Demand for single-use bioprocess systems in the biotech and pharmaceutical industry has increased significantly in recent years. Among other reasons — such as operations, sourcing, and validation — their lower initial investment capital makes disposable systems very attractive for the pharmaceutical industry.

When Wave Biotech introduced the first wave-action reactor/mixer, it was seen by some as the start of single-use technology. Once containers become single-use, all other parts of the manufacturing process ideally have to follow the same principle. These include connectors, tubings, pumps, ultrafiltration/diafiltration (UF/DF) devices, and last but not least: sensors.

Whereas the use of plastic containments is a fairly new development for manufacturing processes, in diagnostics it has been common for decades. The first microplates were made by PMMA in the early 1950s. PreSens offers pH and oxygen sensors for the whole choice of disposable systems ranging from microplates to tubes and bags.

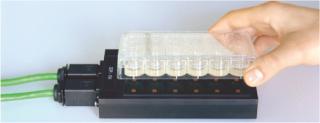

Sensors in MicroplatesFor the first time, the SensorDish® reader (Photo 1) allows noninvasive measurement of oxygen and pH in microplates under an incubator atmosphere. The optical sensors are located at the bottom of each well and are read out noninvasively by a SDR Sensordish® reader. Thus, both process parameters can be monitored on-line conveniently for the entire cultivation. The SDR unit is placed inside the incubator to ensure on-line monitoring under defined levels of temperature, humidity and CO2.

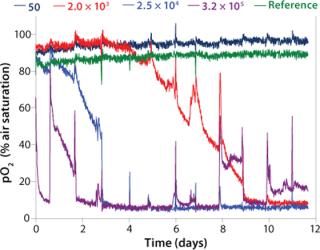

Photo 1.The specimen application shown in Figure 1 monitors oxygen levels of suspension-adapted CHO (CHO-S) cell cultures (1). Special cell lines of these CHO cells have become the standard for production of biopharmaceutical proteins. This is because of their fast reproduction rate, their high protein expression rate compared with other eukaryotic cells, and above all the glycolization pattern they generate. Preconditions for efficient production of correctly processed proteins are optimized cultivation parameters.

Figure 1 shows the dissolved oxygen (DO) measured at different starting cell concentrations. Even handling difficulties such as the removal of cells during media changes can be detected. The purple kinetic after day one shows accidental removal of cells at medium change, which is quite common when handling suspension cultures.

Deeper Insight into Stem Cell CultureAnother field of application of the SDR SensorDish® reader is stem cell research. Here, exactly defined oxygen contents can be monitored precisely and, if necessary, regulated during in vitro development. Controlled cell differentiation in hypoxic conditions can be performed with greater security. Furthermore, the precise detection of oxygen kinetics permits new applications in pharmacology and toxicology (e.g., using HeLa cells or primary cell lines).

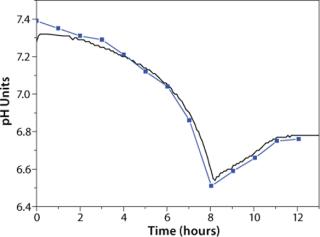

Sensors in Shake flasks: Measuring without Stopping and SamplingPreSens offers systems for measuring oxygen and pH in shake flasks. Shake-flask cultures are widely applied in academic and industrial bioprocess development. As adequate methods for real monitoring of DO were missing, sufficient oxygen supply is usually assumed. The DO sensor spots by PreSens now help to ensure sufficient oxygen supply and give new insights into metabolic activity (2). Monitoring pH is also essential in nearly every biopharmaceutical manufacturing process. As shown in Figure 2 the PreSens sensors now permit precise pH monitoring on a small scale, as in shake flasks (3).

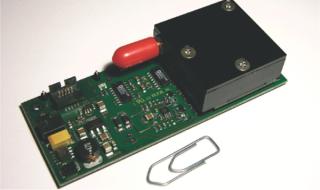

PreSens Precision Sensing has been selling oxygen sensor systems since 1997. Today it is the leading supplier of noninvasive oxygen and pH sensors to the biomanufacturing industry. OEM transmitters have been integrated into controllers by a multitude of manufacturers (4). Sensors are an integral component of bags and other containers. The advantage is that no breach of sterility is required for read-out. Integrated control of sensor integrity ensures long-term stability of measurements.