.thermofisher.com/nanodrop.