Trust, competence, and motivation are the major characteristics of a reliable contract manufacturer for clinical projects. At Miltenyi Biotec, customers have more than just projects: they have goals that Miltenyi Biotec helps them to achieve. Miltenyi Biotec is a midsized biotechnology company, focused on medical devices, equipment, and therapeutics for R&D and clinical applications. The product expertise includes GMP-grade antibodies, peptides, growth factors, cytokines, aphaeresis materials, and cellular products, resulting in a broad and significant understanding of different manufacturing challenges. Miltenyi Bioprocess, the contract manufacturing business unit, offers customers comprehensive GMP-compliant contract manufacturing services that encompass the entire life span of their products, from early stage clinical trials to commercial supply.

ManufacturingMiltenyi Bioprocess manufacturing services for prokaryotic and eukaryotic cells start with cell banking and cover process development, USP, DSP, and final vial fill and finish. The manufacturing facility has over 5,000 m2 of laboratory and cleanroom areas, ranging from production in class D up to class A environments. The professional and highly trained personnel use their expertise in development and pharmaproduction as well as in regulatory affairs and quality assurance to achieve the highest possible product quality.

Miltenyi Bioprocess cGMP services in class C (class 10,000) cleanrooms include mammalian cell-line adaptation to protein-free or serum-free media (in-house media available); selection of high-producer cell lines; master and working cell banking (MCB/WCB); upstream process development (USP); batch, fed-batch, and continuous perfusion cell cultivation (up to 200-L working volume); downstream process development and processing (DSP); and protein conjugation.

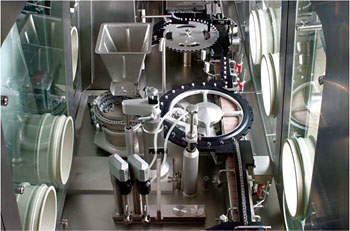

Miltenyi Bioprocess offers pharmaceutical production capabilities in addition to bulk manufacturing. The automated filling line is located in a class A (class 100) hard-wall isolator, which includes a lyophilizer and a crimping robot for the aseptic filling of injection vials. The system also includes an automated hydroxide peroxide steam (HPS) cleaning apparatus and requires no product-specific cleaning validation because of the use of disposable systems. Aseptic capacities are filling of up to 25,000 2R vials per batch and lyophilization of up to 4,500 2R vials (2,200 10R) per batch. A unique feature of the filling line is its capability to fill small lots with a special regard to clinical trials. The very low volume loss of the system allows for filling even very small lots with low volumes — with an economical advance for customers.

By using the well-established CliniMACS® cell separation system for clinical-scale separation and manufacturing of cells and products for cell therapy applications, Miltenyi Biotec offers its professional and extensive knowledge and GMP facilities for customized development and production of cell separation products. Covalent coupling under GMP conditions of monoclonal antibodies or recombinant proteins to Miltenyi Biotec’s unique MicroBeads (50 nm in diameter) is performed under an ISO 13485 quality system as described in an US FDA Type II Device Master File. An indirect coupling system may be used initially to optimize the purity and yield of custom target cells. Proprietary custom antibodies can easily be assessed using this approach. In addition, reactors are adaptable and open for any alternative products and technologies. The Miltenyi Biotec team is a competent whole-process partner for OEM magnetic beads projects, for manufacturing of affinity biomolecules as well as purification, coupling, aseptic filling, and distribution.

Product quality and customer satisfaction are primary objectives at Miltenyi Biotec, supported by a quality system certified according to ISO 9001 and ISO 13485 regulations and compliant with ICH EU and US regulatory guidelines. Miltenyi Biotec holds a manufacturing license for the production of biopharmaceuticals. Its pharmaceutical production is licensed for the production of human drugs according to §13 AMG and has been successfully audited by various regulatory authorities and customers. Thus, the company is valued as a safe and trustworthy manufacturer with a regulatory affairs department experienced in both contract manufacturing support and special regulatory process requirements (e.g., drug master files) Several successful manufacturing and filling projects as well as OEM magnetic separation products prove the ability of Miltenyi Biotec to exactly meet customer needs.